Printed circuit board product with antenna structure and method for its production

A technology of printed circuit board and antenna structure, applied in the directions of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of long signal line, complex chip packaging and lamination, etc., and achieve the effect of depth and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

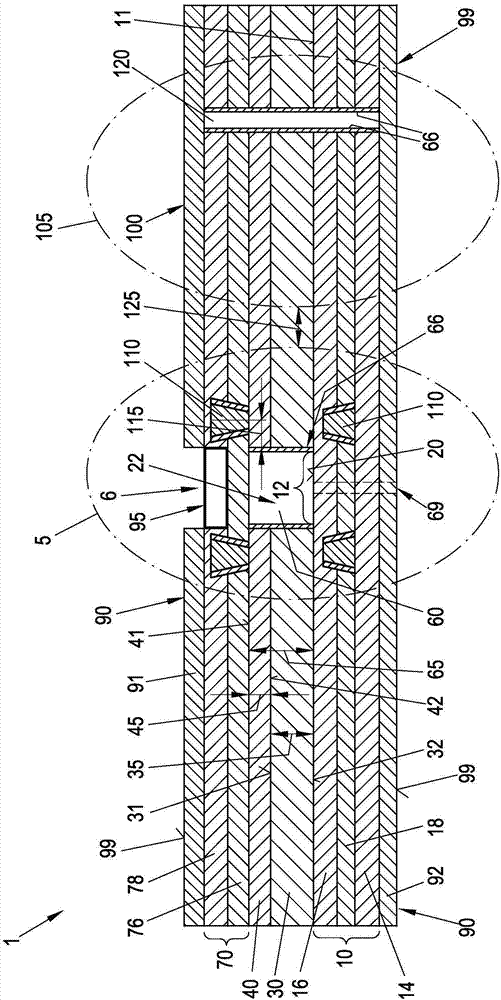

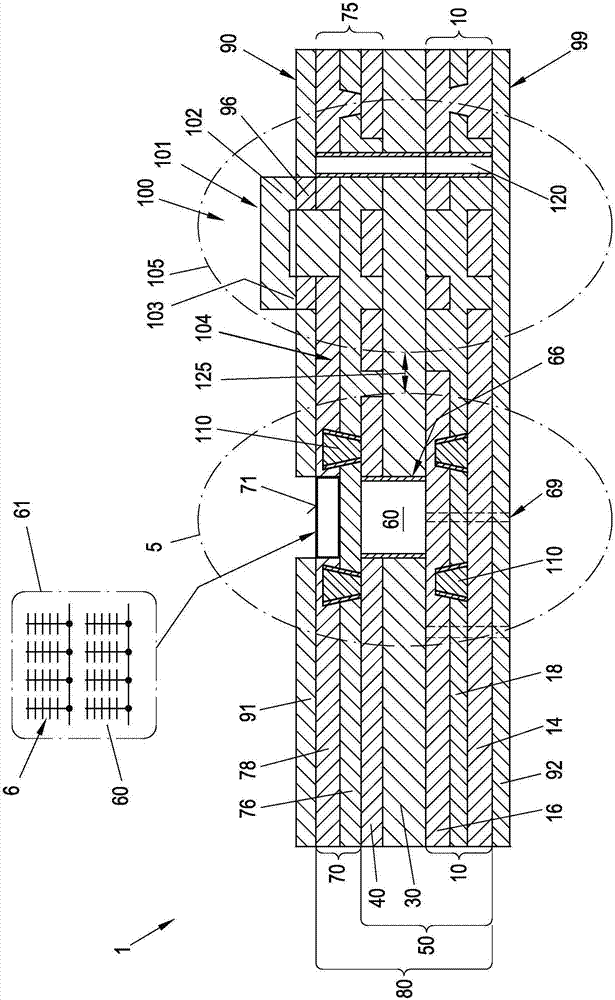

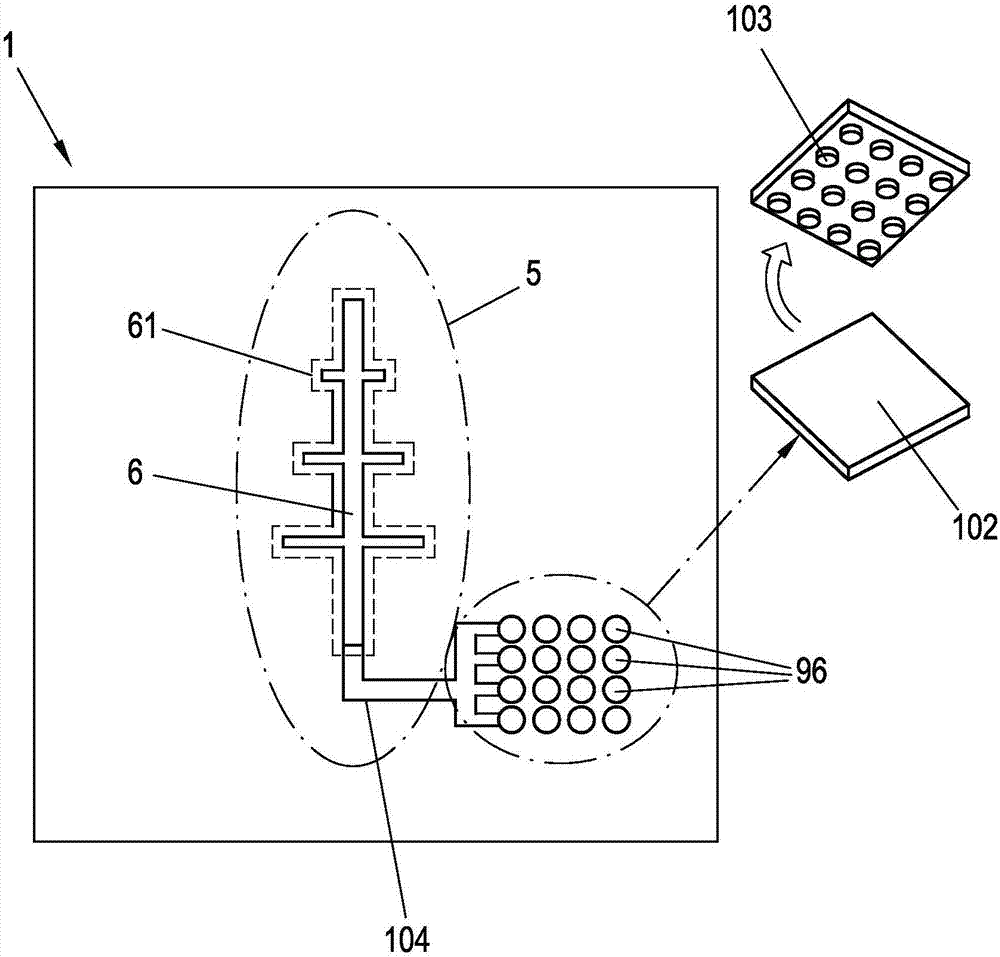

[0097] In the disclosed schematic diagrams, for ease of understanding, in addition to those diagrams that clearly show the conductive paths of the structured conductive layers connected by vias, the conductive layer is most often shown as a flat continuous conductive layer. Therefore, those drawings that schematically show continuous conductive layers without structured conductive paths and respective vias, micro-vias, plated through holes, etc., which connect the conductive layer, are not shown to be those skilled in the art. Known electrical functions. Those skilled in the art also know how to design and structure the conductive layer according to a specific task to obtain an appropriate conductive path. The main purpose of the drawings is to exemplify the corresponding layer structure in the production of an intermediate printed circuit board product according to the present invention in a schematic way. It is emphasized that the drawings are not shown to true scale, as for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com