Container structure used for storing liquid

A liquid and container technology, which is applied in the field of container structure for storing liquids, can solve the problems of container body extrusion deformation, production cost, high transportation and recycling cost, explosion, etc., to improve the pressure bearing capacity, improve the shelf life, and improve safety performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

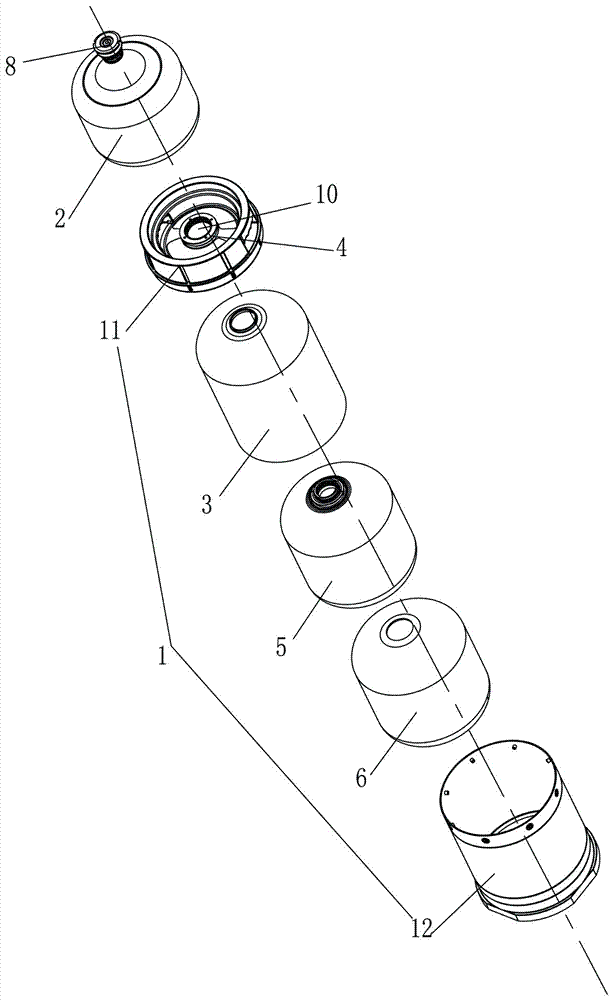

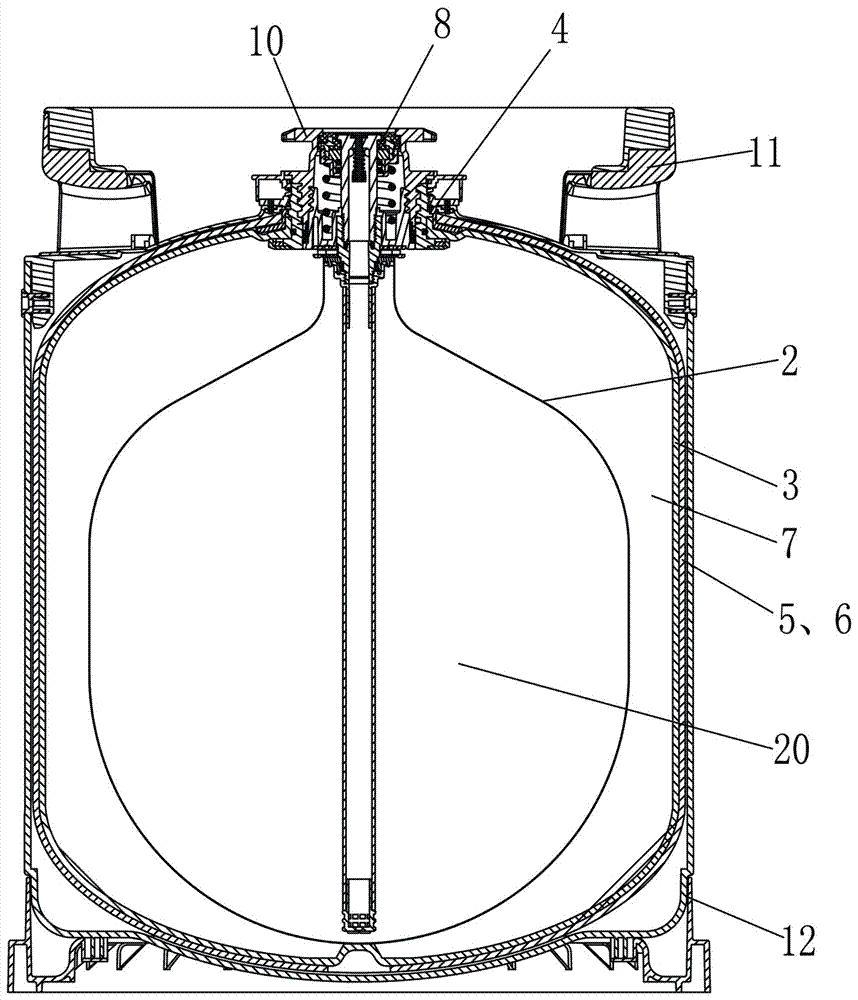

[0031] Specific implementation methods, such as figure 1 , figure 2 As shown, a container structure for storing liquid according to the present invention mainly includes the following components: container body 1, built-in barrier composite bag 2, inner container body 3, sealing member 4, silicon oxide film layer 5, glass fiber Layer 6 and switch valve 8;

[0032] In actual production and assembly, the container body 1 is a barrel-shaped structure (other shapes can also be used), which includes an upper cover 11 and a lower barrel body 12, and the lower barrel body 12 is blow-molded by HDPE; the inner barrier composite bag 2. It is made of a film composed of silicon oxide or other barrier materials, compounded with EVOH and nylon film. After forming, the on-off valve (that is, the wine spear 8) is heat-sealed and connected with the inner barrier composite bag 2; the inner container body 3 It is also blow molded by HDPE, and then the outer surface is covered with a layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com