A Grouting Reinforcement Structure and Design Method for the Overlying Soil Layer of Karst Cave in Karst Area

A technology for grouting reinforcement and covering soil layer, which is used in infrastructure engineering, soil protection, construction, etc., and can solve problems such as difficulty in dealing with deep buried karst caves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

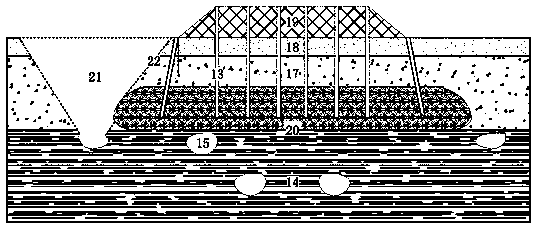

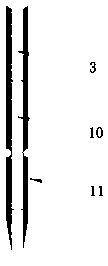

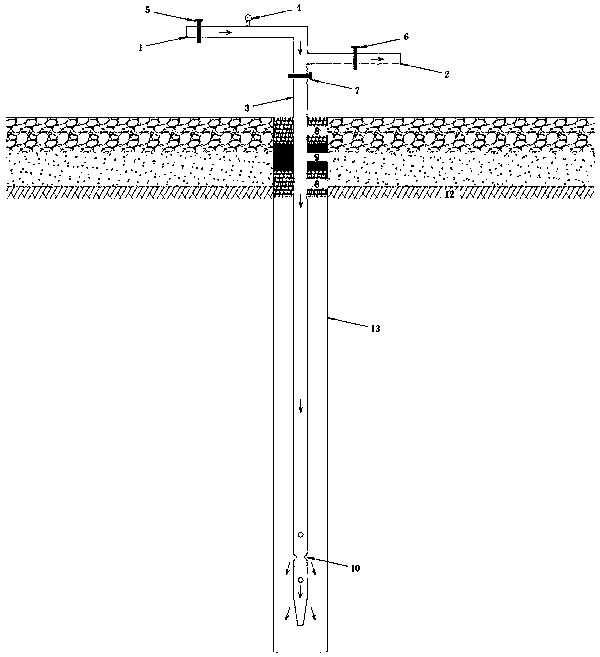

[0035] Such as figure 1 As shown, a grouting reinforcement structure for the overlying soil layer of a karst cave in a karst area, which includes limestone 14, karst cave 15, consolidated grouting layer 16, breccia 17, silty clay 18 and roadbed filling 19 from bottom to top . The consolidated grouting layer 16 needs to use grouting equipment, which is formed by grouting and consolidating from the borehole 13 into the breccia 17, and the thickness is generally 5-8m.

[0036] The actual distribution length of the consolidated grouting layer 16 and the karst cave 15 is consistent, and the width is calculated according to the width of the bottom of the subgrade, and the width d of the impact of the collapse is added. The depth of the borehole 13 is 2m above the earth-rock interface 20, and is divided into two types: vertical hole and inclined hole. The influence width d, the grouting diffusion width w, etc. are calculated.

[0037] A method for designing a grouting reinforced s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com