Active underground instrument heat management system and method

A thermal management system and active technology, applied in the operation mode of machines, lighting and heating equipment, machines using electric/magnetic effects, etc., can solve problems such as difficulty in purchasing, export control, and high price, and achieve cost reduction , save space, reduce the effect of contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention is proposed on the premise of solving a feasible processing technology. The present invention will be further described in detail below in conjunction with specific drawings.

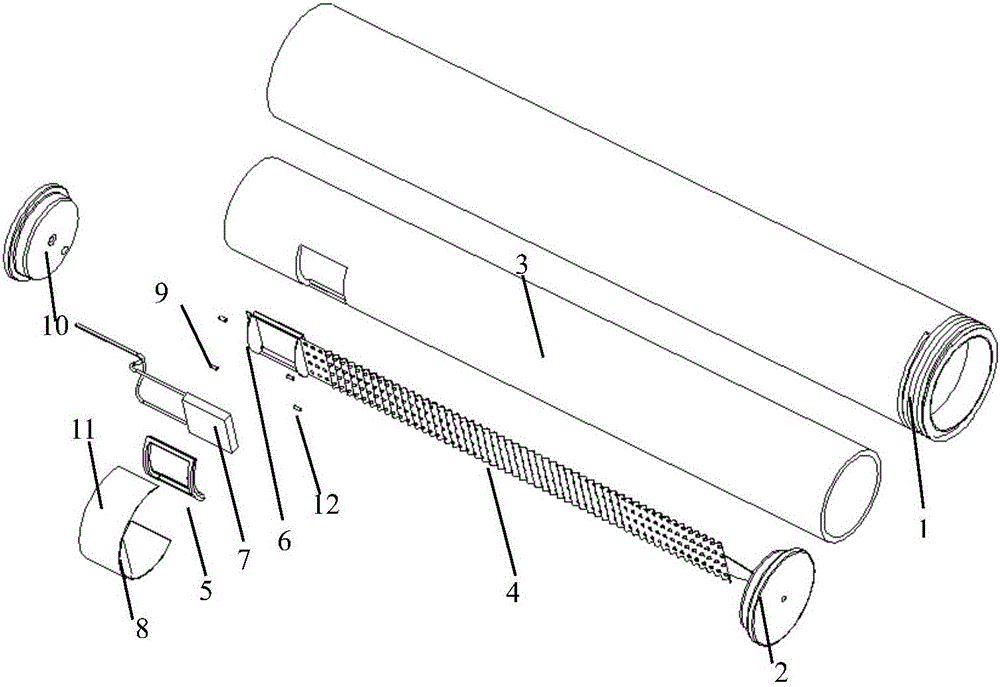

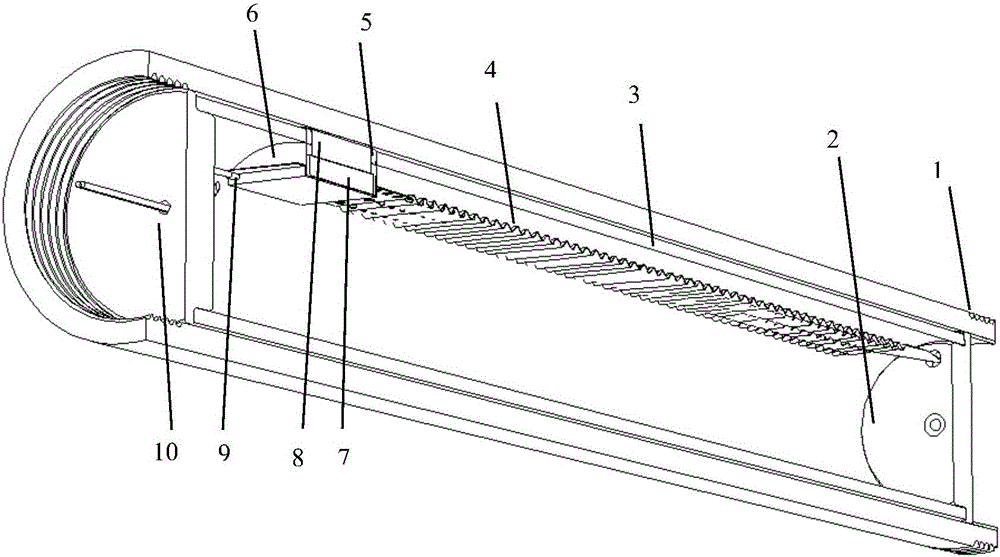

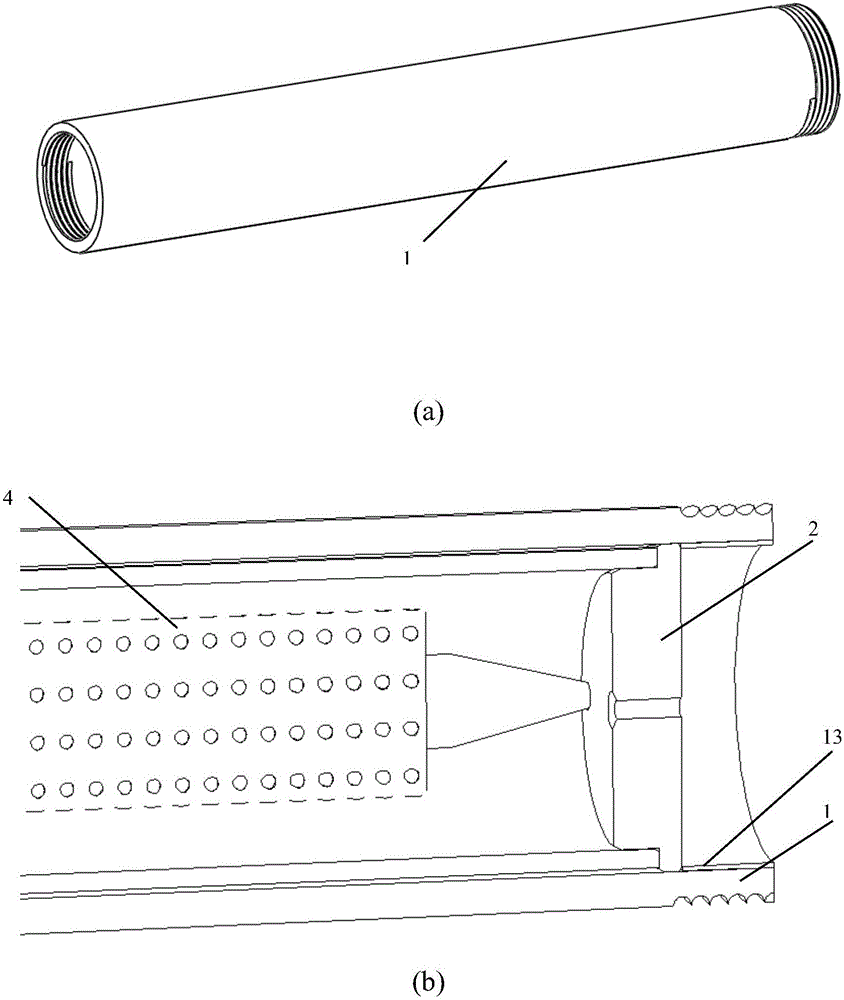

[0051] Reference figure 1 As shown, an active downhole instrument thermal management system of the present invention includes a pressure-bearing cavity 1, a sealed bottom cover 2, a heat preservation cavity 3, a corrugated porous fin 4, a fan-shaped sealing frame 5, a chip box 6, and a semiconductor cooling chip 7. Sector-shaped thermally conductive copper block 8, wire barrel 9, sealing top cover 10, semi-circular arc copper tile 11 and fixing bolt 12.

[0052] Reference Figure 1 to Figure 5 As shown, there is a fan-shaped notch 16 near the top of the heat-preserving cavity 3. The copper fan-shaped chip box 6 has the characteristics of small head and small end. The chip box 6 can be placed in the fan-shaped notch of the heat-preserving cavity 3 without slipping off; the chip b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com