Shaft torsional vibration signal simulation test bench system and its application

A torsional vibration and experimental bench technology, applied in vibration testing, testing of machine/structural components, measuring devices, etc., can solve the problems of rotational speed fluctuation angle and angular acceleration characteristics without relatively accurate research results, complex structure of universal joints, Mixed problems, etc., to achieve the effect of solving the problem of torsional vibration parameter control accuracy, a reliable and effective test platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

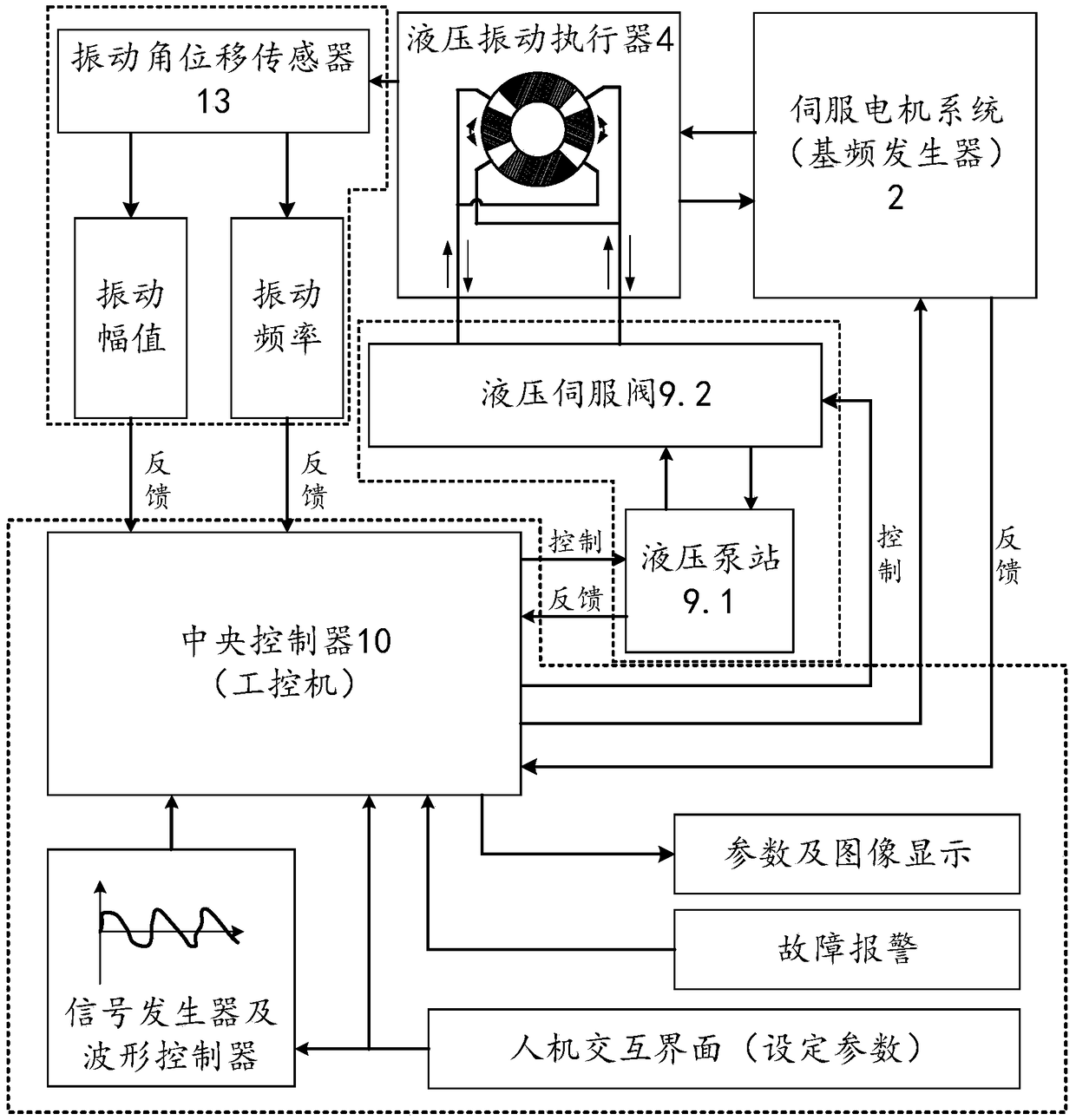

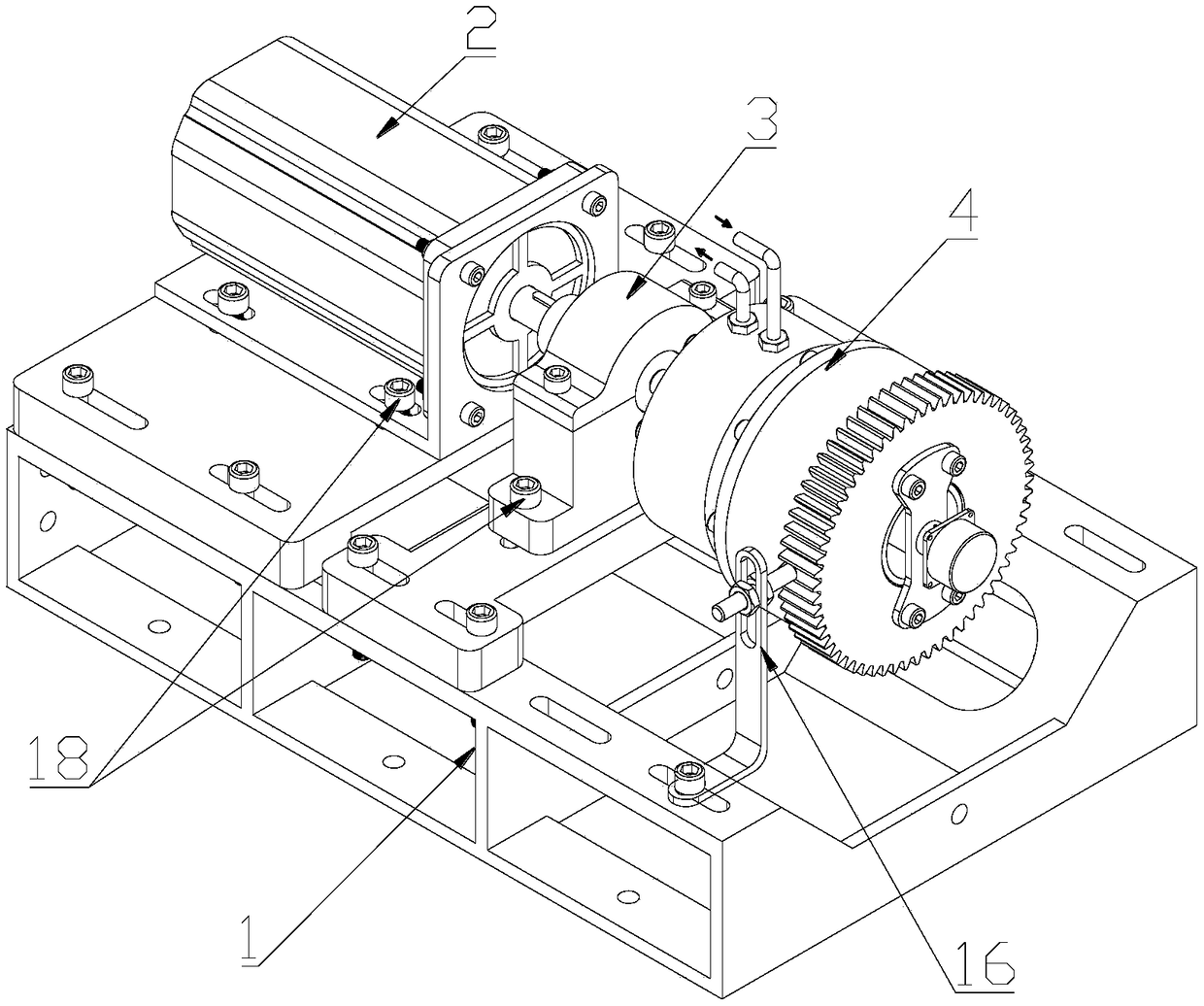

[0034] Such as Figure 1-9 As shown, the shafting torsional vibration signal simulation test bench system designed by the present invention includes a bench base 1, a servo motor 2, a bearing 3, a hydraulic vibration actuator 4, a hydraulic servo system, a central control system 10 and a vibration signal output device.

[0035] The servo motor 2 and the bearing 3 are fixedly installed on the stand base 1 through bolts 18 respectively.

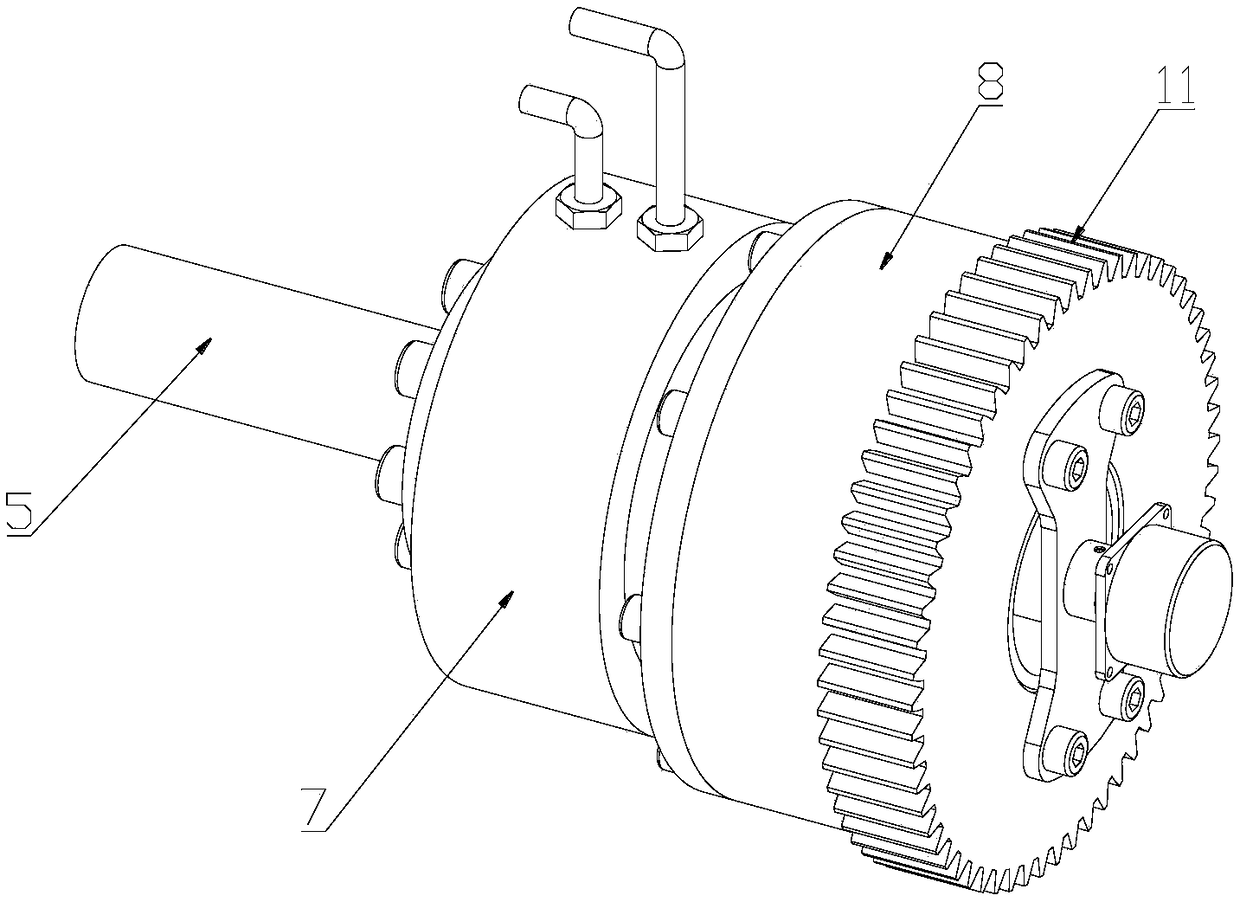

[0036]The hydraulic vibration actuator 4 includes a connecting shaft 5 , an oil distribution shaft 6 , an on-axis oil distributor 7 and a vibration housing 8 . The connecting shaft 5 is movably installed in the bearing 3, one end of which is connected with the output shaft of the servo motor 2, and the other end is fixedly connected with the oil distribution shaft 6.

[0037] The front section of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com