Lubricating-free chain roller

A lubrication-free and chain-free technology, applied in the direction of transmission chains, etc., can solve the problems of difficult retention of lubricating oil and the decline of lubricating effect, and achieve the effect of long-lasting effect, reducing roller wear and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

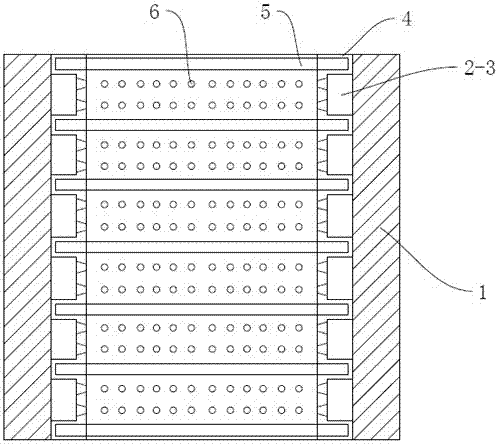

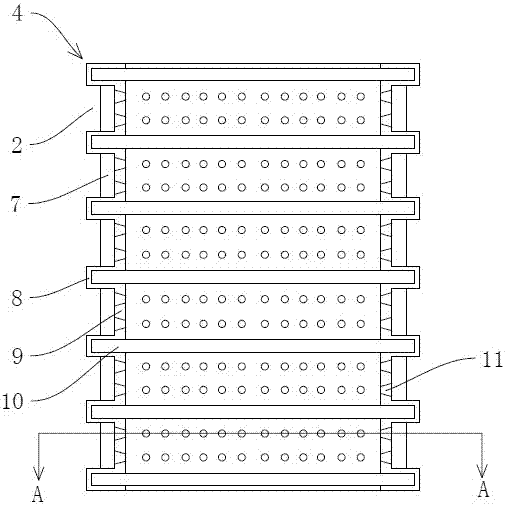

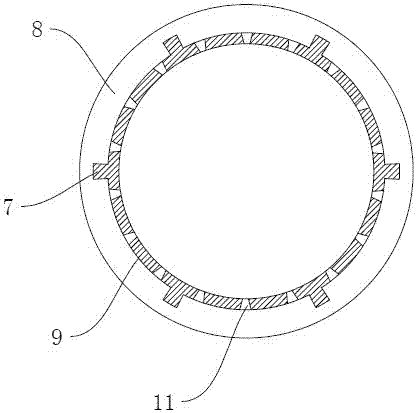

[0026] Embodiment 1: a kind of lubrication-free chain roller (see figure 1 figure 2 image 3 ), including a steel outer sleeve 1 and a copper inner sleeve 4 embedded in the inner wall of the outer sleeve, the copper inner sleeve and the steel outer sleeve are interference fit, the copper inner sleeve has an inner hole, and the inner hole matches the chain sleeve .

[0027] The copper inner sleeve includes a plurality of side-by-side rings 8 and copper walls 9 connecting adjacent rings. The inner walls of the copper walls are flush with the inner walls of the rings. In this embodiment, there are 7 rings, and the rings are Circular, the inside of the ring is provided with an open slot 10, the notch of the open slot faces the center of the ring, and a connecting arm 7 is connected between adjacent rings, the connecting arm is connected with the appearance of the copper wall, and the height of the connecting arm is It is smaller than the radial thickness of the rings, the conn...

Embodiment 2

[0031] Embodiment 2: A lubrication-free chain roller. The difference from Embodiment 1 is that the inner wall of the steel jacket is provided with a ring groove 12, and the position of the ring groove corresponds to the position of the copper wall, that is to say, it communicates with the ring cavity , oil-absorbing cotton 13 is embedded in the ring groove (see Figure 4 ), the ring groove is rectangular, and the thickness of the oil-absorbing cotton is smaller than the depth of the ring groove. Refer to Example 1 for all the other structures.

[0032] After the roller is immersed in food-grade oil under pressure, the oil-absorbing cotton will absorb the infiltrated food-grade oil for storage, and the oil-absorbing cotton is in contact with the graphite block in the ring cavity.

Embodiment 3

[0033] Example 3: A lubrication-free chain roller, the difference from Example 1 is that the copper inner sleeve is an assembled structure, the assembled position is at the copper wall, the ring is a complete structure, and the assembly adopts the male and female mating structure. see Figure 5 , the copper inner sleeve is divided into 5 intermediate assemblies 17 and 2 end assemblies 18, each intermediate assembly has a complete ring 8 and 1 / 2 high copper walls 9 on both sides of the ring, and the end assemblies It has a complete ring 8 and a 1 / 2 high copper wall 9 on one side of the ring, a male part 14 or a female part 15 is provided at the edge of the 1 / 2 copper wall, and each intermediate component and the end component There are male or female parts at intervals of 180°, and the adjacent two intermediate components are connected by the corresponding male and female parts, the edges of the copper walls are aligned, and the adjacent intermediate components respectively ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com