Structure-integrated heat-insulation and decorating exterior formwork and exterior wall constructing method thereof

An external formwork and integrated technology, which is applied in the direction of formwork/formwork components, walls, building components, etc., can solve the problems of heavy on-site construction workload, reduced construction strength, and blocked construction of decorative layers, so as to improve construction efficiency and construction quality , Improving the convenience of construction and the effect of reasonable overall structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

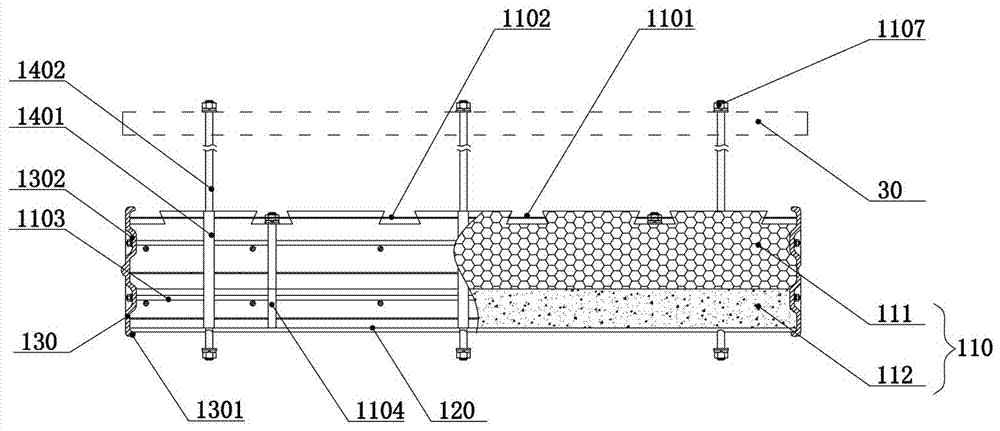

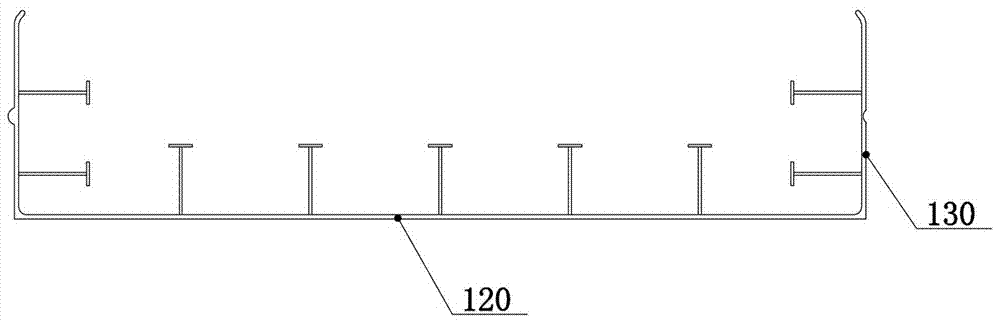

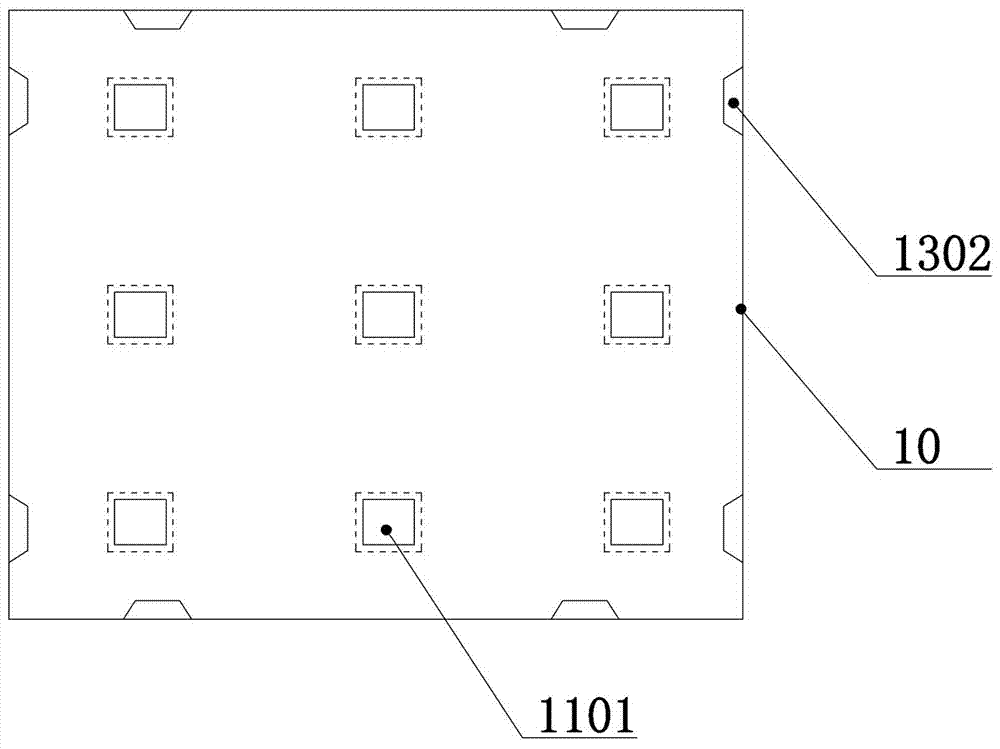

[0041] A structure-integrated thermal insulation and decorative outer formwork of the present invention includes a thermal insulation structure layer 110, a decorative structure layer 120, and a lateral connecting plate 130, wherein the inner surface of the thermal insulation structure layer 110 is used as the outer formwork surface when the concrete structure is poured, and is connected with the concrete At least one anchor groove or / and at least one anchor hole 1101 is arranged on the inner side of the thermal insulation structure layer 110 corresponding to the structure 20, and a steel mesh sheet 1102 is pre-embedded in the thermal insulation structure layer 110, and the anchor groove or / and the described A part of the steel mesh 1102 is perforated in the anchor holes 1101. During the concrete pouring process, the concrete can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com