Detection method for primary indicators of concrete aggregate

A detection method, the technology of concrete aggregate, applied in the direction of using material absorption and weighing, etc., can solve the problems of poor timeliness of concrete aggregate, and achieve the effects of improving timeliness, shortening soaking time, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

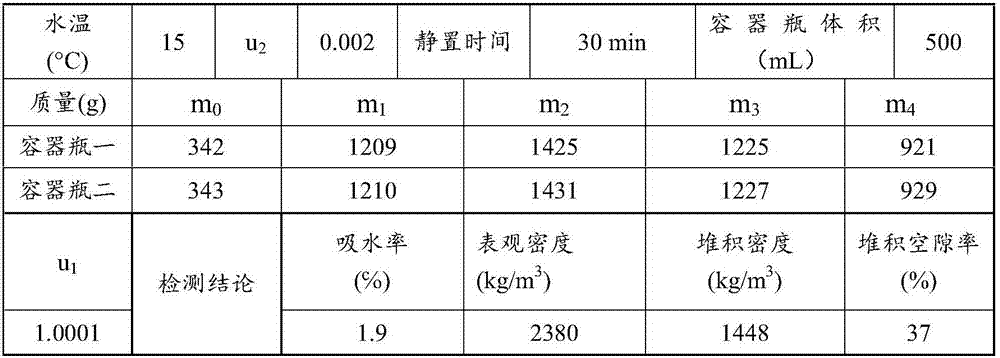

Embodiment 1

[0038] Concrete aggregate contains different types, mainly including fine aggregate and coarse aggregate, the particle size of fine aggregate is below 4.75mm, and the particle size of coarse aggregate is above 4.75mm. The specific implementation of the present invention will be described below by taking the fine aggregate in the concrete aggregate as an example.

[0039] A method for detecting main indicators of fine aggregates during natural accumulation, the main indicators include water absorption, apparent density, bulk density and bulk void ratio, characterized in that the method comprises the following steps:

[0040] Step 1: Sampling the fine aggregate and drying it for later use;

[0041] The second step: take a 500ml empty glass container bottle and glass flakes, the total mass of the empty glass container bottle and the glass flakes is m 0 , take the fine aggregate dried in the first step, fill the empty glass container bottle to be higher than the glass container b...

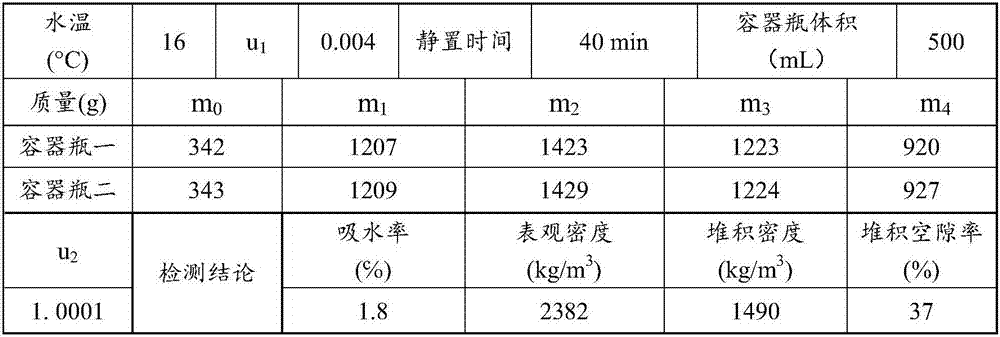

Embodiment 2

[0069] On the basis of Example 1, the standing time was 40min, and other conditions were unchanged.

[0070] Table 2 Test results of fine aggregate technical indicators of natural accumulation

[0071]

[0072] It can be seen from Table 2 that when the standing time is 40 minutes, the water absorption correction coefficient of fine aggregate remains unchanged, the water absorption rate increases slightly, the apparent density and bulk density do not change much, and the bulk void ratio does not change.

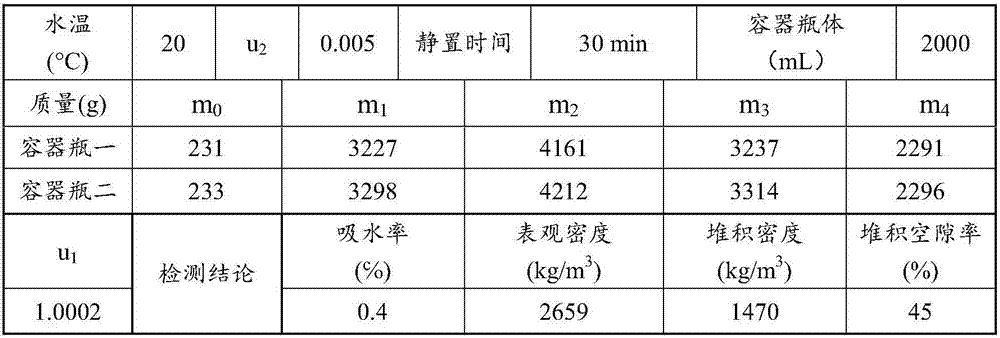

Embodiment 3

[0074] On the basis of Example 1, the fine aggregate is replaced by coarse aggregate, the temperature of the clear water is 20°C, and other conditions remain unchanged.

[0075] Table 3 Test results of natural stacked coarse aggregate technical indicators

[0076]

[0077] Table 3 shows the test results of the coarse aggregate under the conditions of Example 3. From Table 3, we can see that the static time is 30min, the water temperature is 20°C, the water temperature correction coefficient increases to 0.005, and the water absorption correction coefficient u of coarse aggregate 1 The value increased to 1.0002, weighing m 0 , m 1 , m 2 , m 3 , and m 4 Through the formulas of water absorption, apparent density, bulk density, and bulk void ratio, their specific values can be calculated quickly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com