High-pressure injection grouting expanded-base inlaid-type pile and preparation method

A high-pressure injection and embedded technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of complex process, low strength and high construction cost, achieve high mechanical strength, reduce construction cost, and reduce soil disturbance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

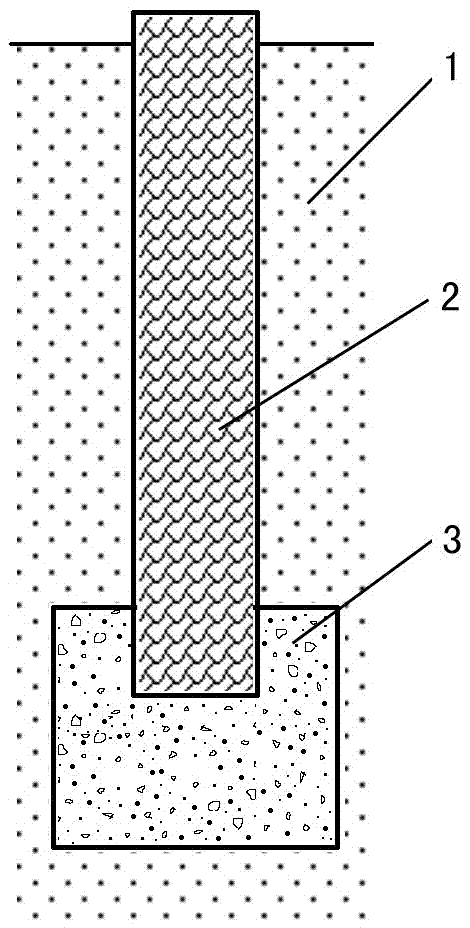

[0012] refer to figure 1 The upper section of the pile body 2 can adopt any kind of pile body, such as concrete pouring pile, reinforced cage concrete pouring pile, prefabricated pile, prefabricated pipe pile and steel pipe pile, and the lower section of the pile body is a high-pressure jet grouting expansion pile. Bottom pile 3, the lower end of the upper pile body 2 is embedded in a larger diameter high-pressure jet grouting bottom expansion pile 3, the diameter of the high-pressure jet grouting bottom expansion pile 3 is more than 1.5 times the diameter of the upper pile body 2, and the upper pile The embedding depth of the lower end of the body 2 in the high-pressure jet grouting bottom expansion pile 3 is 0.1 to 10 times the diameter of the upper pile body 2 .

[0013] The construction method of the pile body is as follows: first, the high-pressure jet grouting method is used to drill holes to reach the designed bottom expansion pile depth, and the pressure parameters of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com