Foundation premix with color changing from shallow to deep, foundation composition and preparation method thereof

The technology of premix and composition is applied in the directions of skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc. The production process is simple and controllable, the colors are rich and varied, and the production process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] The surface treatment of embodiment 1 titanium dioxide

Embodiment 1a

[0088] Example 1a Surface treatment of titanium dioxide using triethoxymethylsilane as the first siloxane surface treatment agent

[0089] Mix 0.45 kg of triethoxymethylsilane (ie, n1=2, a1=1 in formula (A)) and 1.05 kg of ethanol (95%) to prepare the first surface treatment solution. Ready to use.

[0090] Add 15kg of titanium dioxide into the mixer, and under stirring, spray the pre-prepared first surface treatment solution into the mixer and stir thoroughly, so that the first surface reaction solution and titanium dioxide are evenly mixed to obtain the first powder.

[0091] The first powder was discharged, immediately put into an oven, baked at 105° C. for 4 hours, cooled naturally and discharged.

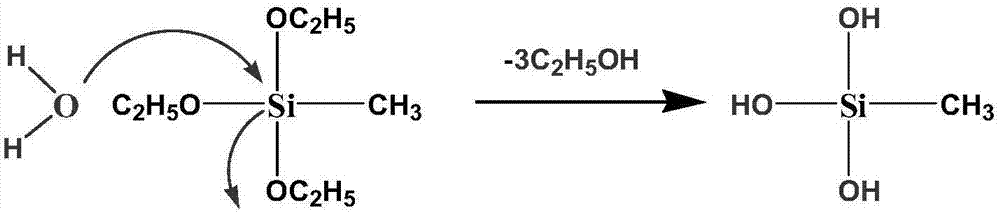

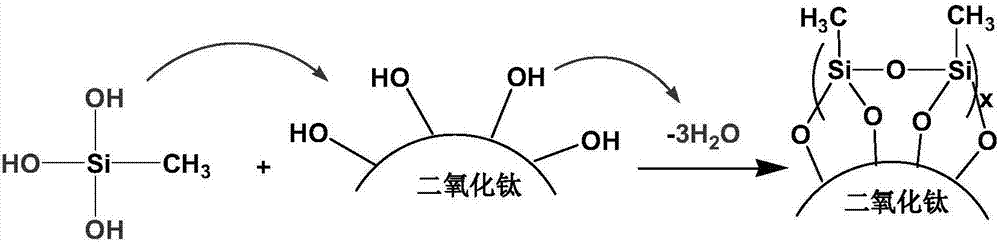

[0092] The reaction process comprises the steps: (1) triethoxymethylsilane hydrolysis see Figure 2A and (2) hydroxyl condensation dehydration see Figure 2B . After treatment, the surface properties of the obtained titania powders can be found in Figure 2C . After treat...

Embodiment 1c

[0096] Embodiment 1c uses polymethylsiloxane (n) shown in formula (C) 3 =25) Surface treatment of titanium dioxide as the first siloxane surface treatment agent

[0097] The titanium dioxide of 15kg is added stirrer, under stirring, the polymethylsiloxane (n) shown in the formula (C) of 0.45kg 3 =25) Spray into a blender and stir well, so that the polymethylsiloxane and titanium dioxide are evenly mixed to obtain the first powder.

[0098] The first powder was discharged, immediately put into an oven, baked at 105° C. for 4 hours, cooled naturally and discharged.

[0099] The reaction process is as follows Figure 3A shown. The surface chemical properties of titanium dioxide powder after treatment are as follows: Figure 3B shown. After treatment by this method, the surface of titanium dioxide powder is covered with Si-O linear chain and -CH 3 The two groups of branched chains are evenly wrapped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com