In-situ biaxial crack growth route auto-tracing measurement system and measurement method

A crack propagation and automatic tracking technology, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve the problem that it is difficult to judge which direction the crack tip is facing beyond the field of view, and cannot accurately draw the expansion path. , the crack tip exceeds the field of view, etc., to solve the contradiction between the field of view and measurement accuracy, solve the contradiction between the imaging accuracy and the field of view, and improve the resolution of the camera.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

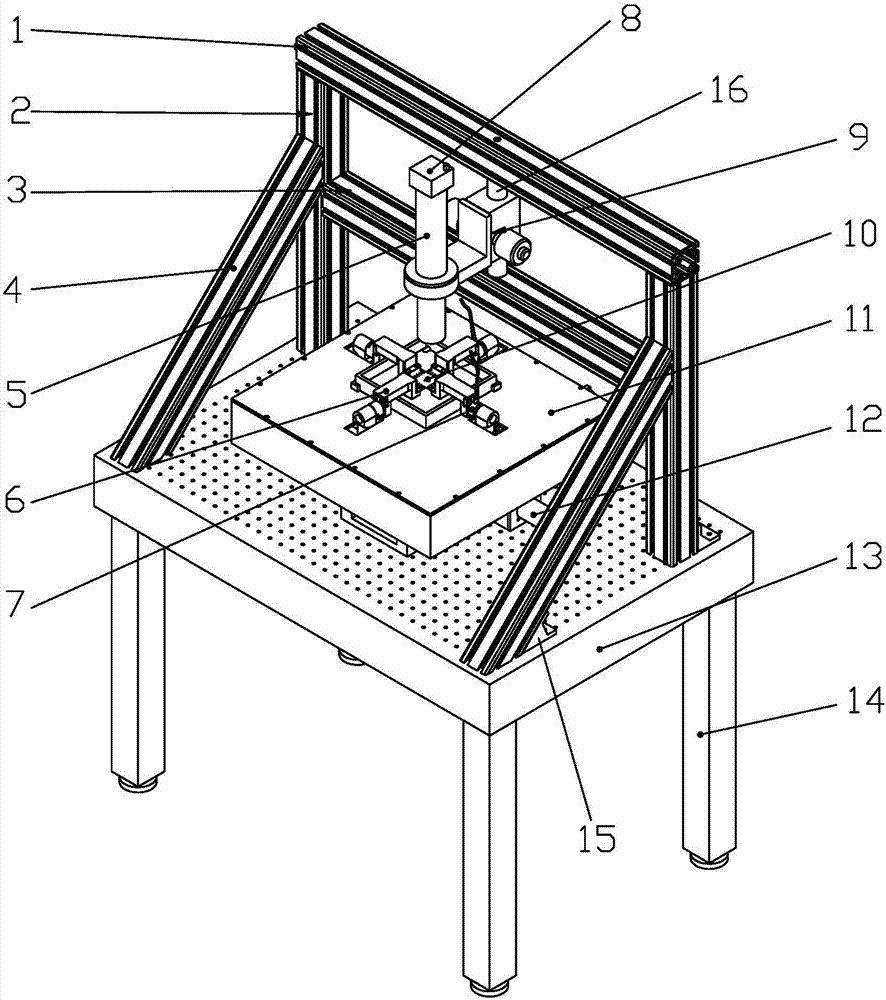

[0054] An in-situ biaxial crack propagation path automatic tracking measurement system and measurement method of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0055] An in-situ biaxial crack propagation path automatic tracking measurement system of the present invention is to carry out in-plane bidirectional loading on material samples or components such as metals, polymer materials, and composite materials, and simultaneously use a microscope and X, Y bidirectional mobile platforms to observe A test device that can change the shape of the crack on the surface of the sample, automatically track the tip of the crack, and monitor the growth status of the crack.

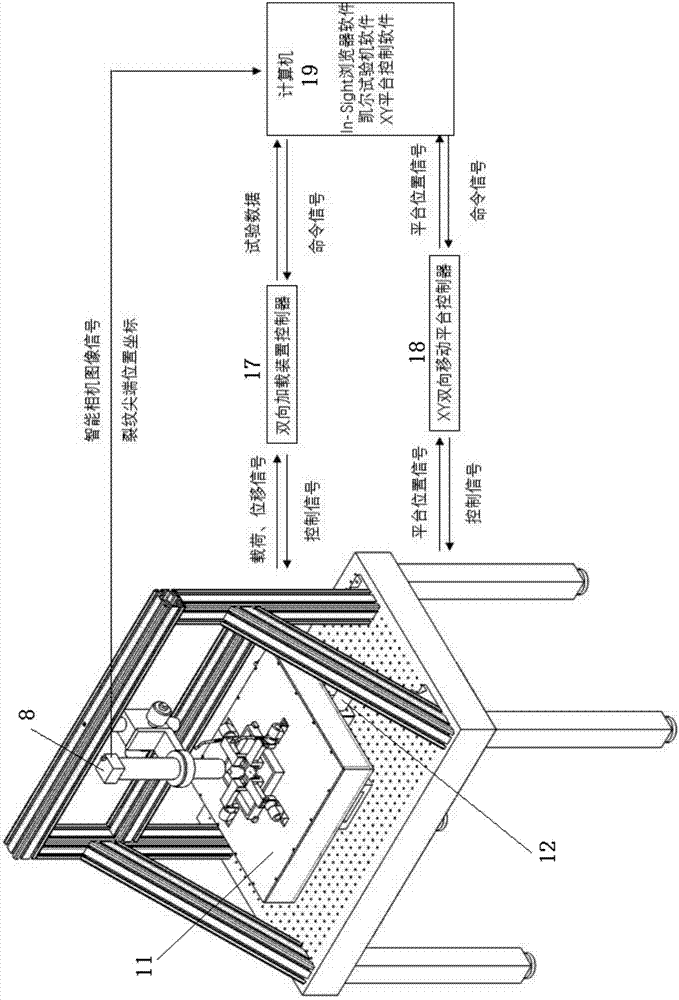

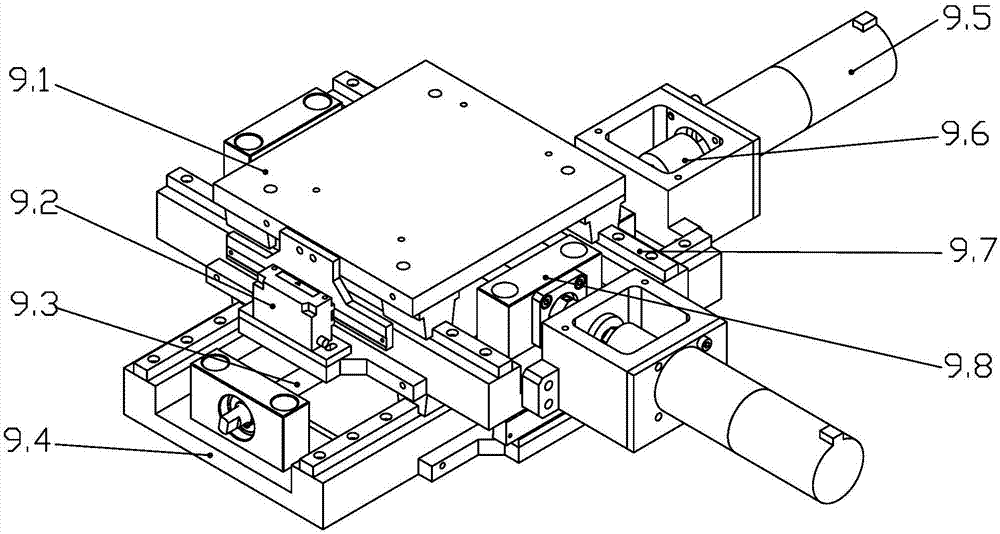

[0056] Such as figure 1 , figure 2 As shown, an in-situ biaxial crack propagation path automatic tracking measurement system of the present invention includes a computer 19, and an optical table composed of an optical table top 13 and an opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com