Cross-project defect prediction method based on semi-supervised clustering data screening

A semi-supervised clustering and data screening technology, applied in the direction of electrical digital data processing, error detection/correction, software testing/debugging, etc., can solve problems such as lack of high reliability and limited historical data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

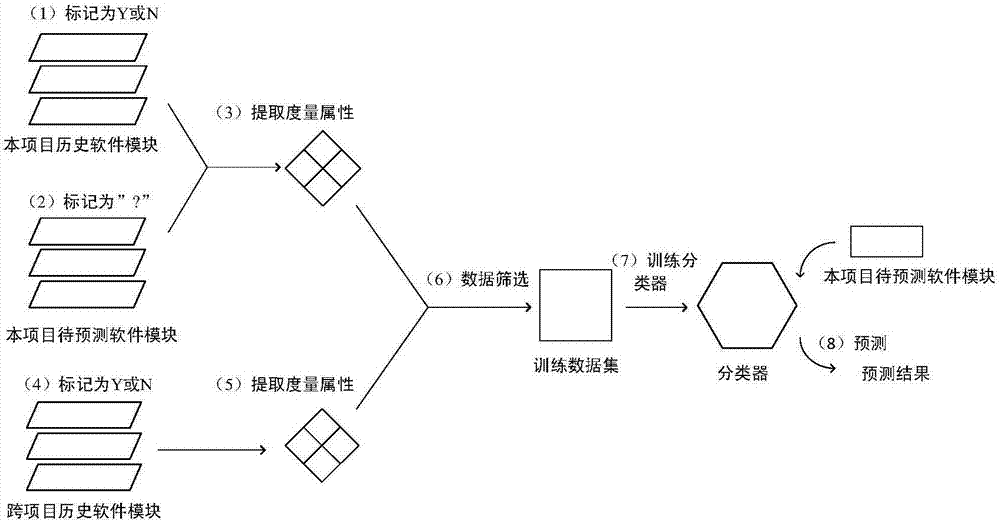

[0029] The specific implementation process of the embodiment of the cross-project defect prediction method based on semi-supervised clustering data screening designed by the present invention is as follows:

[0030] Step 1. Mining the software history warehouse of this project and extracting useful software modules from it. The granularity of software modules can be set as files, packages, classes or functions according to actual application scenarios. Mark whether all the software modules of this project are defective, the class label of the software module marked as defective is Y, and the class label of the software module marked as non-defective is N.

[0031] Step 2, extract the existing software modules to be predicted in this project. These project software modules to be predicted are marked with "?".

[0032] Step 3, extract the measurement attributes of the software modules of this project, and extract 20 measurement attributes: the number of weighted methods (wmc),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com