Mutual-lock hammer valve mechanism for improving working performance of hydraulic impactor

A technology of hydraulic impactor and working performance, which is applied to the driving device for drilling in the wellbore, drilling equipment, earthwork drilling and production, etc. It can solve the problems of the hammer valve being separated from closing and not being tight, so as to ensure the reliability and sealing , Improve working performance, improve the effect of closing and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

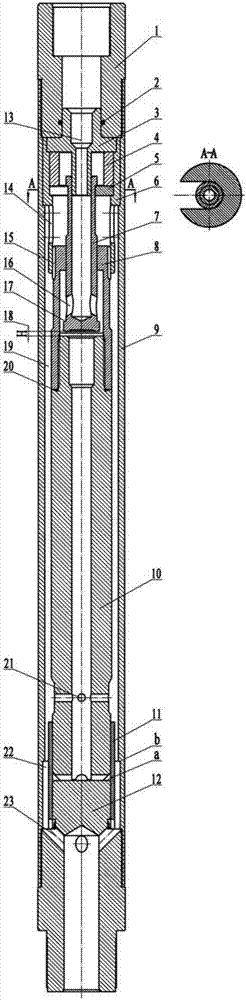

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0009] As shown in Figure 1, the interlocking hammer valve mechanism provided by the present invention can improve the working performance of the hydraulic impactor. The interlocking hammer valve mechanism includes an upper joint 1, a sealing ring 2, a drainage tube 3, and a positioning sleeve 4 , limit pad 5, upper guide sleeve 6, live valve 7, upper joint 8 of the hammer rod, outer pipe 9, hammer rod 10, lower cylinder liner 11, impact anvil 12. The upper joint 1 and the outer pipe 9 are rigidly connected by thread, and the lower part of the connecting thread of the outer pipe 9 is processed with an inner hole concentric with the diameter of the thread and a limit step. The upper guide sleeve 6 is put into the inner hole from the upper opening of the outer pipe 9 Inside, the outer diameter of the upper guide sleeve 6 is sliding and sealed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com