Blower fan filter set and EFU surface wind speed uniformity automatic testing device and method

A technology of automatic test device and filter, applied in the direction of measurement device, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve the problems of not realizing mechanical automation, airflow interference, reducing measurement efficiency, etc., and achieve mechanization and automation. , The probe position is precisely fixed, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

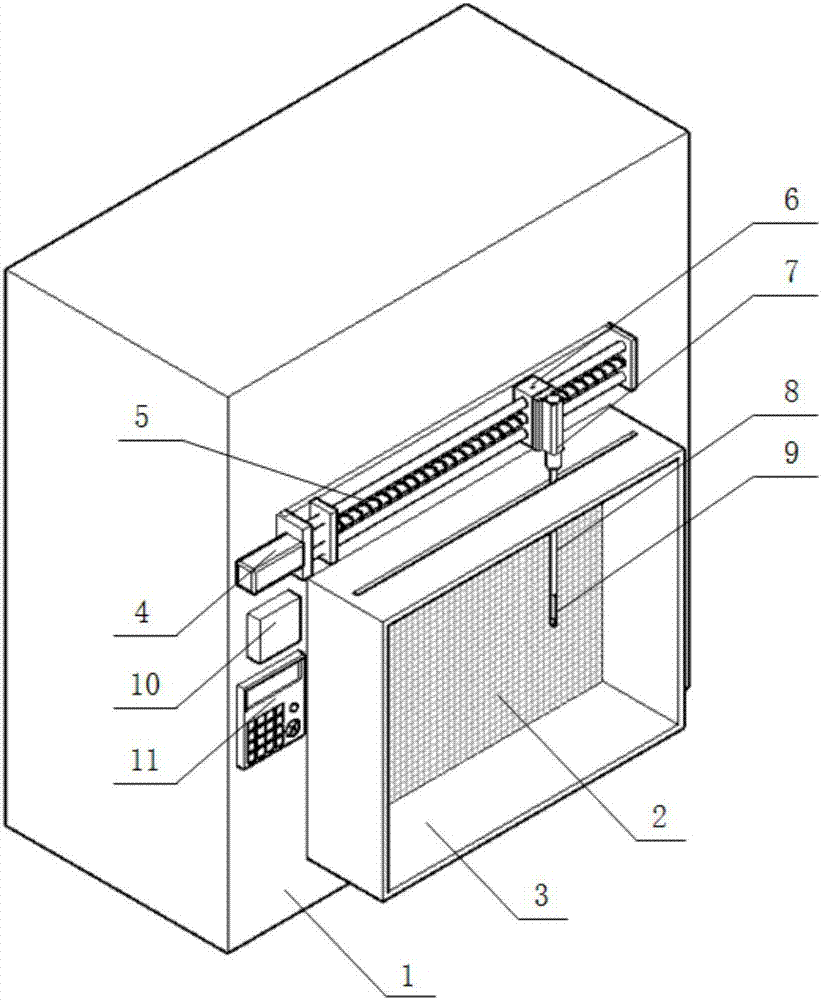

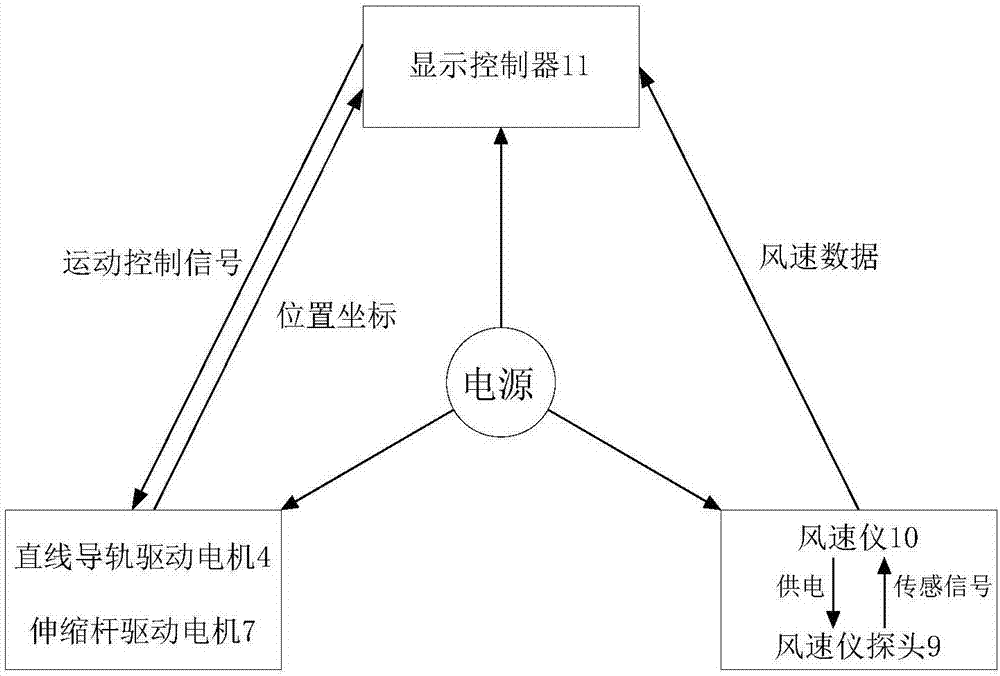

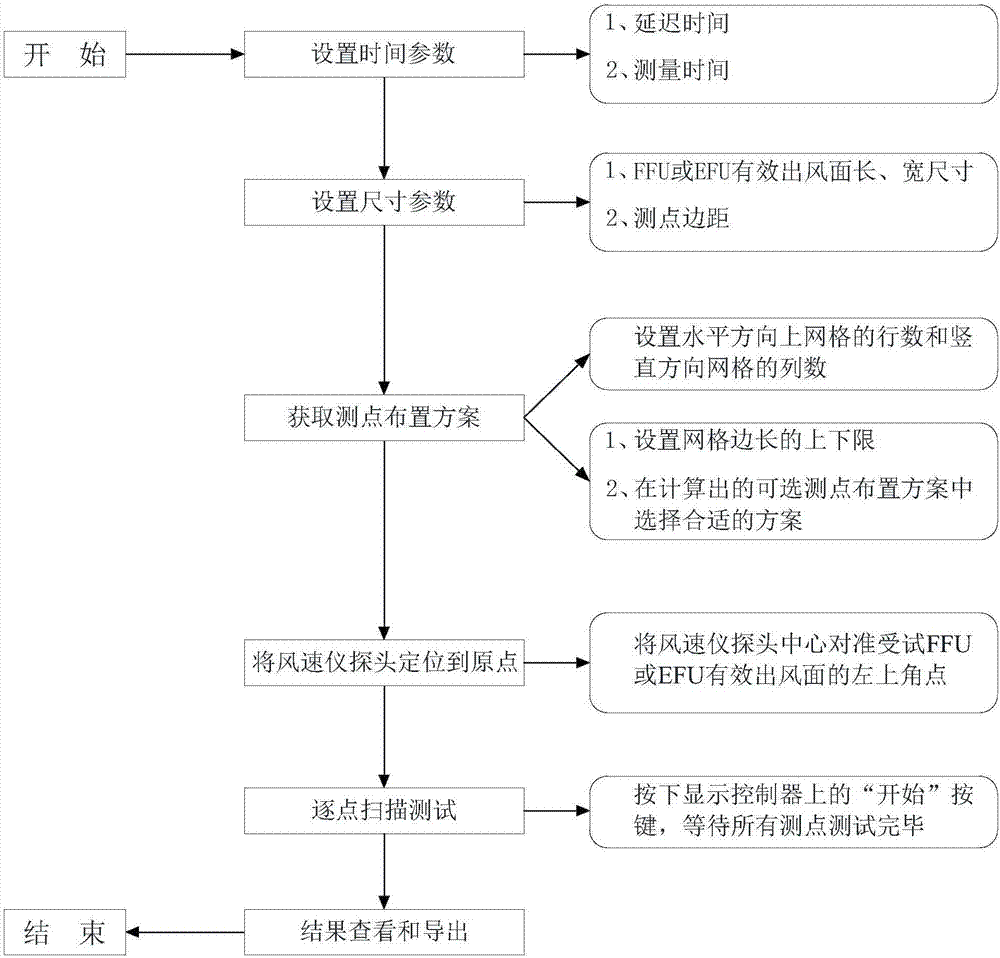

[0050] An automatic testing device for the surface wind speed uniformity of the fan filter unit and the equipment filter unit, the structure of which is as follows: figure 1 As shown, it includes a large static pressure box 1, a baffle 3, a linear guide rail mechanism, a telescopic rod mechanism, an anemometer probe 9, an anemometer 10 and a display controller 11.

[0051] The large plenum 1 is used to connect the auxiliary air system, install the FFU or EFU under test and deploy other components of the test facility. One side of the plenum box 1 is connected to the auxiliary air system, and the other side has an opening 2. The FFU or EFU under test is installed vertically in the plenum box 1, and the air is discharged from the opening 2 of the plenum box. When the size of the air outlet surface of the tested FFU or EFU is smaller than the size of the opening 2 of the plenum box, use the auxiliary plate for installation. In this example, the external dimensions of the tested ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com