A preparation method of high-precision and extremely small-sized self-supporting beryllium thin film

A high-precision, beryllium-supporting technology, which is applied in vacuum evaporation plating, coating, sputtering plating, etc. Support the problem of low applicability of beryllium film, and achieve the effect of regular shape, high quality and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] A method for preparing a self-supporting beryllium thin film with high precision and extremely small size, comprising the following steps in sequence:

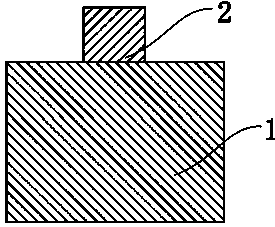

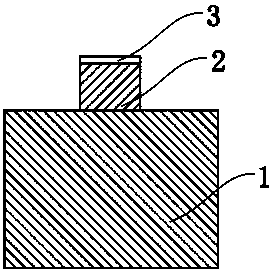

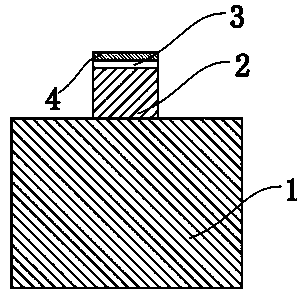

[0031] Step 1: Precision CNC machining of high-precision steps on the surface of the copper block

[0032] In this embodiment, a pure copper block of 10mm×10mm×10mm is used as the substrate (the inventor has proved through experiments that the present invention can be realized in any size of 10mm×10mm×10mm~15mm×15mm×15mm), and an appropriate clamping method, Cutting tool and chip parameters, etc., are milled in layers on the surface of the copper block to produce high-precision steps with a step height of 1mm~2mm. Due to the high precision of the CNC machining method, generally up to 1 μm, the shape (circular or square) of the steps can be precisely controlled to a certain value between tens of μm and hundreds of μm by using this processing method. The outer dimension of the step is the outer dimension of the high-prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com