Assembled sandwich heat preservation concrete shear wall structure non-dismantling formwork system

A technology of thermal insulation concrete and free formwork, which is applied in the field of building wall components, can solve the problems of slow building construction speed, long construction period, and large amount of on-site construction, so as to shorten the construction period, speed up the construction progress, and improve the quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

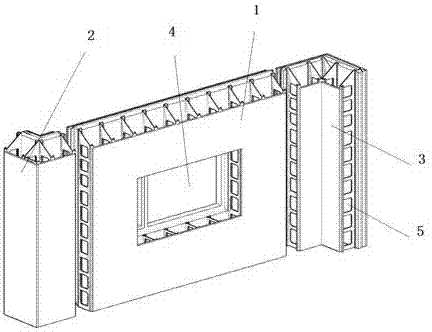

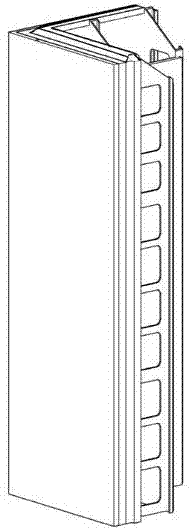

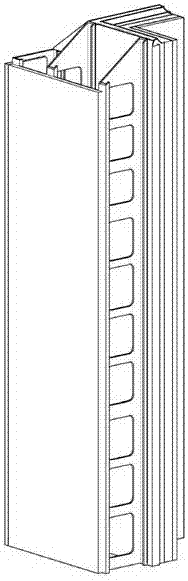

[0027] The first embodiment of the demolition-free formwork system of the prefabricated sandwich thermal insulation concrete shear wall structure of the present invention includes a wall panel 1 and also includes corners, and the corners include male corners 3 and female corners 2 . The composition of the wallboard and the corner all includes a steel warehouse 14, an outer wallboard, an inner protective board 15 and a bolt 6. The steel silos, outer wall panels and inner protective panels of the wall panels are in the shape of flat plates; the corner steel silos, outer wall panels and inner protective panels are in the shape of knuckles. The steel silo is a hollow steel silo formed by welding several cold-formed C-shaped steels. The outer wall panel is composed of a rigid non-combustible material facing layer 11, a protective layer 12 and an insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com