Method for preparing raw Pu'er tea from tea raw materials growing at low altitude

A technology of raw Pu'er tea and low altitude, applied in the direction of tea treatment before extraction, can solve the problems of high price, insufficient market supply, rising tea prices, etc., to reduce production costs, expand raw material sources, and achieve good quality stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This example provides a method for preparing raw Pu-erh tea using low-altitude tea raw materials. The variety of tea raw materials used is Yinghong No. 9, and the experiment time is April 13-14, 2017. The specific method includes the following steps:

[0034] (1) Withering: using one bud, two leaves and three leaves of Yinghong No. 9 tea tree and opposite pod leaves of the same tenderness as fresh tea leaf raw materials, the fresh tea leaf raw materials are withered until the water content is 76.2%, and material A is obtained.

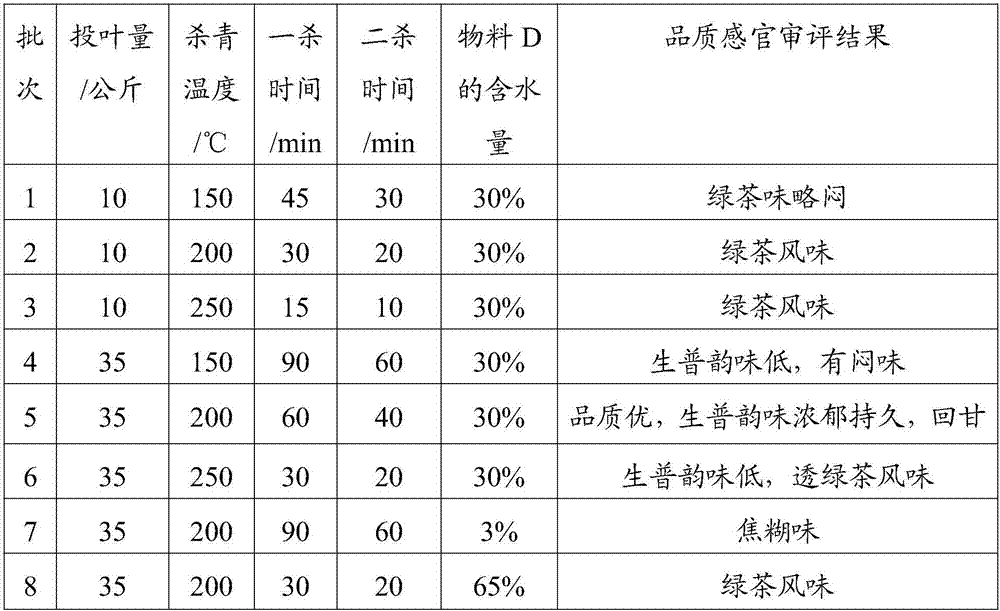

[0035] (2) The first greening: use 901 gas greening machine to carry out greening treatment on material A, adjust the number of revolutions of the greening machine to 3 rpm, the amount of leaves thrown is 10, 35 kg, and the temperature of greening is 150-250 °C, The killing time is 15-90 minutes, until the bud color pekoe is revealed and the leaves are slightly black, then the machine is removed to obtain the material B.

[0036] (3) The first s...

Embodiment 2

[0046] This example provides a method for preparing raw Pu-erh tea using low-altitude tea raw materials. The variety of tea raw materials used is Yinghong No. 9, and the experiment time is April 15-16, 2017. The specific method includes the following steps:

[0047] (1) withering: with embodiment 1.

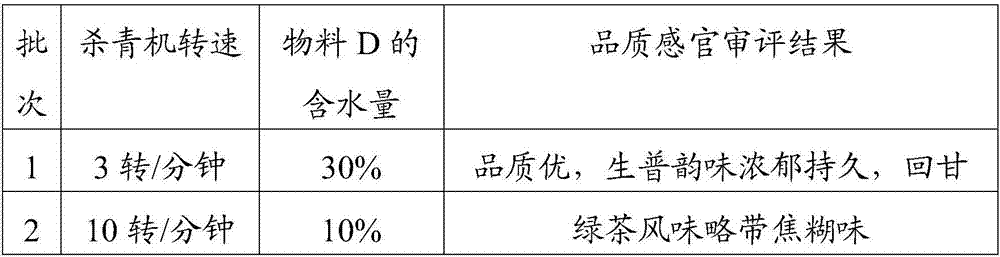

[0048] (2) First time greening: use 901 gas greening machine to carry out greening treatment on material A, adjust the number of revolutions of the greening machine to 3 rpm or 10 rpm, and the amount of leaves to be thrown is 35 kg each, that is, to the tea raw material Until it falls out automatically, the temperature for finishing is 200° C., the time for finishing is 60 minutes, and material B is obtained.

[0049] (3) pile for the first time: with embodiment 1.

[0050] (4) The second finishing: put all the material C into the 901 gas cleaning machine, carry out the finishing treatment on the material C, adjust the number of rotations of the cleaning machine to 3 rpm or 10 r...

Embodiment 3

[0058] This example provides a method for preparing raw Pu-erh tea using low-altitude tea raw materials. The variety of tea raw materials used is Yinghong No. 9, and the experiment time is April 15-16, 2017. The specific method includes the following steps:

[0059] (1) withering: with embodiment 1.

[0060] (2) Finishing: Adopt 901 gas-fired greening machine to carry out finishing process to material A, adjust the number of revolutions of the fixing machine to be 3 revolutions per minute, and the amount of leaf throwing is 35 kg, that is, until the tea raw materials fall out automatically, the temperature of finishing is 200°C, the time for finishing is 60 or 100 minutes, get off the machine, and obtain material B.

[0061] (3) Wheat heap: Pour material B into a cloth bag or square towel and wrap it in a pile for 30 minutes immediately after getting off the machine to obtain material C. The water content of material C is 58% and 30% respectively.

[0062] (4) Kneading: Pour ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com