Dental implant maxillary sinus lift reamer

A technology for dental implants and reaming drills, which is used in dental implants, dentistry, dental prosthetics, etc., can solve the problem that the drill bit cannot achieve local reaming at the end, and achieves the effect of high implant success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

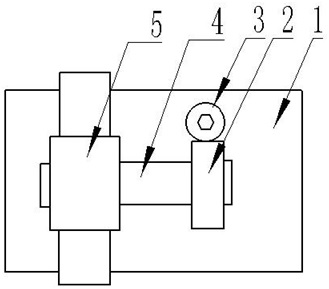

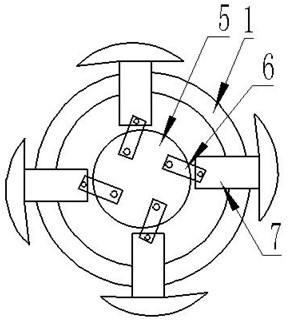

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments: Among the figures: 1 drill rod, 2 worm gears, 3 worm screws, 4 rotating shafts, 5 rotating disks, 6 connecting rods, and 7 telescopic rods.

[0010] As shown in the figure, the lifting and reaming drill in the maxillary sinus of the implant has a power connection joint at the end of the drill rod 1, and four holes are evenly arranged on the side of the front end of the drill rod in the circumferential direction, and there are telescopic rods 7 in the holes.

[0011] The outer end of the telescopic rod 7 passes through the side of the drill pipe 1, and is provided with an arc-shaped surface. The surface of the arc-shaped surface has grinding lines. The axis is parallel to the axis of the drill pipe 1. When the turntable 5 rotates, it drives the connecting rod 6, and the connecting rod 6 drives the telescopic rod 7 to realize the translati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com