Thermoelectric decoupling and peak shaving system

A heating system and peak shaving technology, applied in heating systems, heat recovery systems, household heating, etc., can solve problems such as the limitation of user groups that cannot meet large-area heating, heat storage, cooling, and heating, etc. Achieve the effect of alleviating the dilemma of consumption, reducing the amount of on-grid electricity, and developing a broad market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

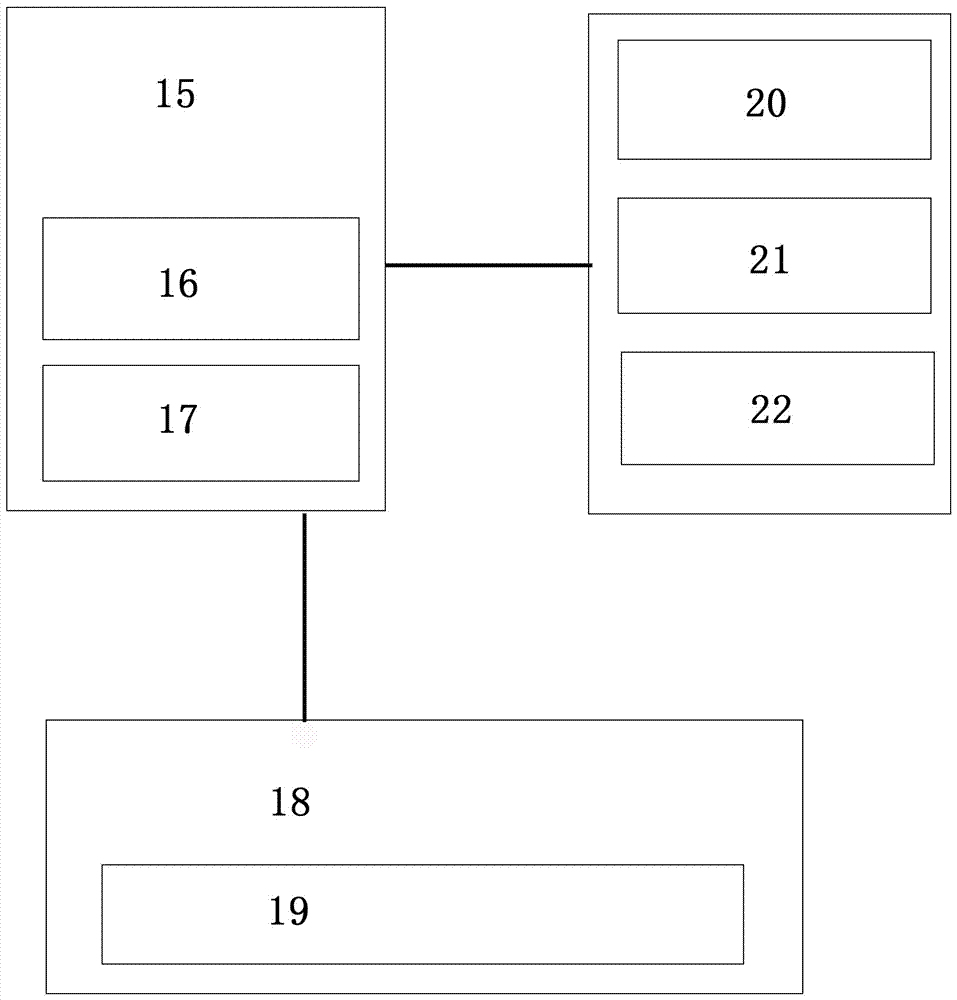

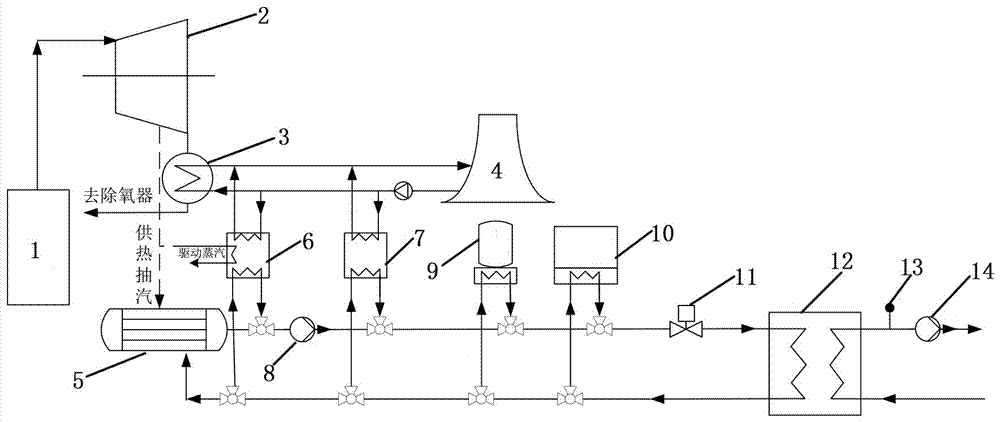

[0036] Such as figure 1 and figure 2 As shown, a thermoelectric decoupling peak shaving system includes a thermal power plant heating system 20 for heat supply and extraction, a heating network system, a heating network system, a power grid and a power plant peak shaving control platform 15, and a heat storage and discharge operation management platform 18 for the heat network. , Circulating water waste heat heat pump recovery system 21 and electric boiler heating system 22 .

[0037] In this embodiment, the heat supply pipe network system includes a primary heat supply pipe network, a secondary heat supply pipe network, and a thermal station 12 located at the junction of the primary heat supply pipe network and the secondary heat supply pipe network.

[0038] In this embodiment, the primary heat supply pipe network is connected to the heating system of the heat supply and extraction steam heating network, the circulating water waste heat heat pump recovery system 21, and th...

Embodiment 2

[0057] Embodiment 2 is similar to Embodiment 1, the difference is that a thermoelectric decoupling peak regulation system in Embodiment 2 includes a thermal power plant heating system 20 for heating and extracting steam heating network, a heating pipe network system, a power grid and a power plant regulation system. Peak control platform 15, heat network heat storage and discharge operation management platform 18, circulating water waste heat heat pump recovery system 21.

[0058] In this embodiment, the heat supply pipe network system includes a primary heat supply pipe network, a secondary heat supply pipe network, and a thermal station 12 located at the junction of the primary heat supply pipe network and the secondary heat supply pipe network.

[0059] In this embodiment, the primary heat supply pipe network is connected to the heating system of the heat supply and extraction steam heating network, and the circulating water waste heat heat pump recovery system 21 through wa...

Embodiment 3

[0073] A thermoelectric decoupling peak shaving system, including a thermal power plant heat supply extraction steam heating network heating system 20, a heating pipe network system, a power grid and a power plant peak shaving control platform 15, a heat storage and discharge operation management platform 18 of a heat network, and an electric boiler heating system twenty two.

[0074] In this embodiment, the heat supply pipe network system includes a primary heat supply pipe network, a secondary heat supply pipe network, and a thermal station 12 located at the junction of the primary heat supply pipe network and the secondary heat supply pipe network.

[0075] In this embodiment, the primary heating pipe network is connected to the electric boiler heating system 22 through a water delivery pipe; the primary heating pipe network is provided with a secondary circulation pump 8 .

[0076] In this embodiment, the secondary heating pipe network is connected to the user end, and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com