A Method of Obtaining Constant Elongation in Acceleration and Deceleration State

A technology of elongation, acceleration and deceleration, which is used in the production field of cold-rolled strip tempering machines, can solve the problems of unstable adhesion of the tempering liquid, excessive fluctuation of elongation, and the performance of the strip in the acceleration and deceleration flattening section does not meet the technological requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

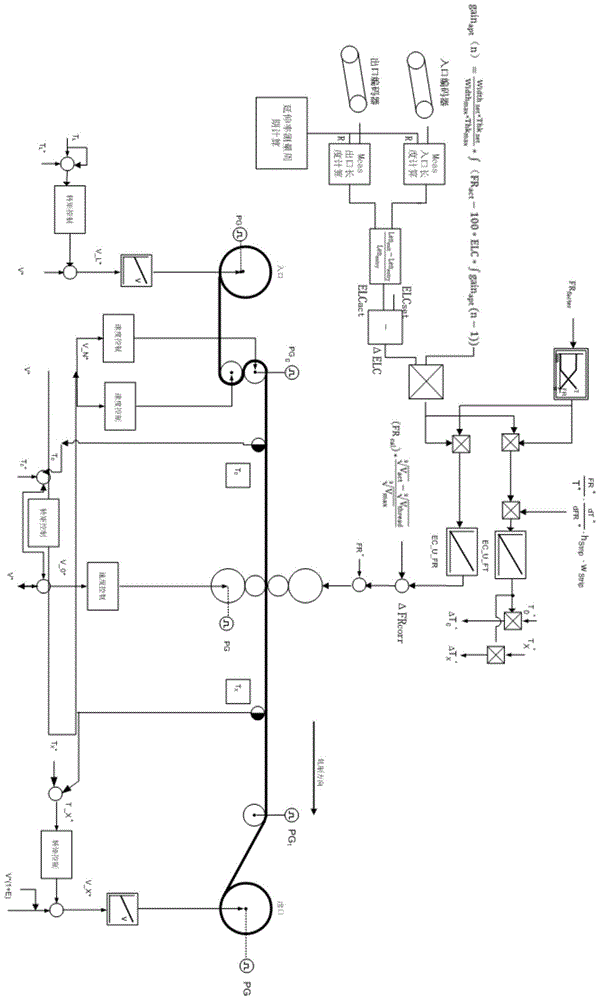

[0030] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

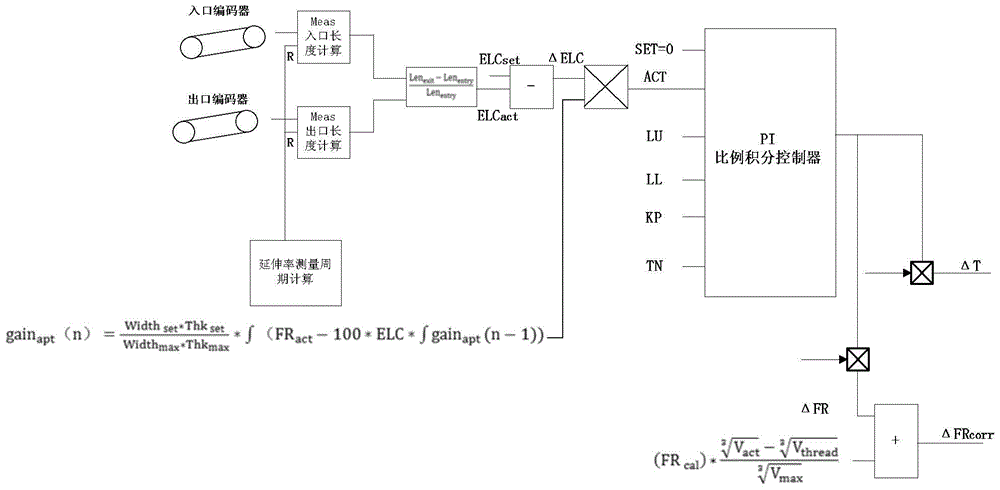

[0031] figure 1 It is a control principle diagram of an embodiment of the present invention. This embodiment provides a method for obtaining a constant elongation under acceleration and deceleration state, including the following steps:

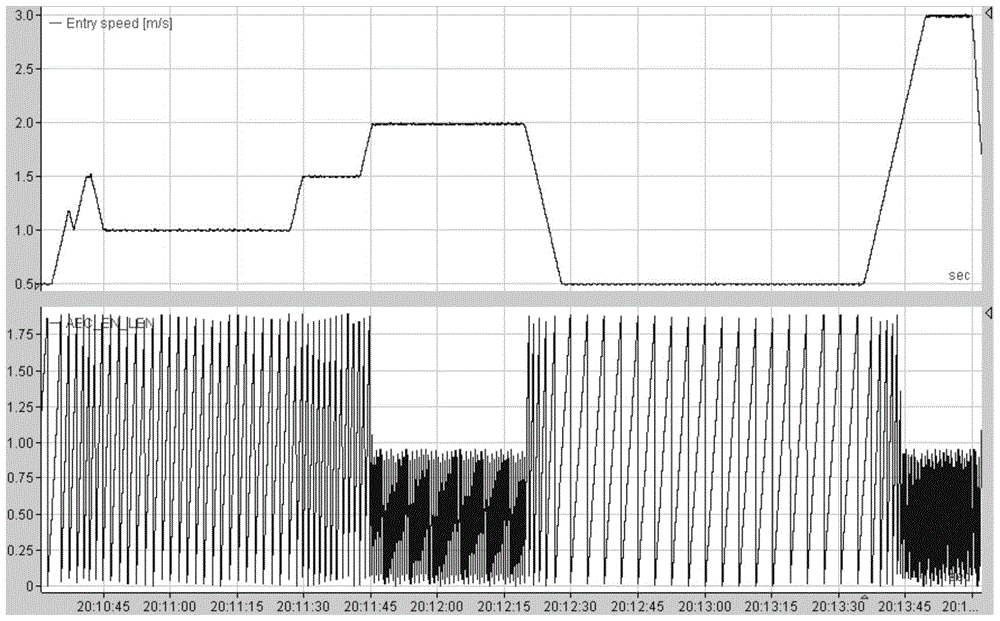

[0032] S1. Collect the entrance strip speed and exit strip speed respectively, set the variable length calculation period, and calculate the actual elongation value;

[0033] Based on the entrance strip speed or exit strip speed, the variable length calculation cycle is obtained according to its range, and the elongation is calculated; the rotation circumference of the measuring roller reaches the cycle value set at different speeds, and is used as the next elongation measurement Value starting point. That is, the actual value of the elongation is calculated every time the circumference of the measuring roller rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com