Carbon fiber heating cable

A carbon fiber heating and cable technology, applied in the field of cables, can solve problems such as power attenuation, oxidation, and short service life, and achieve the effects of improving torsion resistance, ensuring safety, and zero cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

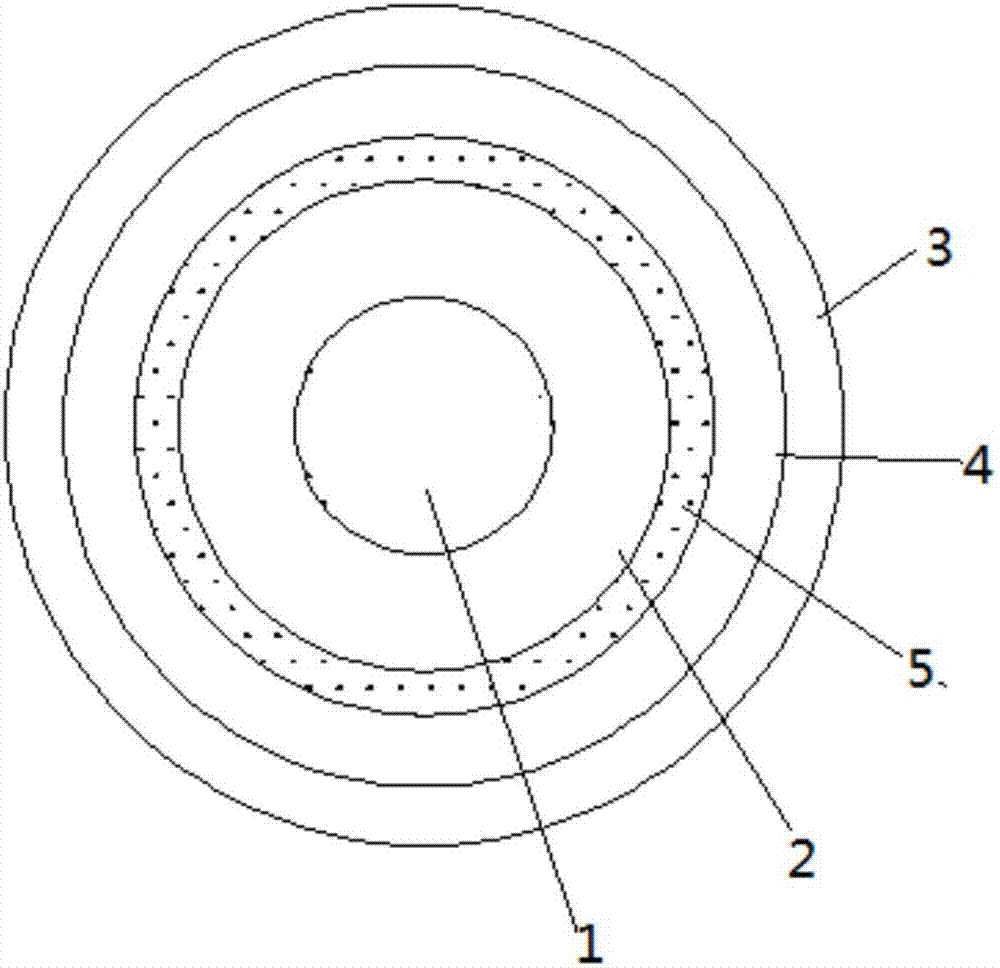

[0035] see figure 1 , a carbon fiber heating cable, characterized in that: it includes a carbon fiber heating conductor 1, the carbon fiber heating conductor is covered with an F46 insulating layer 2, and the F46 insulating layer is covered with a PVC sheath layer 3, and the F46 insulating layer and the A torsion-resistant cylinder 4 is arranged between the PVC sheath layers, and a polyester lining layer 5 is arranged on the inner wall of the torsion-resistant cylinder.

[0036] Described anti-torsion cylinder 4 is made of rubber rope weaving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com