Combined slag removal system for grillage machine, and plate-mesh composite lateral-water-inflow grillage

A combination and grid machine technology, applied in the field of sewage pretreatment research, can solve problems such as easy clogging and difficult removal, and achieve the effects of simple operation, safe operation, and improved decontamination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

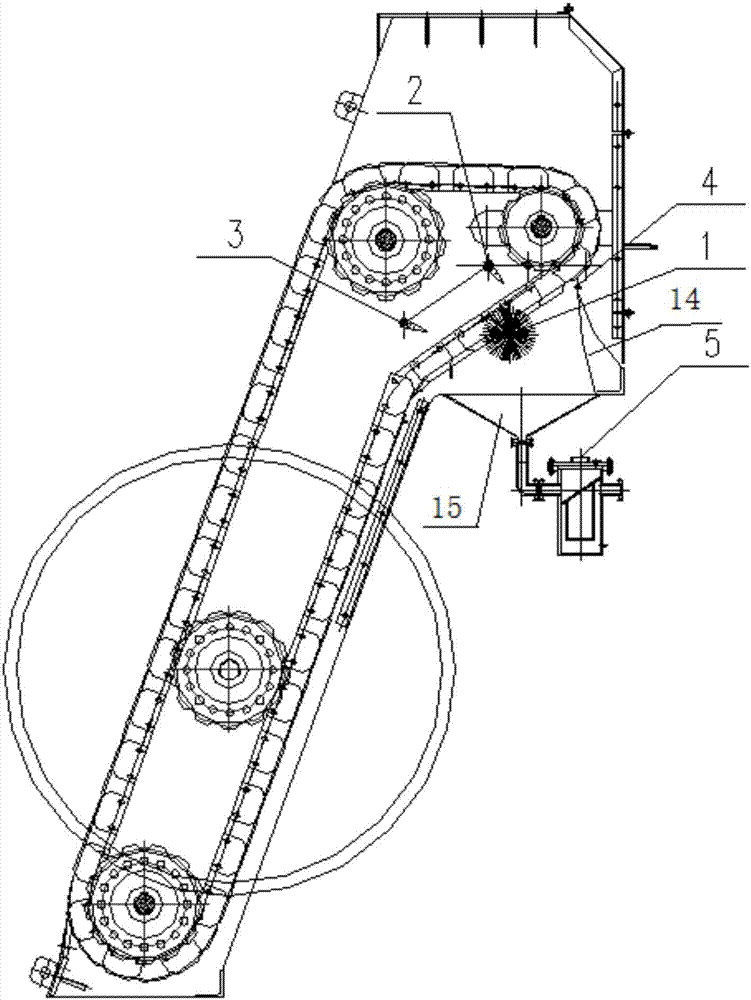

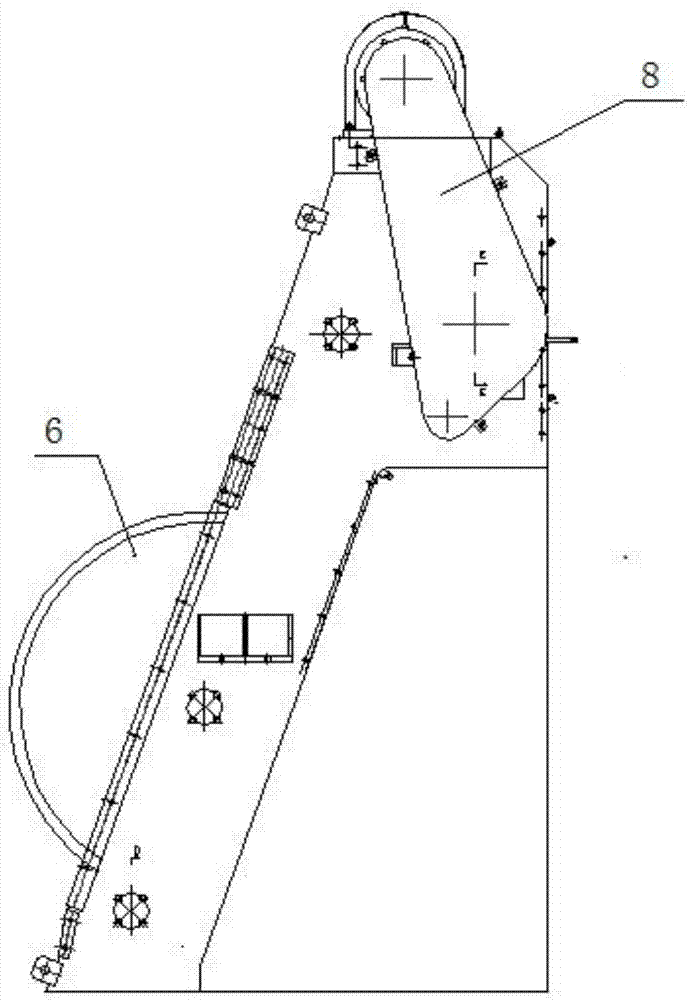

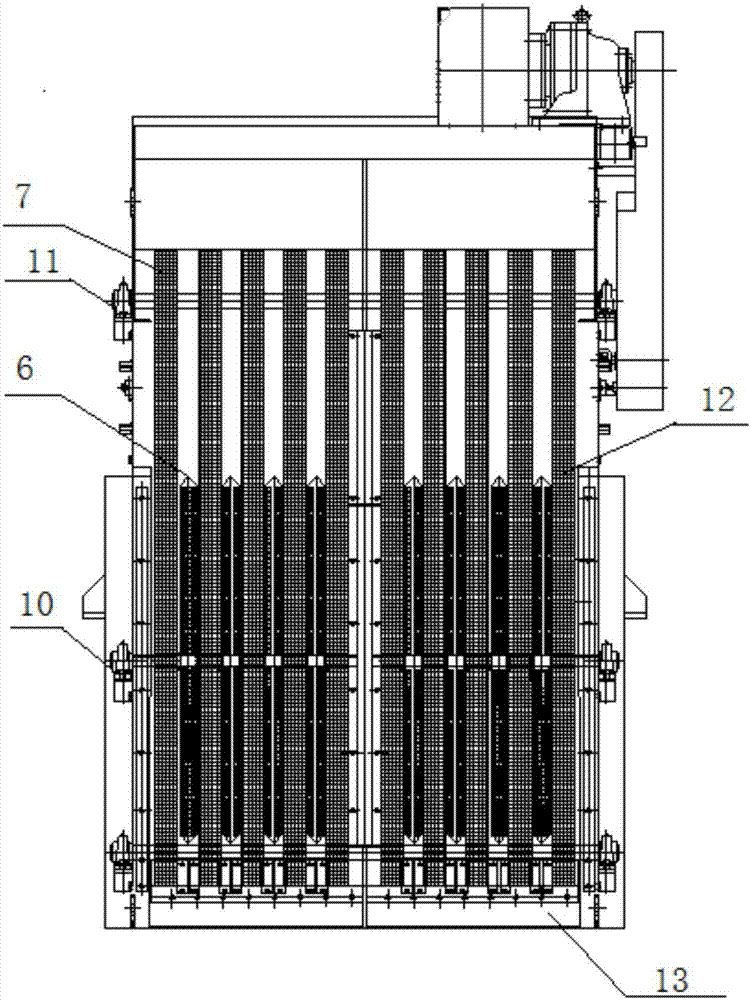

[0032] figure 1 Shown is an embodiment of a combined slag removal system for a grid machine according to the present invention. The combined slag removal system for a grid machine includes a rotating brush 1, a water flushing device 2, and an air flushing device 3. Rubber scraper 4 and hair collector 5.

[0033] The rotating brush 1 is located at the lower end outside the grid in the slag removal area, the rubber scraper 4 is located at the upper end outside the grid in the slag removal area; the water washing device 2 is located at the upper end inside the grid in the slag removal area, and the air washing device 3 is located at the inner lower end of the grid in the slag removal area; the rotating brush 1 is located at the grid in the slag removal area opposite between the water flushing device 2 and the air flushing device 3; the rubber scraper 4 is connected with an arc-shaped deflector 14, The arc-shaped deflector 14 leads to the bottom of the slag removal area; the hair...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com