Rotating machinery fault qualitative diagnosis method based on convolutional neural network

A technology of convolutional neural network and rotating machinery, applied in neural learning methods, biological neural network models, neural architectures, etc., can solve problems such as difficult practical application and poor diagnostic effect, achieving good results, high accuracy, and simple methods understandable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

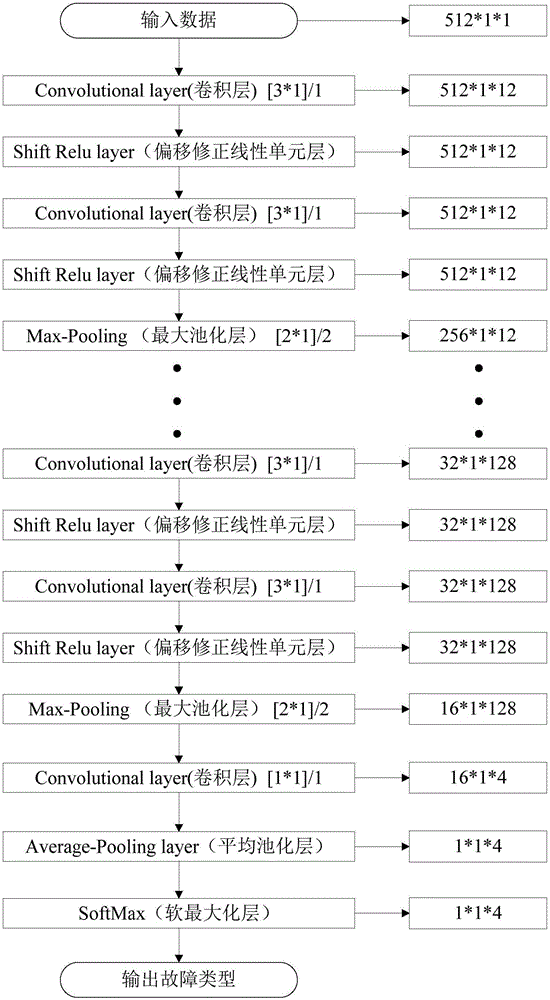

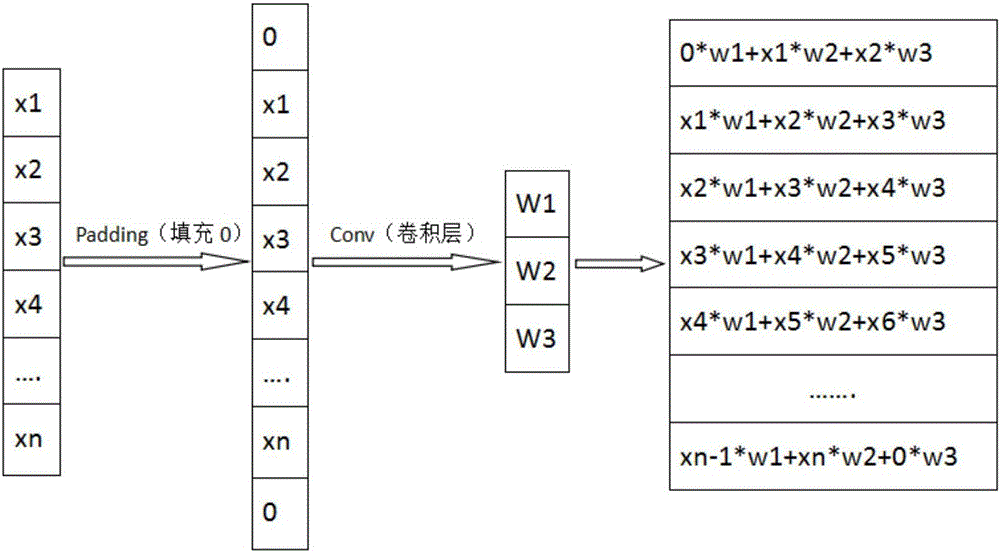

Method used

Image

Examples

Embodiment Construction

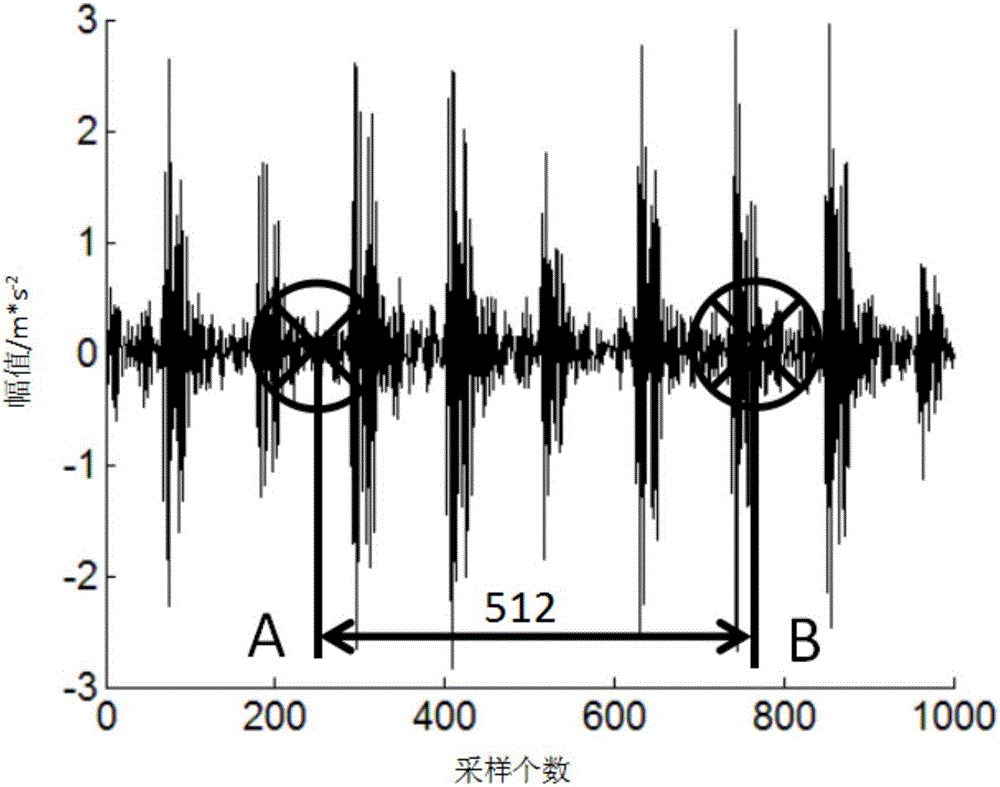

[0028] In this embodiment, the bearing data set collected by the electronic engineering laboratory of Case Western Reserve University in the United States is taken as an example to illustrate the specific diagnosis process and effect of the present invention.

[0029] The acquisition experiment platform of the Electronic Engineering Laboratory of Case Western Reserve University in the United States includes a 2-horsepower motor (left side, 1 horsepower = 746w), a torque sensor (middle), a power meter (right side) and electronic control equipment. The test bench includes the drive shaft end and the output end bearing, and the acceleration sensor is respectively installed at the 12 o'clock position of the drive end and the output end of the motor housing. The vibration signal is collected by a 16-channel DAT recorder, the sampling frequency of the digital signal is 12k, and the fault data of the drive end bearing is also collected at a sampling rate of 48k.

[0030] This embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com