Asphalt self-adhesive, and preparation method and use thereof

A self-adhesive and asphalt technology, which is applied in the direction of asphalt material adhesives, adhesives, adhesive types, etc., can solve problems such as non-compactness, easy contamination of cement slurry, lap joints, and artificial methods that cannot be peeled off, so as to increase composite strength. , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

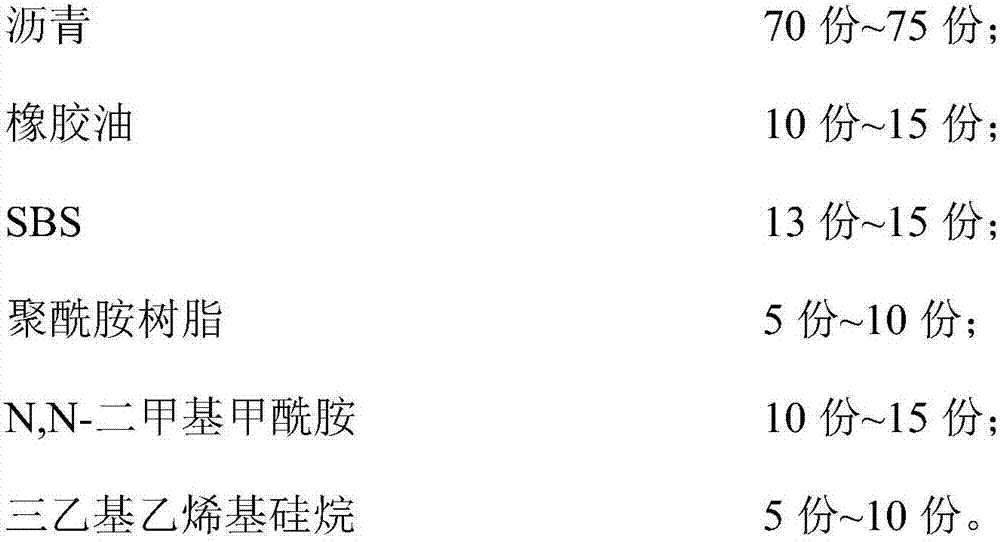

[0030] This embodiment provides an asphalt self-adhesive and a preparation method thereof, the asphalt self-adhesive comprises in parts by weight of each component:

[0031]

[0032] Wherein, the asphalt is PetroChina 90# asphalt, and the SBS is SBS791-H.

[0033] The preparation method is as follows: (1) Add the formulated amount of SBS to the formulated amount of asphalt, heat and disperse at 155°C for 4.5 hours, so that the SBS is uniformly dissolved in the asphalt, and obtain a rubber-modified asphalt system;

[0034] (2) Raise the temperature of the rubber-modified asphalt system obtained in step (1) to 190°C, and add a formula amount of rubber oil, polyamide resin, N,N-dimethylformamide and triethylvinylsilane to it, Stir to get asphalt self-adhesive.

[0035] The waterproof membrane was prepared by using the asphalt self-adhesive, and its properties are shown in Table 1.

Embodiment 2

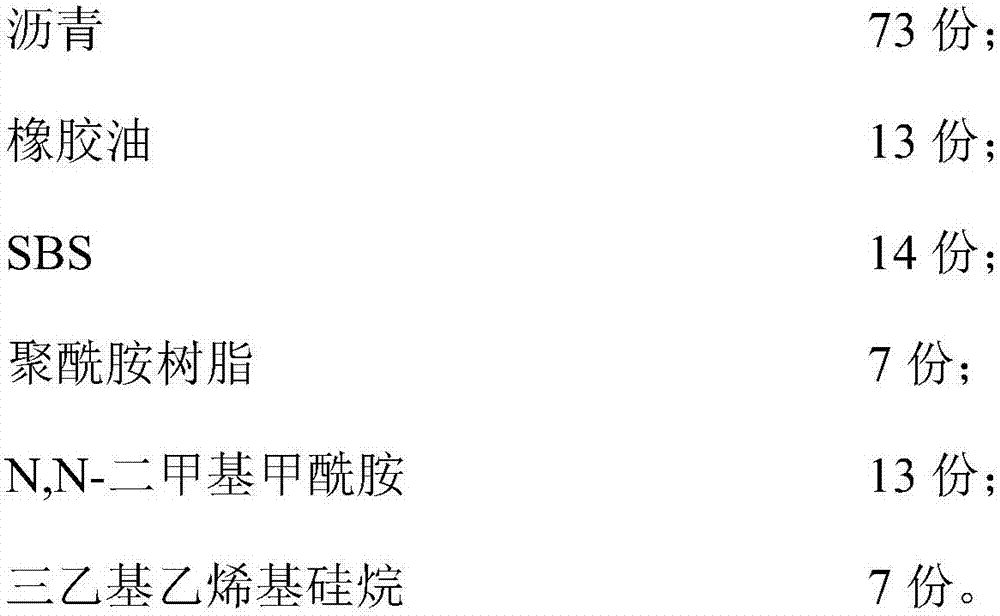

[0037] This embodiment provides an asphalt self-adhesive and a preparation method thereof, the asphalt self-adhesive comprises in parts by weight of each component:

[0038]

[0039]

[0040] Wherein, the asphalt is PetroChina 70# asphalt, and the SBS is SBS791-H.

[0041] Its preparation method is:

[0042] (1) Add the formulated amount of SBS to the formulated amount of asphalt, heat and disperse at 150°C for 5 hours, so that the SBS is uniformly dissolved in the asphalt, and obtain a rubber-modified asphalt system;

[0043](2) Raise the temperature of the rubber-modified asphalt system obtained in step (1) to 200°C, add the formulated amount of rubber oil, polyamide resin, N,N-dimethylformamide and triethylvinylsilane to it, and stir , to get asphalt self-adhesive.

[0044] The waterproof membrane was prepared by using the asphalt self-adhesive, and its properties are shown in Table 1.

Embodiment 3

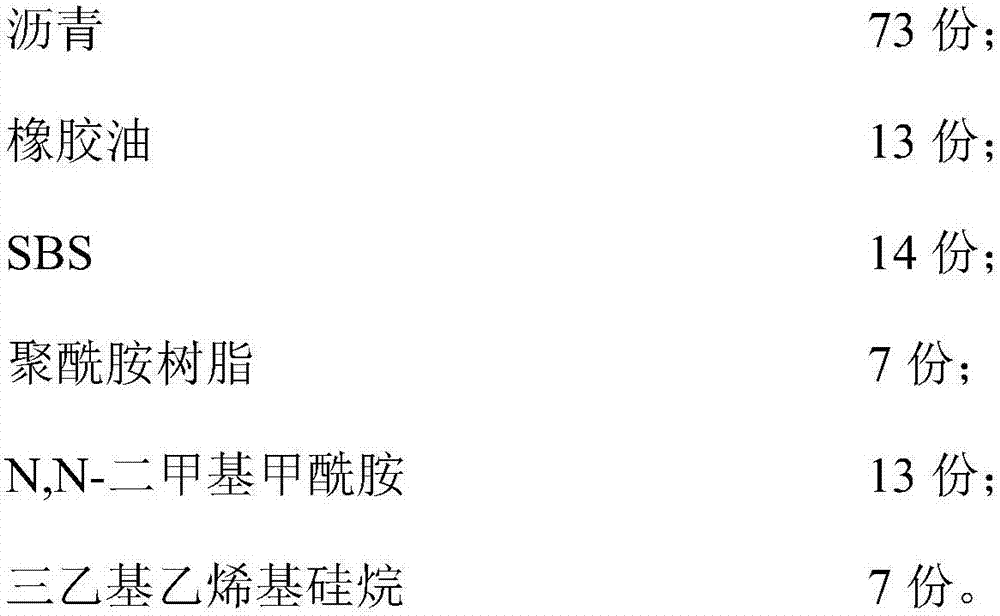

[0046] This embodiment provides an asphalt self-adhesive and a preparation method thereof, the asphalt self-adhesive comprises in parts by weight of each component:

[0047] Described asphalt self-adhesive glue it comprises by the weight part that each component accounts for:

[0048]

[0049] Wherein, the asphalt is PetroChina 70# asphalt, and the SBS is SBS791-H.

[0050] Its preparation method is:

[0051] Its preparation method is:

[0052] (1) Add the formulated amount of SBS to the formulated amount of asphalt, heat and disperse at 160°C for 4 hours, so that the SBS is uniformly dissolved in the asphalt, and obtain a rubber-modified asphalt system;

[0053] (2) Raise the temperature of the rubber-modified asphalt system obtained in step (1) to 180°C, add the formulated amount of rubber oil, polyamide resin, N,N-dimethylformamide and triethylvinylsilane to it, and stir , to get asphalt self-adhesive.

[0054] The waterproof membrane was prepared by using the asphal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com