Rice polishing device

A polishing device and rice technology, applied in grain finishing, grain processing, application and other directions, can solve the problems of inconvenient adjustment of the height of the polishing barrel, the structure is not stable enough, and the polishing is not uniform enough, so as to achieve a good polishing effect and save time and energy. , polishing uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

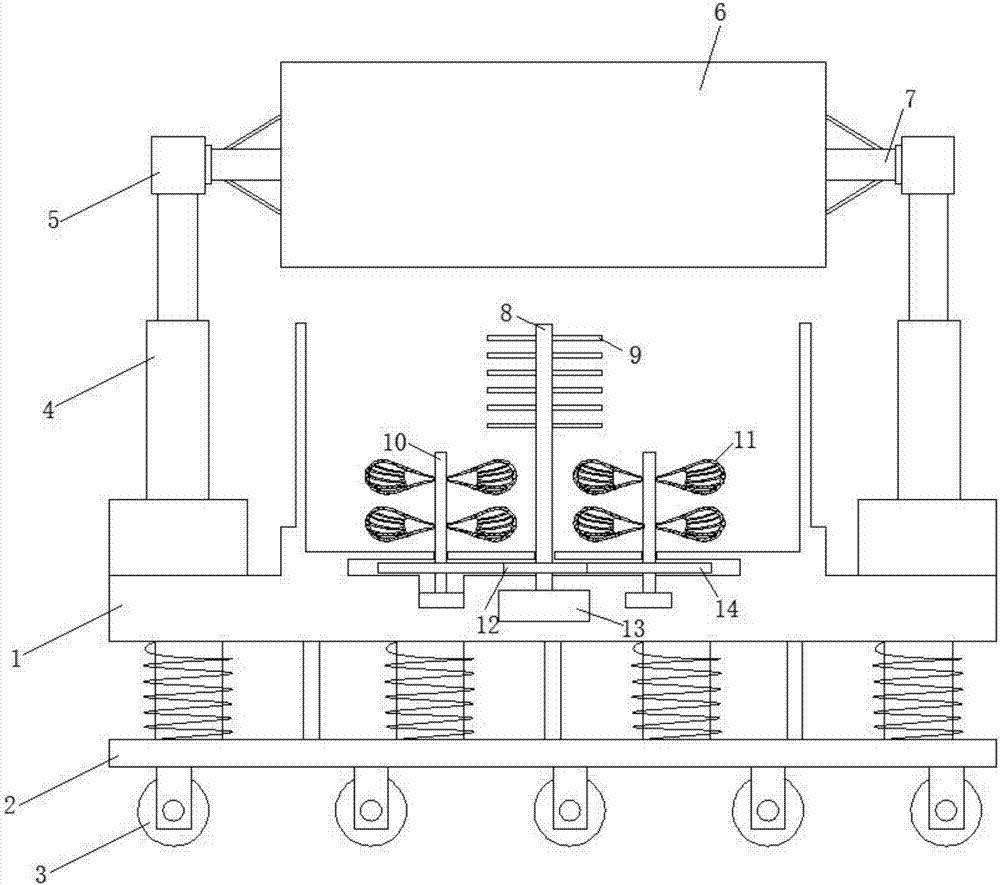

[0014] refer to figure 1 , a rice polishing device, comprising a base 1, the upper end of the base 1 is symmetrically provided with two drive motors, each drive motor is provided with an electric telescopic rod 4, and each electric telescopic rod 4 is provided with a first rotating motor 5. Connecting seats 7 are provided on opposite sides of the two first rotating motors 5, and a polishing barrel 6 is provided between the two connecting seats 7. The polishing barrel 6 is provided with an opening and a feeding cover, and the base 1 The upper end is provided with a loading bucket, the base 1 is provided with a second rotating motor 13, the second rotating motor 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com