Corrosion pretreatment flotation method for low-grade refractory ilmenite

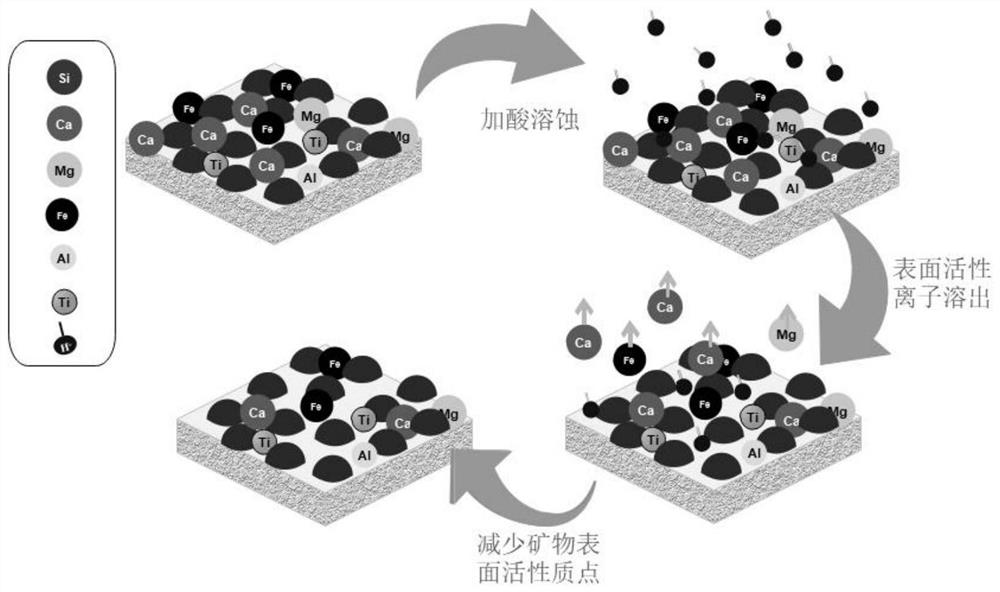

A low-grade ilmenite technology, applied in the flotation field of low-grade refractory ilmenite dissolution pretreatment, can solve the difficulty of dissociation of ilmenite monomer, reduce the selection of collectors, and make the separation effect worse To achieve the effect of reducing the amount of collector, solving the difficulty of flotation separation, and expanding the difference in properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A low-grade refractory ilmenite dissolution pretreatment flotation method, comprising the following steps:

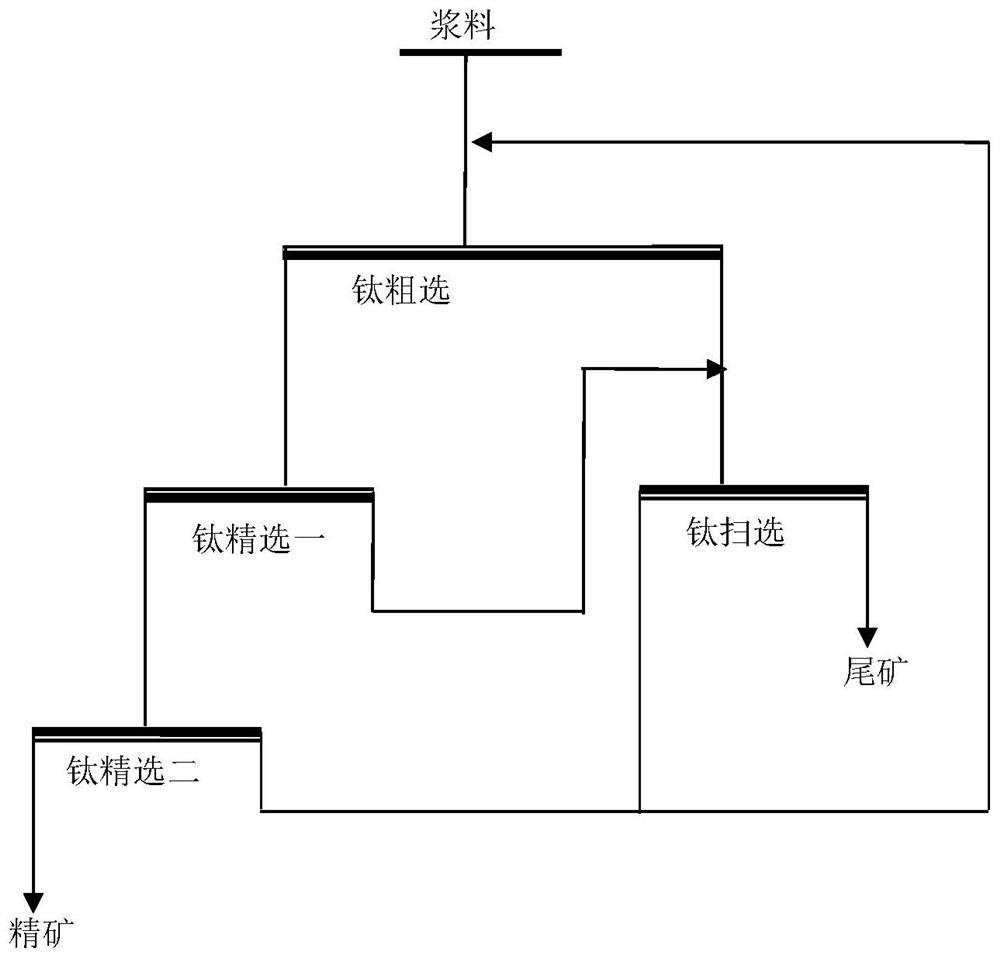

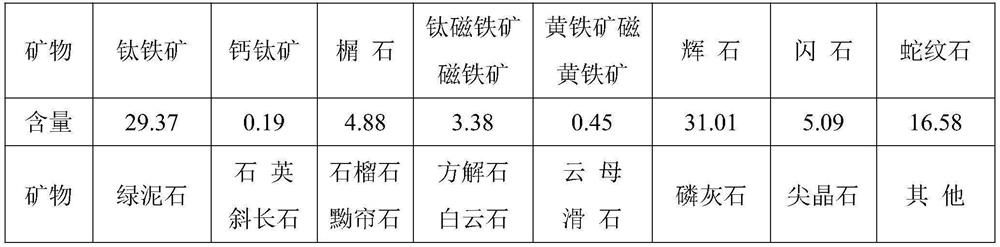

[0039](1) Add water to the ilmenite weak magnetic separation iron tailings to make the ore mass concentration 50%, and grind the ore until the grinding fineness is -75μm and the particle size content accounts for 85% of the grinding amount. Mineral products; the grinding products are subjected to weak magnetic separation, and then the obtained weak magnetic separation tailings are subjected to strong magnetic separation to obtain strong magnetic coarse concentrate; then water is added to the strong magnetic coarse concentrate to make the ore mass concentration 50 %, regrinding is carried out, and the strong magnetic coarse concentrate must be reground; the regrind strong magnetic coarse concentrate is transferred to the stirring tank, and water is added to adjust the slurry to make the ore mass concentration 35%, and then the concentration of the ore is 2.5m / s. S...

Embodiment 2

[0055] A low-grade refractory ilmenite dissolution pretreatment flotation method, comprising the following steps:

[0056] (1) Add water to the ilmenite weak magnetic separation iron tailings to make the ore mass concentration of 50%, and grind the ore until the grinding fineness is -30 μm and the particle size content accounts for 90% of the grinding amount, and the grinding is obtained. Mineral products; the grinding products are subjected to weak magnetic separation, and then the obtained weak magnetic separation tailings are subjected to strong magnetic separation to obtain strong magnetic coarse concentrate; then water is added to the strong magnetic coarse concentrate to make the ore mass concentration 50 %, regrinding is carried out, and the strong magnetic coarse concentrate must be reground; the regrind strong magnetic coarse concentrate is transferred to the stirring tank, and water is added to adjust the slurry to make the ore mass concentration 35%, and then the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com