Novel gas tank aeroelastic model system

An aeroelasticity, gas tank technology, applied in aerodynamic tests, measuring devices, instruments, etc., can solve the problems of difficulty in ensuring the correctness of the test, inability to accurately simulate the actual state of the piston and the cabinet, and achieve the effect of accurate test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

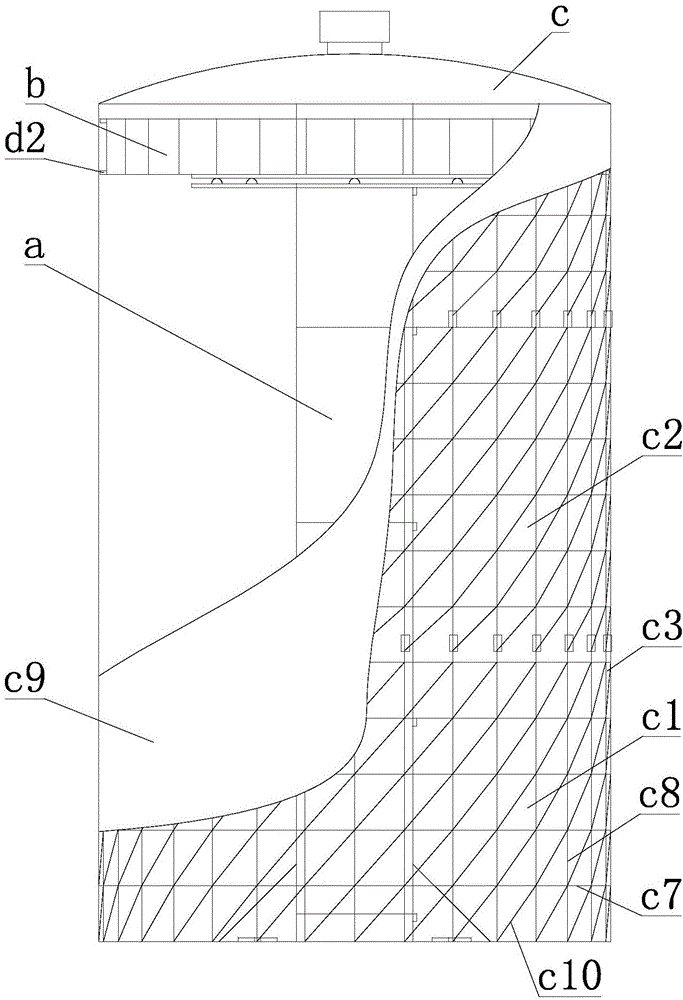

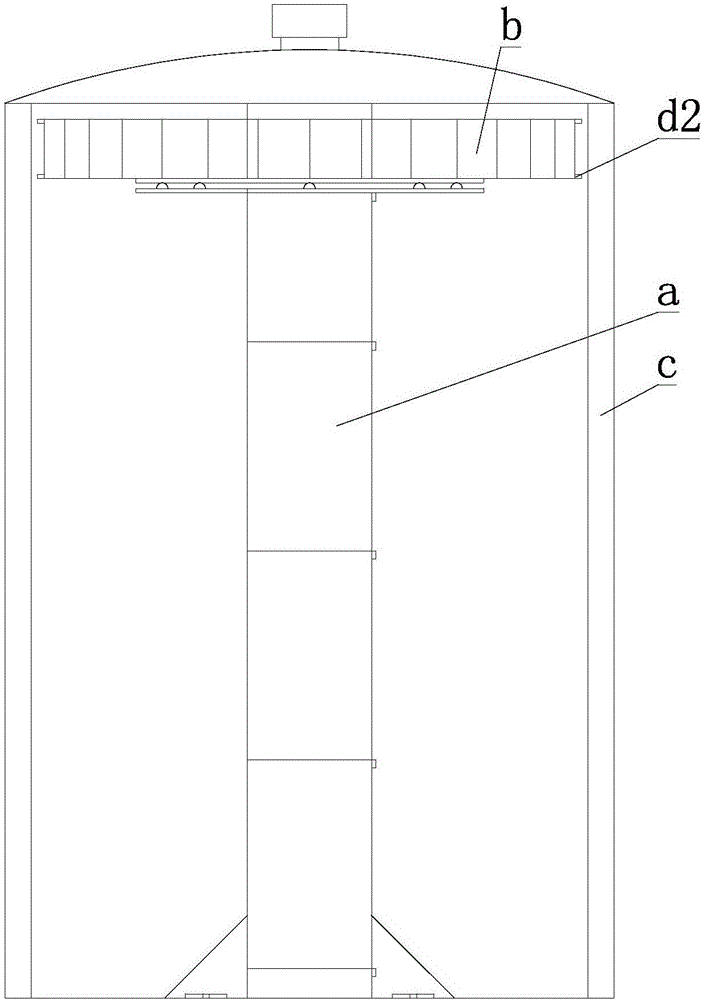

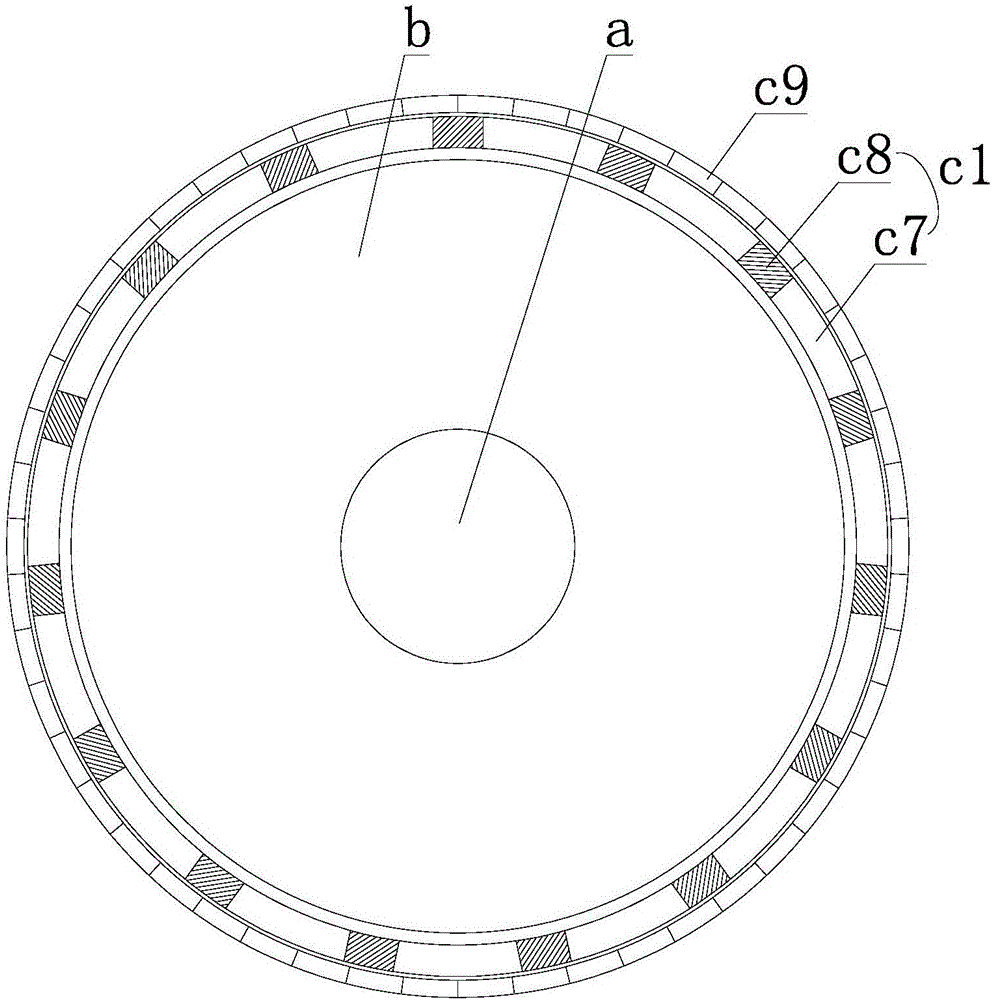

[0031] Such as Figure 1 to Figure 11 As shown, a new gas tank aeroelastic model system, including a spliced cabinet c, the spliced cabinet c is vertically equipped with a central support cylinder a, and the central support cylinder a is axially equipped with multiple test points A piston assembly b is provided outside the central support cylinder a, and the piston assembly b is correspondingly arranged at any of the test positions, and a floating guide d2 is provided between the piston assembly b and the spliced cabinet c.

[0032] The central support cylinder a includes a cylinder body a1, the outer wall of the cylinder body a1 is provided with a piston support a3, and the piston support a3 is detachably connected to the cylinder a1 corresponding to any of the test points, and the piston Assembly b falls on said piston support a3.

[0033] A p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com