Laser beam combination device

A laser processing device and laser technology, applied in the field of lasers, can solve problems such as inability to achieve high-power coupling output, and achieve the effect of avoiding differences and improving beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

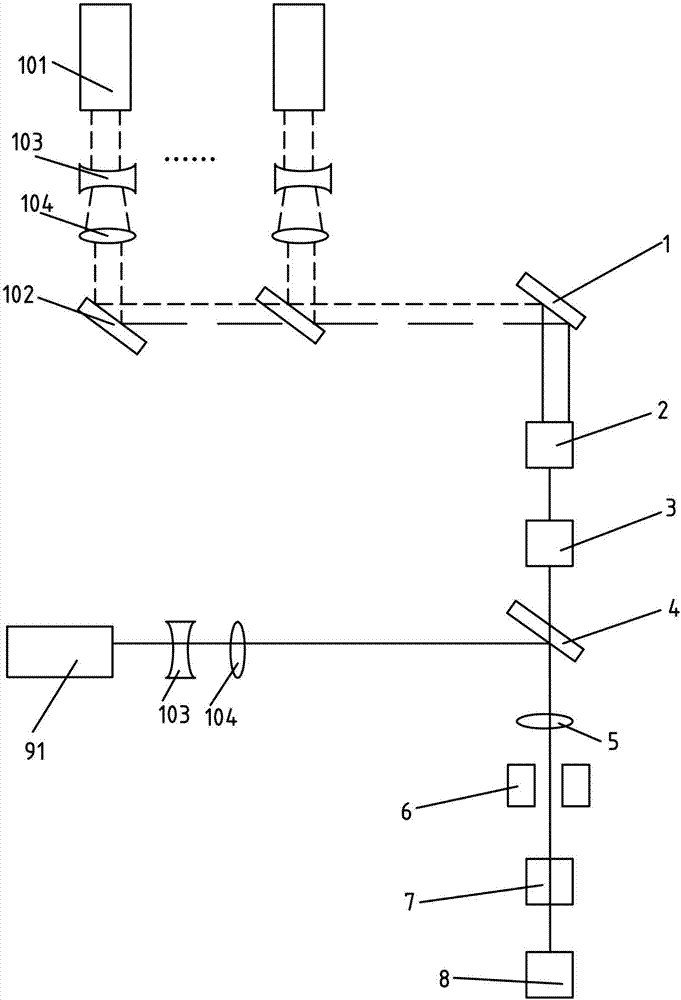

[0020] Such as figure 1 As shown, a laser beam combining device includes a main reflector 1, a first beam combining mirror 2, a first collimator 3, a dichroic mirror 4, an achromatic lens 5, an aperture 6, and a second beam combining Mirror 7, second collimator 8, first laser generating assembly and at least one second laser generating assembly; wherein,

[0021] The second laser generating component is used to emit a second laser and irradiate it on the main reflector 1, and the light reflected by the main reflector 1 enters the first beam combining mirror 2, then enters the first collimator 3, and then passes through the two-way Color mirror 4 transmits to form transmitted light;

[0022] The first laser generating component is used to emit the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com