Device for alignment of infrared lens set under low temperature

A lens group and centering device technology, which is applied in installation, instrumentation, optics, etc., can solve the problems of high processing and preparation costs, high subsequent inspection and assembly and preparation costs, extremely high processing precision requirements, and inability to achieve lens group centering operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

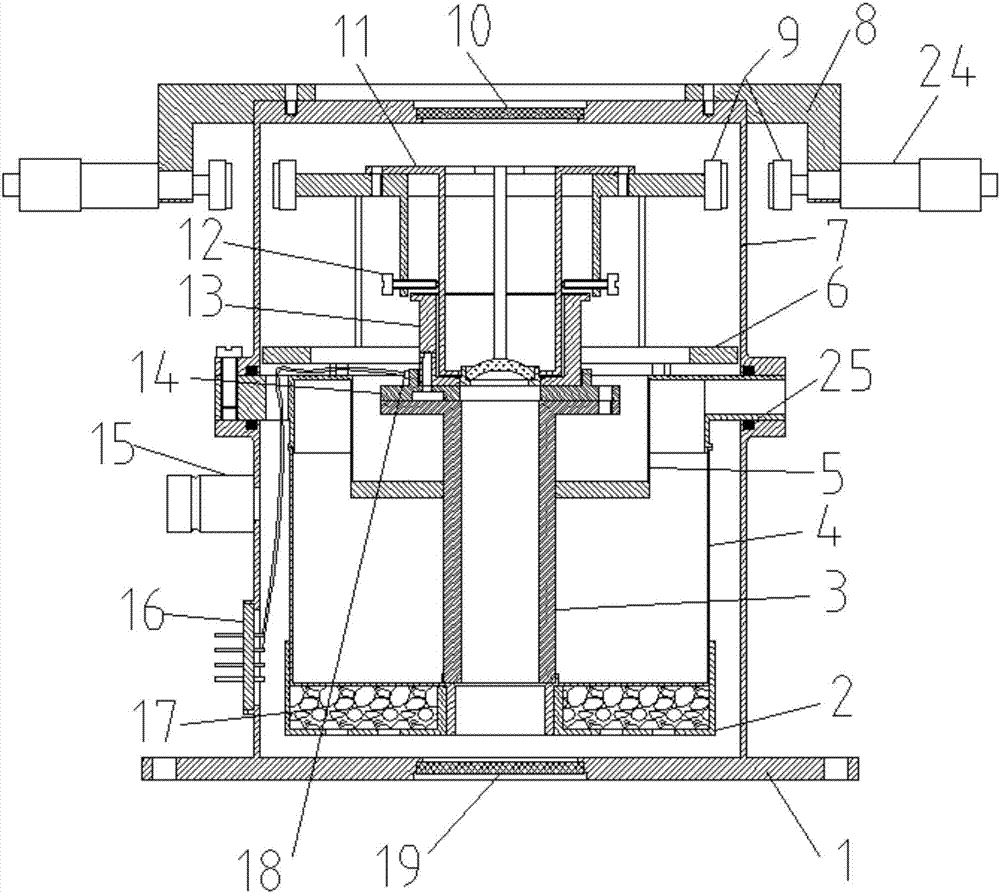

[0066] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings:

[0067] An example is the alignment and calibration of the lens group in a long-wave infrared detector assembly project. The lens group is integrated inside the detector assembly Dewar, and the operating temperature is 80K.

[0068] 1. The method for the preparation of each part in the present invention:

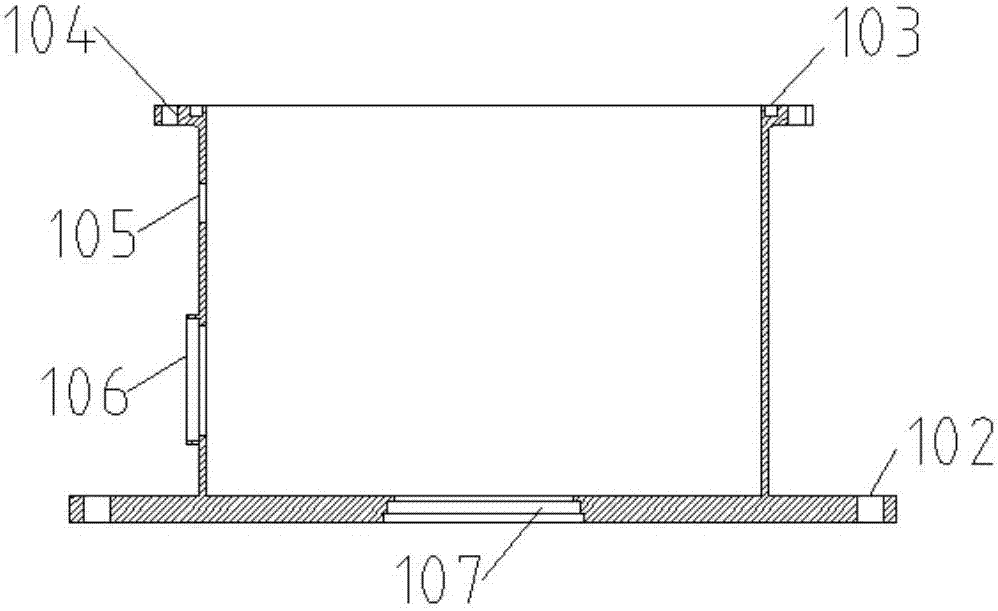

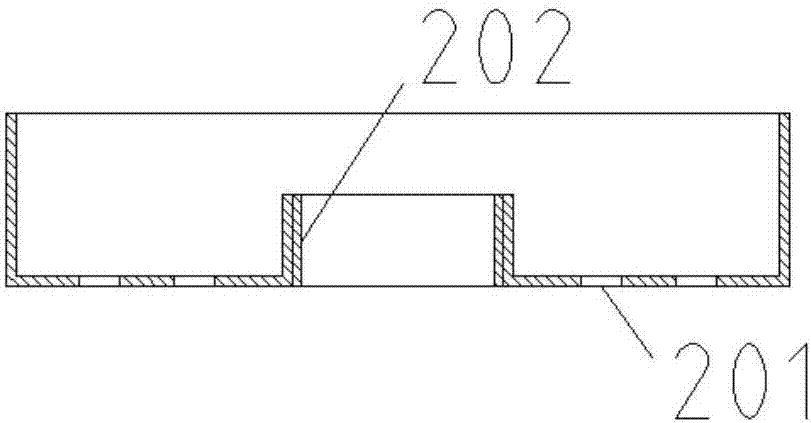

[0069] The material of the casing base 1 is stainless steel, the thickness of the barrel wall is 2mm, the height is 65mm, 8 fixing holes 102 with a diameter of 4.5mm are evenly distributed on the outer side of the bottom, and there is a base sealing ring groove 103 on the upper part, the groove width is 2mm, and the groove The depth is 1mm, the base mounting holes 104 are evenly distributed with 8 light holes with a diameter of 4.5mm in the circumferential direction, there are air extraction interface mounting holes 105 and lead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com