Rinsing circulating system for press-formed television back plates

A technology of stamping forming and circulation system, applied in the field of cleaning, can solve the problems of wasting water resources, low cleaning efficiency, etc., and achieve the effect of full recycling, saving, simple structure, and realizing recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

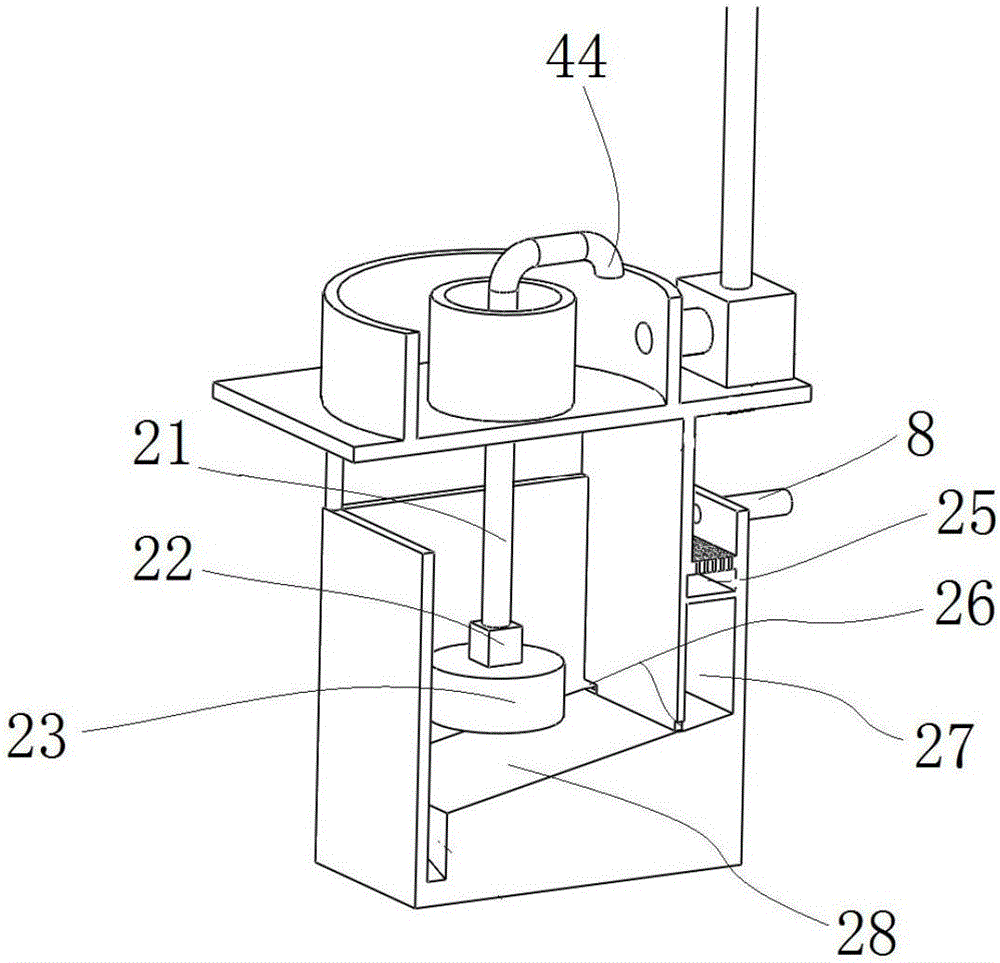

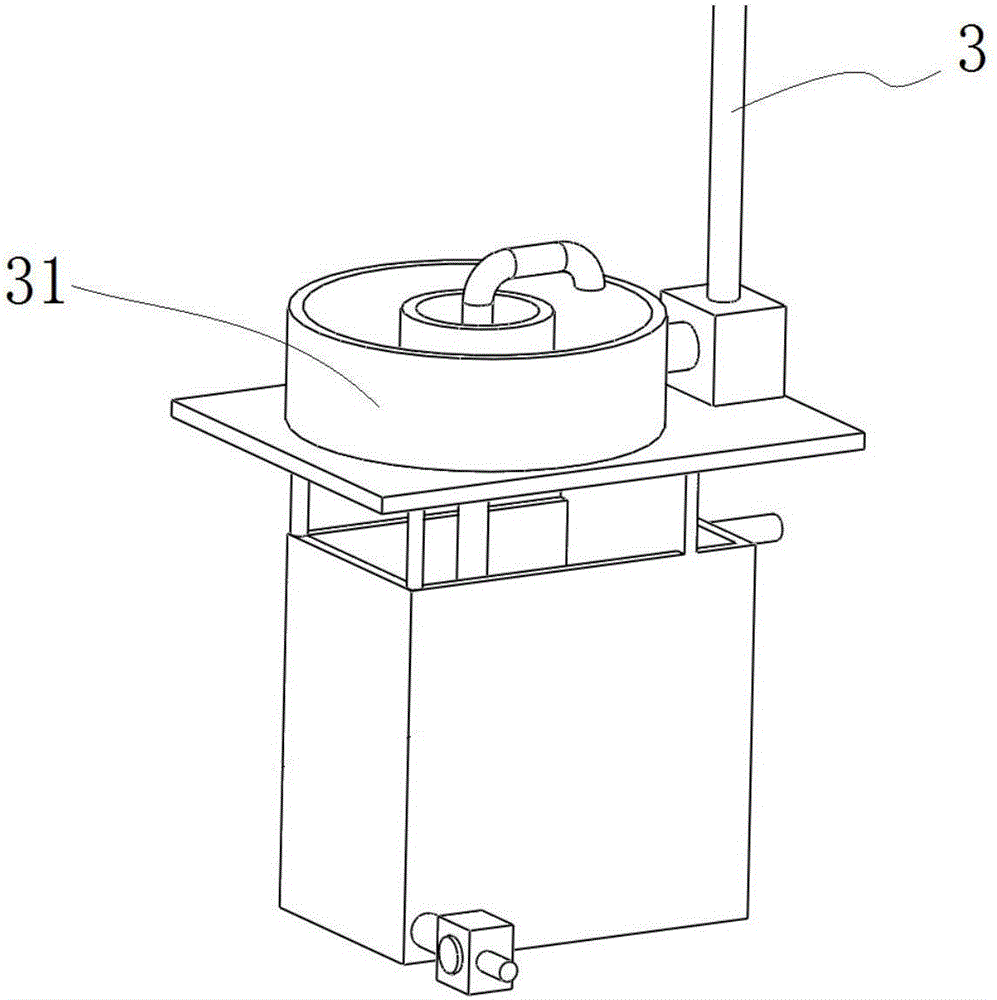

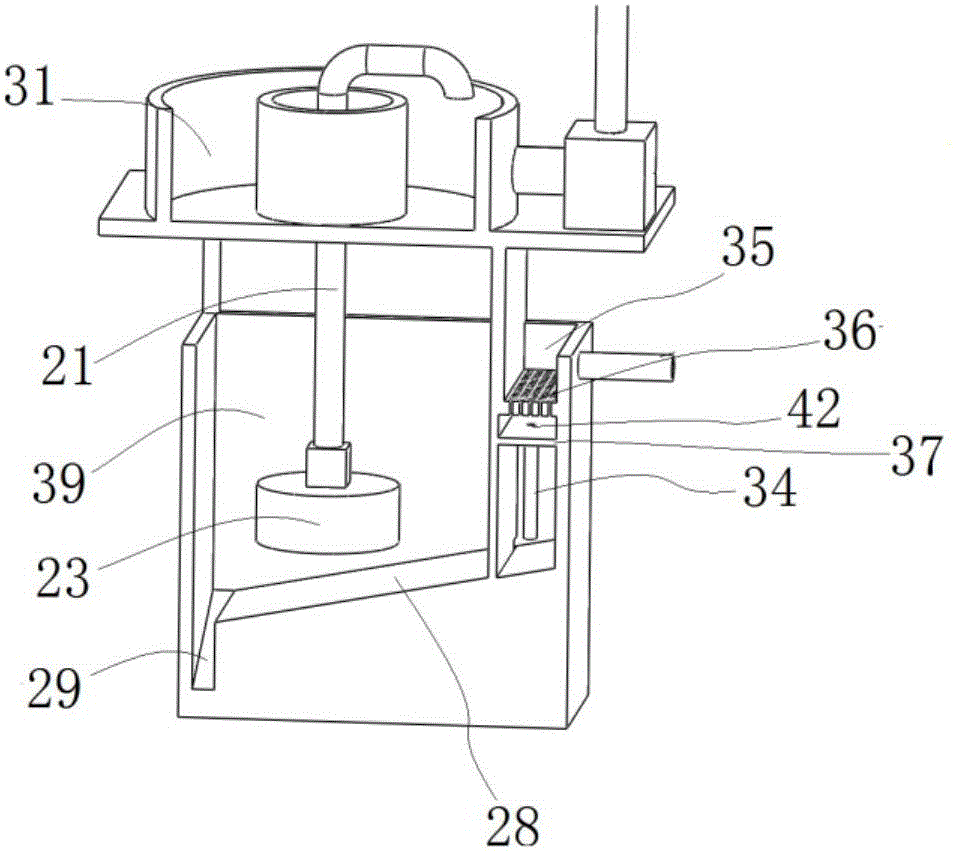

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] as attached figure 1 As shown, the press-formed television backboard flushing circulation system includes a water storage tank 2, a diversion water tank 7, a filter water tank 11, a shower 6, a TV backplane conveyor belt 9 and a recovery water tank 10; several of the showers 6 is arranged on the top of the TV backboard conveyor belt 9, and several sprinklers 6 are evenly distributed in an array along the length direction of the TV backplane conveyor belt 9, and the water nozzles of the showers 6 are opposite to the transmission surface of the TV backplane conveyor belt 9. It should be set; the diversion water tank 7 is arranged above several showers 6, and several water outlets of the diversion water tank 7 are respectively connected to the water inlets of several showers 6; the recovery water tank 10 is arranged below the conveyor belt 9 of the TV backplane Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com