Conductive silver paste applied to preparation process of solar cell

A technology of solar cells and conductive silver paste, applied in the field of chemical materials, can solve the problems of line expansion, stress damage, thermal expansion coefficient mismatch, etc., and achieve the effect of avoiding line expansion, thermal expansion coefficient matching, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

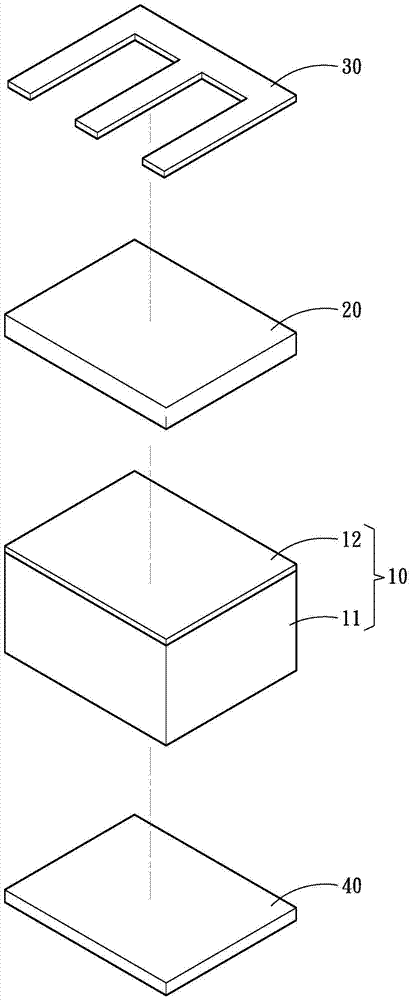

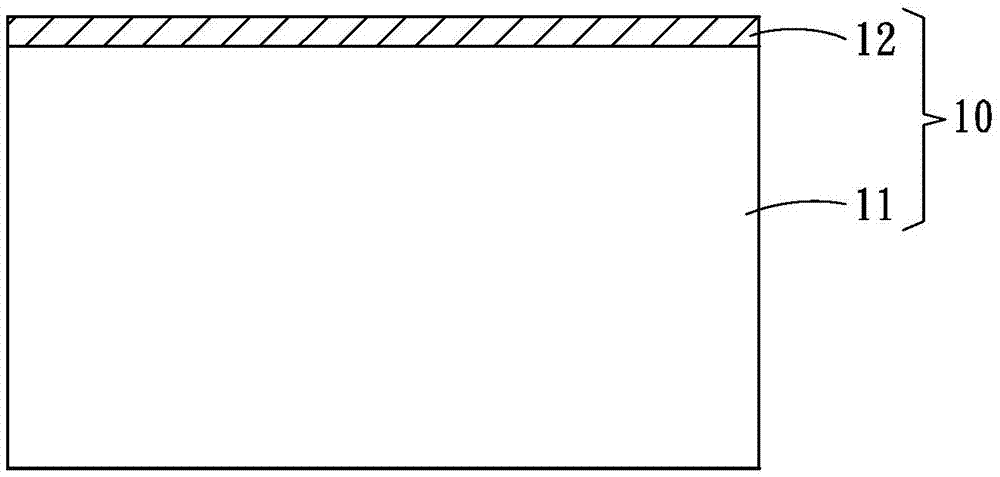

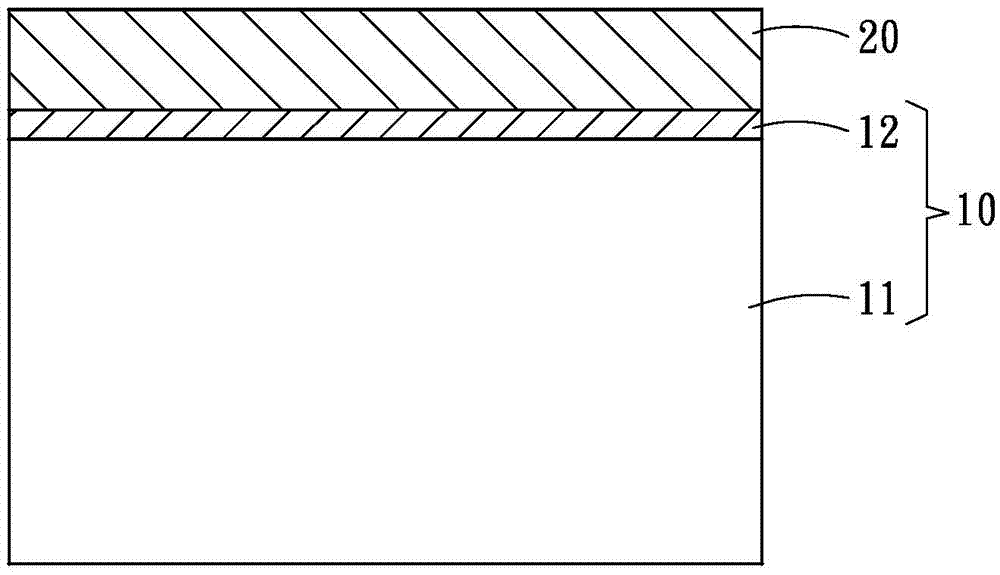

[0028] Relating to the detailed description and technical content of the present invention, it is now described as follows in conjunction with the accompanying drawings:

[0029] The invention provides a conductive silver paste used in the preparation process of solar cells, comprising an organic carrier, a conductive material, a glass medium and a silver precursor, the conductive material, the glass medium and the silver precursor are dispersed separately in the organic carrier. In the present invention, the type of the silver precursor can be silver monoxide (AgO), silver oxide (Ag 2 O), silver nitrate (AgNO 3 ), silver iodide (AgI), silver bromide (AgBr), silver chloride (AgCl), silver fluoride (AgF) or a combination of the above, and the weight percentage of the silver precursor in the conductive silver paste is between 0.01wt .% to 10wt.%. The present invention utilizes adding the silver precursor, when the conductive silver paste containing the silver precursor is sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com