Alfalfa planting method adopting full-biodegradable mulching film mulching

A technology for degrading mulch and planting methods, applied in botany equipment and methods, plant protection, plant cultivation, etc., can solve the problem that biodegradable mulch cannot take into account both degradation rate and mechanical strength, mulch fragments are mixed into alfalfa, and alfalfa is successfully planted It can improve the success rate of planting, strengthen the effect of suppressing weeds, and enhance competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In the alfalfa planting method covered with fully biodegradable plastic film according to the present invention, the preparation method of the modified calcium carbonate comprises the following steps: (1) by mass parts, weigh 100 parts of nanometer calcium carbonate powder, add 10 parts The dehydrated ethanol solution of the composite coupling agent with a concentration of 20wt% is continuously stirred and heated in a high-speed mixer for 1-2 hours, the speed is 1000-2000 rpm, and the temperature is 70-80 ° C. After filtering, it is dried at 100-120 ° C to obtain primary carbonic acid Calcium powder; wherein the components of the composite coupling agent are aluminum zirconate coupling agent, γ-methacryloxypropyltrimethoxysilane and titanate coupling agent, and the weight ratio is 1:1:1 (2) Add 100 parts of primary treatment calcium carbonate powder, 5-10 parts of sodium silicate and 50-100 parts of deionized water in the reaction flask, then slowly add 2.5wt% hydrochlor...

Embodiment 1

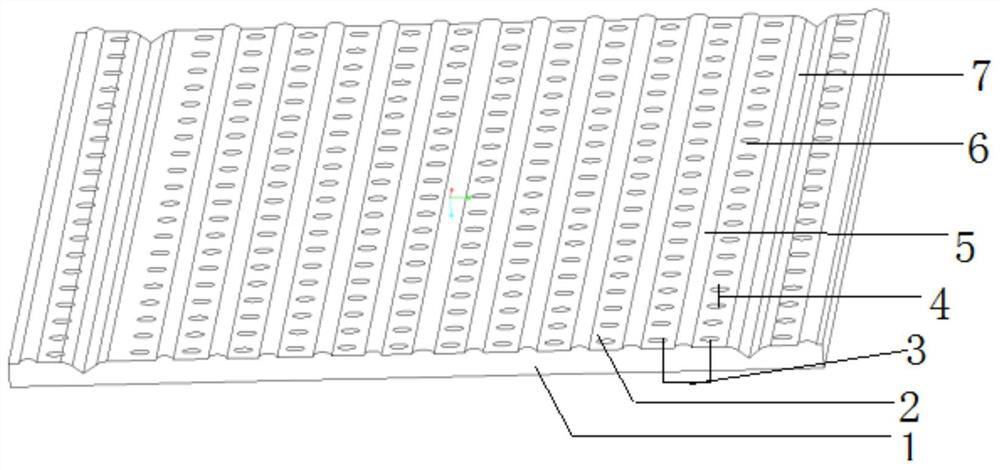

[0054] Such as figure 1 According to the specifications shown, the experiment of planting alfalfa with fully biodegradable plastic film was carried out in Zhangye City, Gansu Province on March 27.

[0055] (1) Preparation of fully biodegradable mulch film: (1) by weight, 20 parts of modified starch and 30 parts of modified calcium carbonate are mixed in a ball mill in proportion, add 8 parts of absolute ethanol and 0.6 part of citric acid, at temperature Grind at 100° C. for 1-2 hours, and dry to obtain a starch / calcium carbonate composite filler; (2) by weight, will contain the starch / calcium carbonate composite filler, 100 parts of full biodegradable resin (polylactic acid (PLA) The mass ratio of poly(adipic acid / butylene terephthalate (PBAT) is 0.1:1), 30 parts of additives and 1 part of carbon black and other raw materials are weighed according to the set ratio and added to the mixing hopper for stirring After uniformity, it enters the single-screw extruder with exhaust f...

Embodiment 2

[0061] Such as figure 1 According to the specifications shown, the experiment of planting alfalfa with fully biodegradable plastic film was carried out in Tongliao City, Inner Mongolia Autonomous Region on August 22.

[0062] (1) Preparation of fully biodegradable mulch film: (1) by weight, 40 parts of modified starch and 50 parts of modified calcium carbonate are mixed in a ball mill in proportion, and 8 parts of absolute ethanol and 0.6 part of citric acid are added. Grind at 80° C. for 1 hour, and obtain starch / calcium carbonate composite filler after drying; Butylene dicarboxylate (PBAT), polybutylene succinate-butylene adipate (PBSA) and polymethylethylene carbonate (PPC), mass ratio 1:0.1:0.1) and 10 The raw materials of additives are weighed according to the set ratio and added to the mixing hopper to stir evenly, and then enter the single-screw extruder with exhaust function for blow molding; (3) The blow-molded film After entering the traction station, after trimmin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com