Pipe rack type cage-shaped large-sized anti-flow wind and wave resisting aquaculture net cage

A cage-like anti-wind and wave technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of high cost, inconvenient management, and no successful cases, etc., to achieve increased strength and anti-wind and wave ability, convenient assembly, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

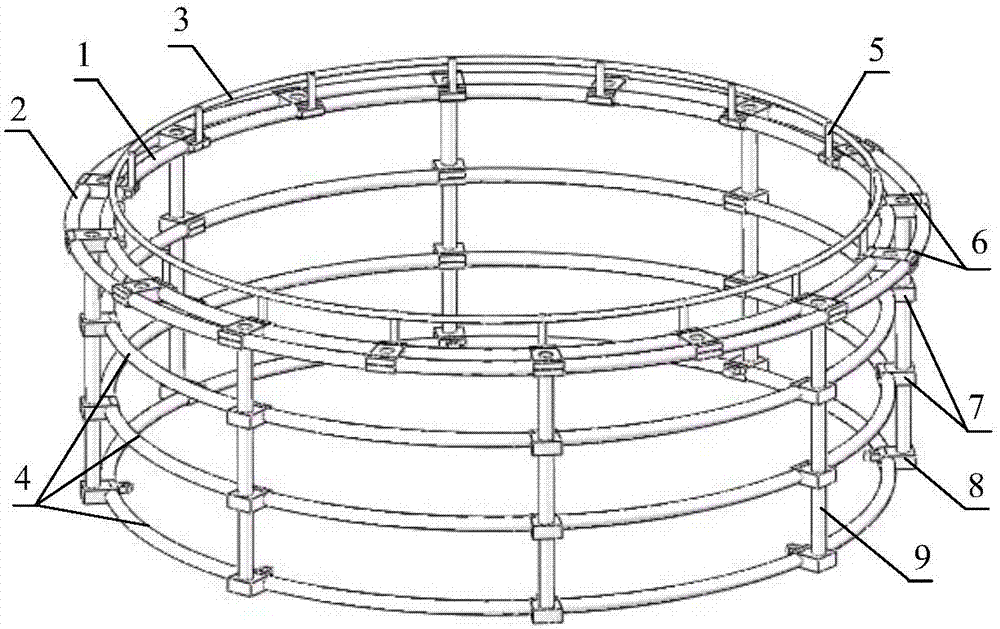

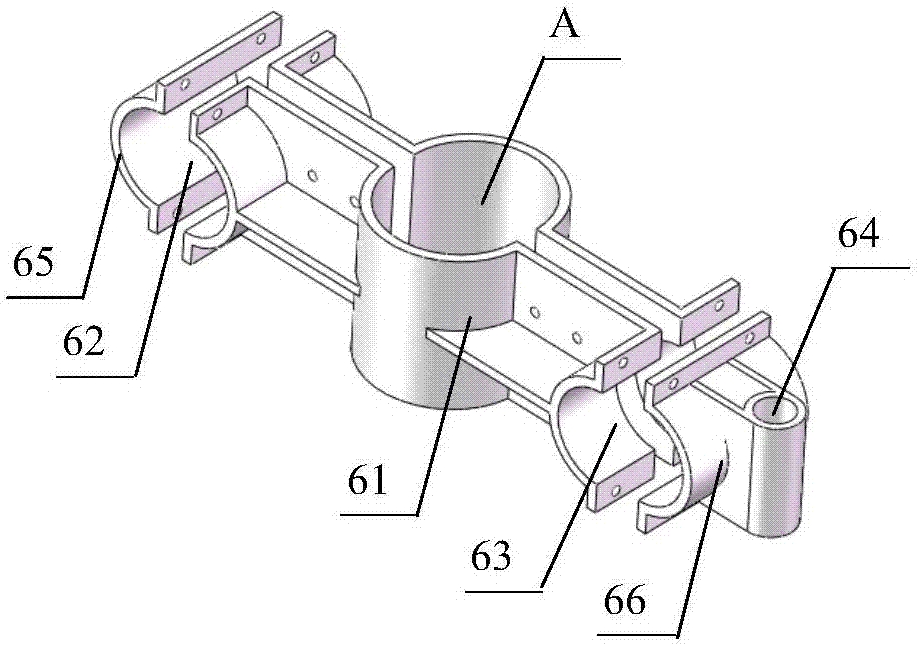

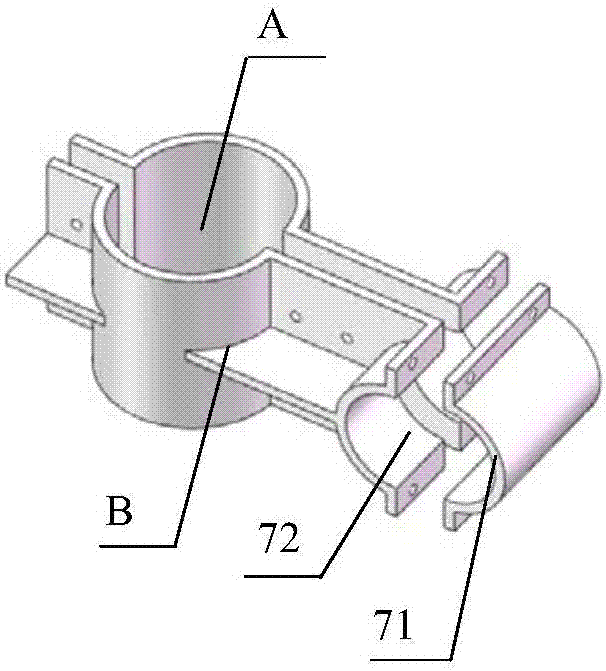

[0034] Such as Figure 1-5, a pipe-frame cage-shaped large-scale anti-wind and wave aquaculture net cage of the present invention includes a water surface floating frame composed of an inner floating pipe 1, an outer floating pipe 2 and a floating pipe connector 6, and a water frame composed of a handrail pipe 3 and a column 4 , an underwater frame formed by horizontal support pipe 4, middle connector 7, bottom connector 8 and vertical pipe 9, and the above three parts form a rigid cage-like rigid cage frame. It specifically includes: the inner floating tube ring welded by multi-section arc-shaped inner floating tube 1, the outer floating tube ring welded by multi-section arc-shaped outer floating tube 2, and multiple multi-section arc-shaped horizontal tubes. The horizontal support pipe ring and multiple vertical pipes 9 welded by the support pipe 4, wherein the outer side of the horizontal support pipe ring at the lowest level is installed with a plurality of bottom connecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com