Intelligent tube push bench cutterhead

A technology of pipe jacking and machine tool, used in mining equipment, earth-moving, tunnels, etc., can solve the problems of tool damage, maximum drilling depth, whether difficult tools can be reached, etc., to prevent tool damage, easy peeling and excavation. , Guarantee the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

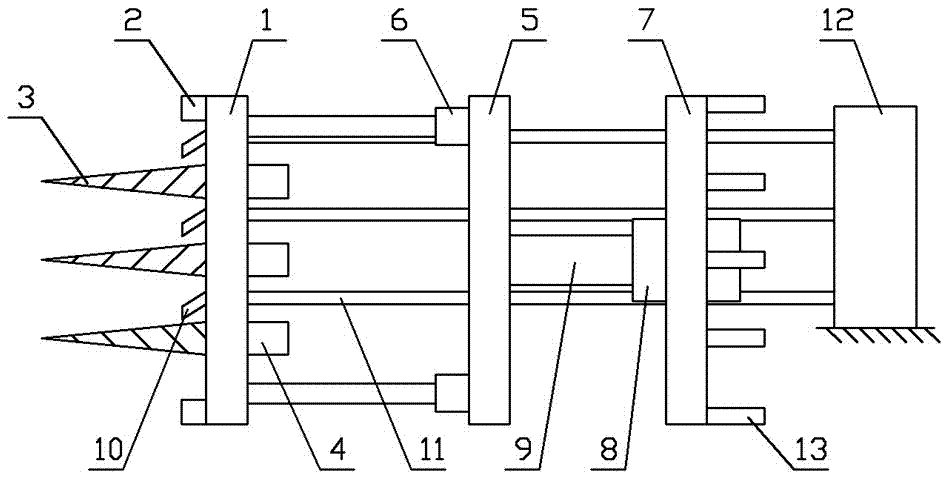

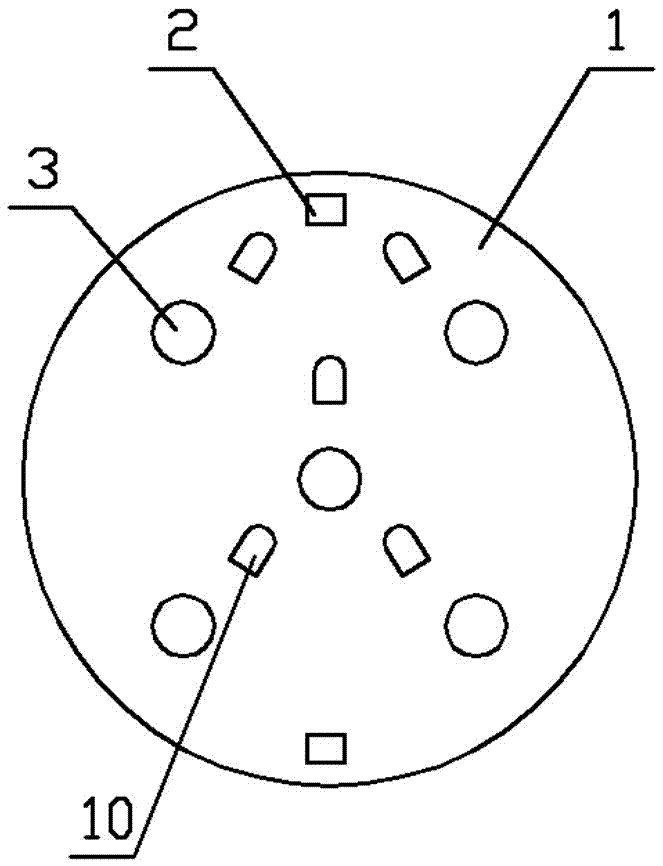

[0025] Such as figure 1 and figure 2 As shown, it includes a jacking disc 1, a central controller and an alarm; the jacking disc 1 is circular; along the jacking direction, a pressure sensor 2 and evenly distributed drill bits 3 are arranged on the front end of the jacking disc 1, and the jacking disc 1 The first motor 4 is fixed on the rear end surface of the tray 1, and the drill 3 is connected to the power output shaft of the first motor 4; the central axis of the drill 3 is placed horizontally; the pressure sensor 2, the first motor 4, and the alarm are connected to the central The controllers are connected by electrical signals.

[0026] Along the jacking direction, a circular positioning plate 5 is provided behind the jacking plate 1; the positioning plate 5 is the same size as the jacking plate 1, and the center of the circle is aligned; the front end of the positioning plate 5 is provided with a horizontal electro-hydraulic rod 6, The top of the rod 6 is fixedly con...

Embodiment 2

[0032] Such as figure 1 and figure 2 As shown, it includes a jacking disc 1, a central controller and an alarm; the jacking disc 1 is circular; along the jacking direction, a pressure sensor 2 and evenly distributed drill bits 3 are arranged on the front end of the jacking disc 1, and the jacking disc 1 The first motor 4 is fixed on the rear end surface of the tray 1, and the drill 3 is connected to the power output shaft of the first motor 4; the central axis of the drill 3 is placed horizontally; the pressure sensor 2, the first motor 4, and the alarm are connected to the central The controllers are connected by electrical signals.

[0033] Along the jacking direction, a circular positioning plate 5 is provided behind the jacking plate 1; the positioning plate 5 is the same size as the jacking plate 1, and the center of the circle is aligned; the front end of the positioning plate 5 is provided with a horizontal electro-hydraulic rod 6, The top of the rod 6 is fixedly con...

Embodiment 3

[0038] Such as figure 1 and figure 2 As shown, it includes a jacking disc 1, a central controller and an alarm; the jacking disc 1 is circular; along the jacking direction, a pressure sensor 2 and evenly distributed drill bits 3 are arranged on the front end of the jacking disc 1, and the jacking disc 1 The first motor 4 is fixed on the rear end surface of the tray 1, and the drill 3 is connected to the power output shaft of the first motor 4; the central axis of the drill 3 is placed horizontally; the pressure sensor 2, the first motor 4, and the alarm are connected to the central The controllers are connected by electrical signals.

[0039] Along the jacking direction, a circular positioning plate 5 is provided behind the jacking plate 1; the positioning plate 5 is the same size as the jacking plate 1, and the center of the circle is aligned; the front end of the positioning plate 5 is provided with a horizontal electro-hydraulic rod 6, The top of the rod 6 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com