Burning surface identification-based solid propellant burning rate identifying method

A solid propellant and identification method technology, which is applied in the field of solid propellant burning rate identification based on the burning surface mark, can solve the problem that the engine propellant cannot be truly simulated, and achieve the effects of increased efficiency, reduced cost, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

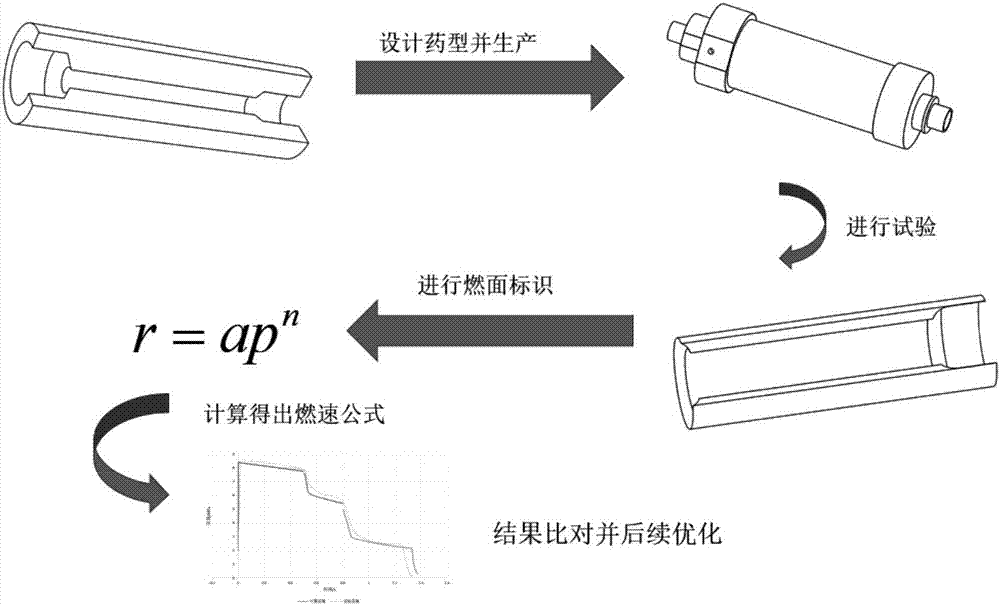

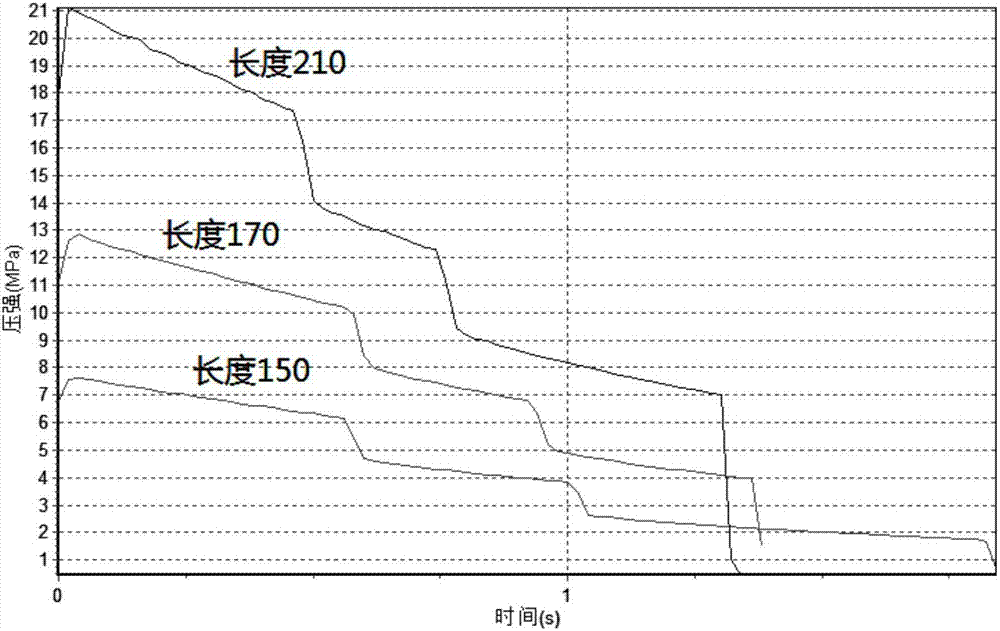

[0031] Based on the traditional engine method, a new type of drug is designed for ground test, and the pressure-time curve is obtained. According to the curve, the characteristic points are selected to mark the burning surface, and the burning rate in the segmental pressure can be solved by using the basic formula and the burning rate can be obtained. expression, the process is as figure 1 .

[0032] The specific instructions are as follows:

[0033] (1) Drug type design

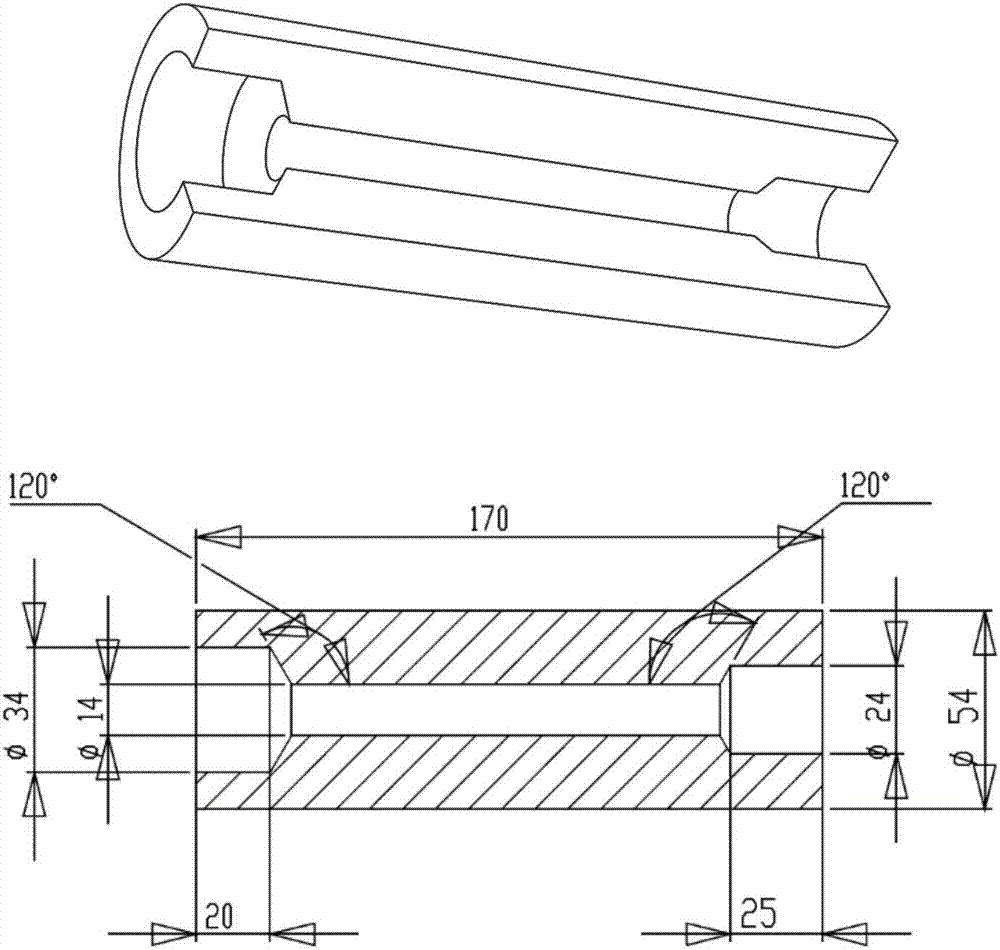

[0034] The drug column used in the traditional engine method is generally a full-surface combustion tubular charge. The burning surface at a certain point in the combustion process of this drug type cannot be determined. An improvement plan for the drug type is proposed here. The drug type designed in the present invention is also a tubular charge, but the difference is that the diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com