Chip bonding device and method

A chip bonding and chip technology, used in transportation and packaging, conveyor objects, electrical components, etc., can solve the problems of low yield of flip-chip bonding devices, difficulty in meeting mass production requirements, and low yield, etc. Yield, improve efficiency, ensure the effect of bonding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

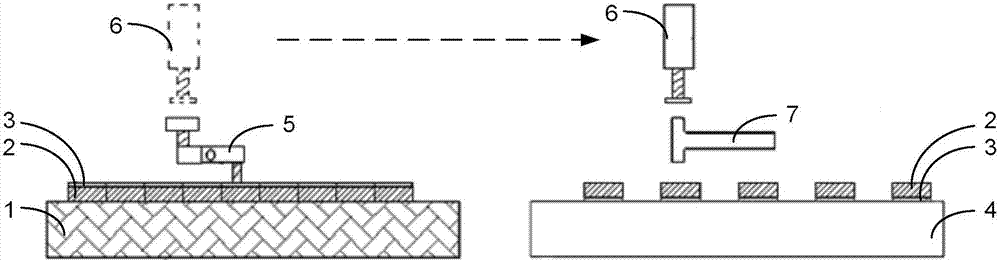

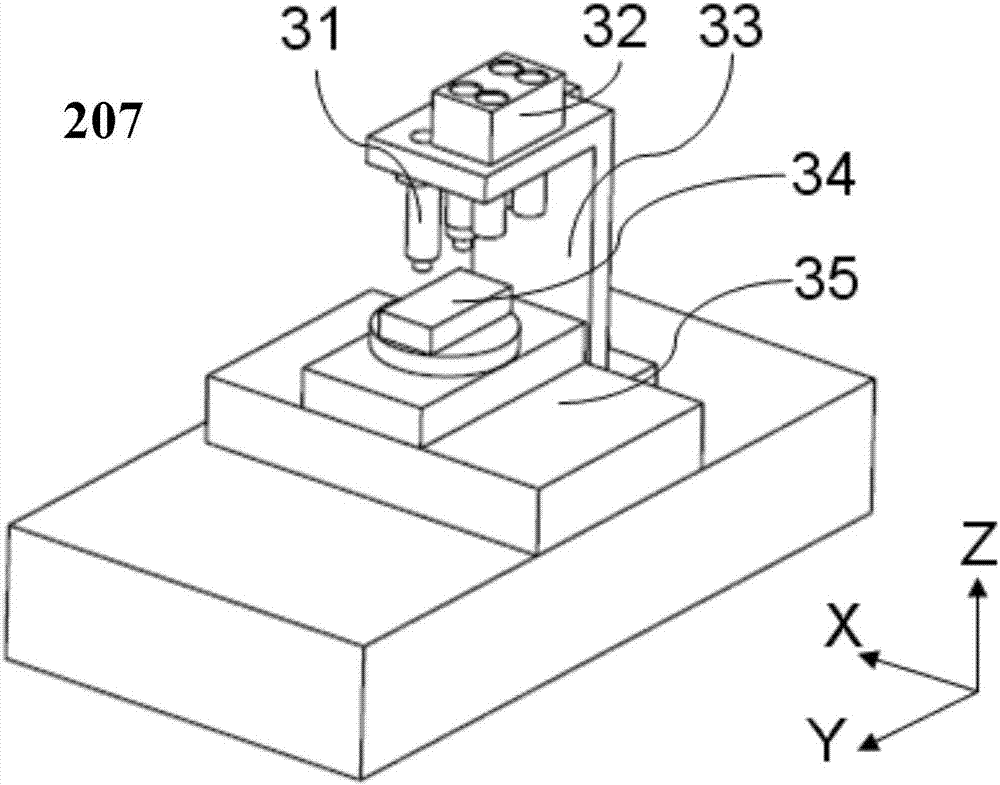

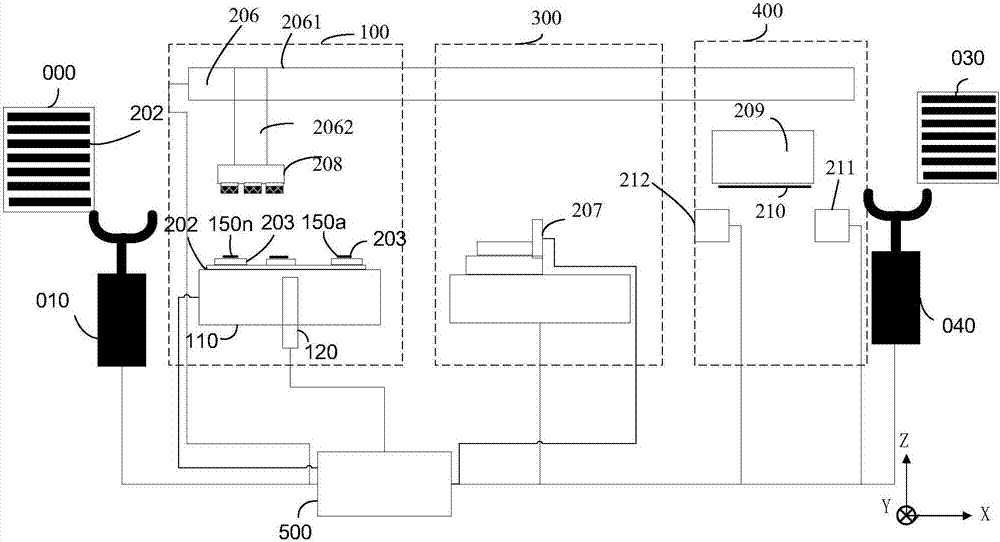

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that the drawings are all in a very simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0041] Such as image 3 As mentioned above, the structure of the chip bonding device involved in the embodiment of the present invention includes: the first moving table 110, the second moving table 206, the suction cup 208, the fine adjustment and transfer structure 207, the bonding table 209 and the control system 500;

[0042] The first moving platform 110 is used to carry and transport the chipset to a predetermined pick-up position;

[0043] The second moving table 206 is used to drive the suction cup 208...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com