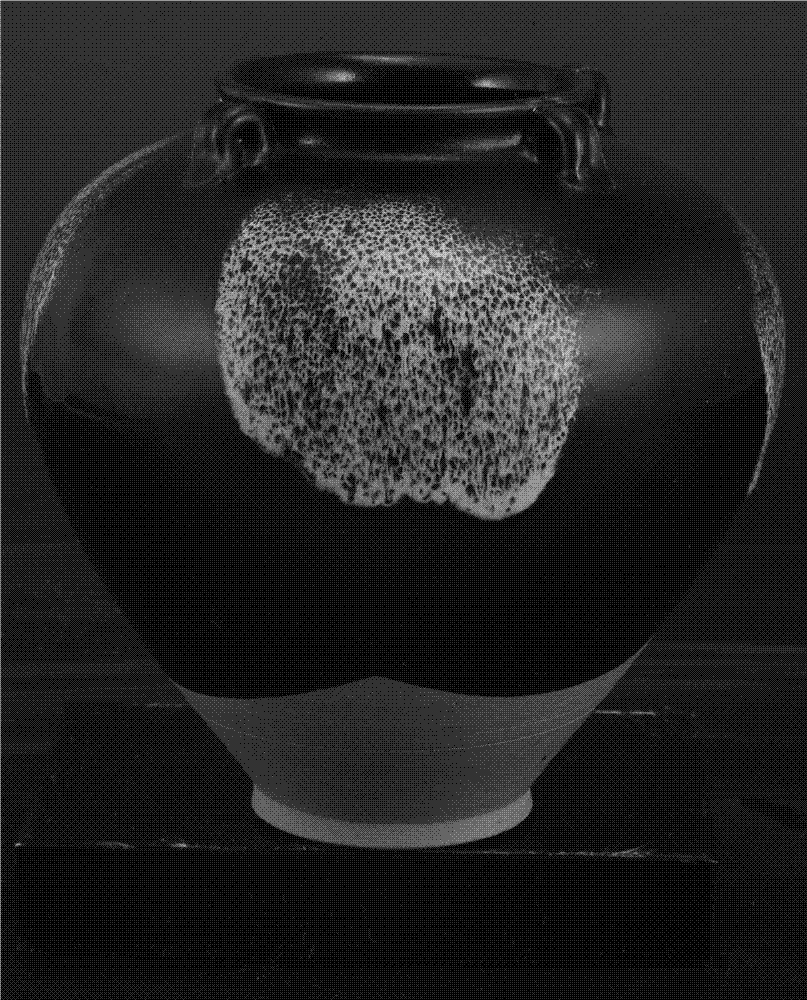

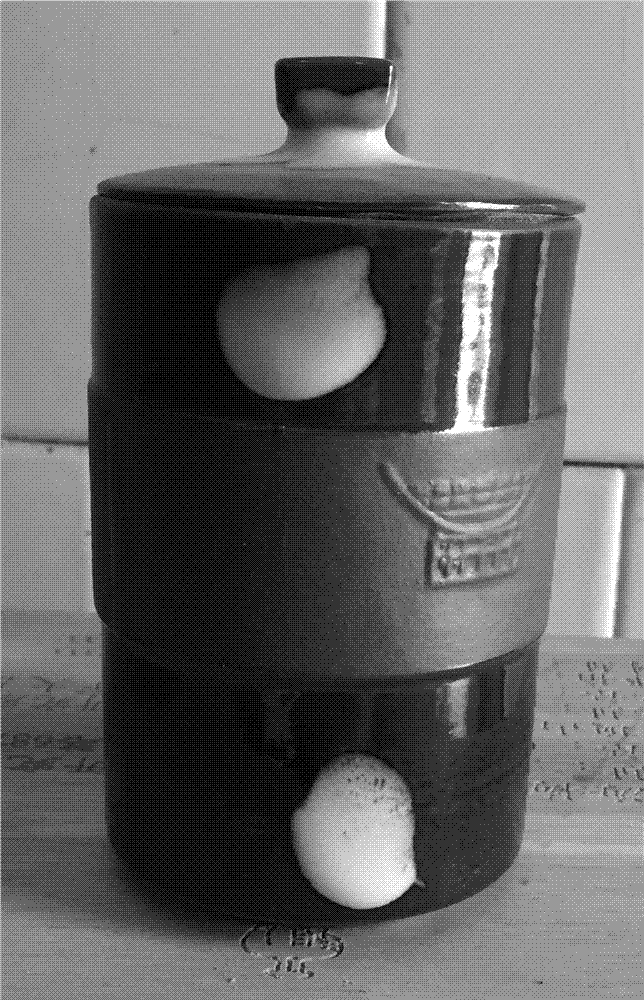

Brown-field milky-white blue-spot glaze and colored glaze porcelain prepared by utilizing brown-field milky-white blue-spot glaze

A blue spot glaze and milky white technology, applied in the field of ceramics, can solve the problems of lack of dynamic and three-dimensional sense, flat and single color spots, lack of fluidity, etc., to achieve strong three-dimensional color rendering, increase artistic effects, and liquid-liquid phase separation obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A brown-ground milky-white blue-spotted glaze, which is composed of a base glaze and a spotted glaze. The weight percentage of the base glaze is: clay 50%, feldspar 35%, and quartz 15%; the weight percentage of the glaze is: quartz 35% %, yellow feldspar 30%, calcite 20%, fluorite 4%, wood ash 3%, bone meal 2%, zinc oxide 6%;

[0041] The clay is produced in Lushan County and has been specially screened.

[0042] The bone powder is bovine bone powder, and has been calcined, the calcining temperature is 980° C., and the calcining time is 6 hours.

[0043] Described bottom glaze adopts following method to make:

[0044] a. Roll the raw materials feldspar and quartz respectively, and mix them after passing through a 60-mesh sieve;

[0045] b. Add water to the mixture and grind for 12 hours according to the weight ratio of material to water: 1:1.3;

[0046] c. Mix the clay with water at a weight ratio of 1:2.8, add water and let it stand for 9 hours, skim off the surface...

Embodiment 2

[0055] A brown-ground milky-white blue-spotted glaze, which is composed of a base glaze and a spotted glaze. The weight percentage of the base glaze is: clay 60%, feldspar 30%, and quartz 10%; the weight percentage of the glaze is composed of quartz 30% %, yellow feldspar 35%, calcite 15%, fluorite 6%, wood ash 4%, bone meal 3%, zinc oxide 7%.

[0056] Described clay is with embodiment 1.

[0057] The bone powder is bovine bone powder, which is calcined at a temperature of 1000° C. and for a time of 4 hours.

[0058] Described bottom glaze is made by following method:

[0059] a. Roll the raw materials feldspar and quartz respectively, and mix them after passing through a 40-mesh sieve;

[0060] b. Add water to the mixture and grind for 10 hours according to the weight ratio of material to water: 1:1.2;

[0061] c. Mix the clay with water at a weight ratio of 1:2.5, add water and let it stand for 8 hours, skim off the surface foam with a container, scoop out the middle laye...

Embodiment 3

[0070] A kind of milky white blue mottled glaze of brown ground, is made up of bottom glaze and mottled glaze, and the weight percent composition of described bottom glaze is the same as embodiment 1, and the composition of the weight percent of mottled glaze is: quartz 35%, yellow feldspar 28%, calcite 25% , 4% fluorite, 2% wood ash, 1% bone meal, 5% zinc oxide.

[0071] Described clay and bone powder are with embodiment 1.

[0072] Described bottom glaze is made by following method:

[0073] a. Roll the raw materials feldspar and quartz respectively, and mix them after passing through a 70-mesh sieve;

[0074] b. Add water to the mixture and grind for 14 hours according to the weight ratio of material to water: 1:1.4;

[0075] c. Mix the clay with water at a weight ratio of 1:3.0, add water and let it stand for 10 hours, skim off the surface foam with a container, scoop out the middle layer of material water for later use, and discard the bottom sediment;

[0076] d. Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com