High-dielectric constant epoxy resin composition and preparation method thereof

A technology of high dielectric constant and epoxy resin, which is applied in the preparation of the above-mentioned composition and the field of epoxy resin composition with high dielectric constant, can solve problems such as no clear solution, reduce warpage and reduce chip footprint Phenomenon, the effect of increasing the crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

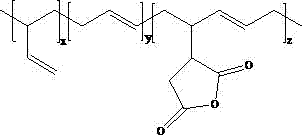

[0045] Embodiment 1, a kind of high dielectric constant epoxy resin composition: the main component of this epoxy resin composition includes: epoxy resin, curing agent, curing agent accelerator, high dielectric filler, stress absorber and fumed white carbon black; described epoxy resin is to contain the epoxy resin described in following formula (1):

[0046]

[0047] Formula 1)

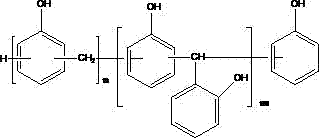

[0048] The curing agent is a phenolic resin, which contains the phenolic resin described in formula (3), wherein, m and n are integers of 1-15,

[0049]

[0050] Formula (3)

[0051] The weight of described epoxy resin accounts for 5% of epoxy resin composition gross weight;

[0052] The weight of described curing agent accounts for 10% of epoxy resin composition gross weight;

[0053] Described curing agent accelerator accounts for 0.05% of epoxy resin composition gross weight;

[0054] Then add other appropriate amount of commonly used additives.

Embodiment 2

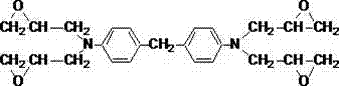

[0055] Embodiment 2, a kind of high dielectric constant epoxy resin composition: the main component of this epoxy resin composition includes: epoxy resin, curing agent, curing agent accelerator, high dielectric filler, stress absorber and fumed white carbon black; the epoxy resin contains the epoxy resin described in formula (1) and formula (2):

[0056] The curing agent is a phenolic resin, which contains the phenolic resin described in formula (3);

[0057] The weight of described epoxy resin accounts for 18% of epoxy resin composition gross weight;

[0058] The weight of described curing agent accounts for 10% of epoxy resin composition gross weight;

[0059] The curing agent accelerator accounts for 1% of the total weight of the epoxy resin composition.

Embodiment 3

[0060] Embodiment 3, a kind of high dielectric constant epoxy resin composition: the main components of this epoxy resin composition include: epoxy resin, curing agent, curing agent accelerator, high dielectric filler, stress absorber and fumed white carbon black; described epoxy resin is to contain the epoxy resin described in following formula (1) and formula (2):

[0061] The curing agent is a phenolic resin, which contains the phenolic resin described in formula (3);

[0062] The weight of described epoxy resin accounts for 15% of epoxy resin composition gross weight;

[0063] The weight of described curing agent accounts for 5% of epoxy resin composition gross weight;

[0064] Described curing agent accelerator accounts for 1.5% of epoxy resin composition gross weight;

[0065] The high dielectric filler is selected from alumina or titanate; the titanate is preferably one or more of barium titanate, calcium titanate, strontium titanate or other ferroelectric ceramic mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com