Intelligent tea production line

A production line and tea technology, applied in the field of intelligent tea production line, can solve the problems of manual control, unstable quality, high labor intensity, etc., and achieve the effect of enhancing the degree of intelligence, avoiding secondary pollution, and ensuring the degree of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

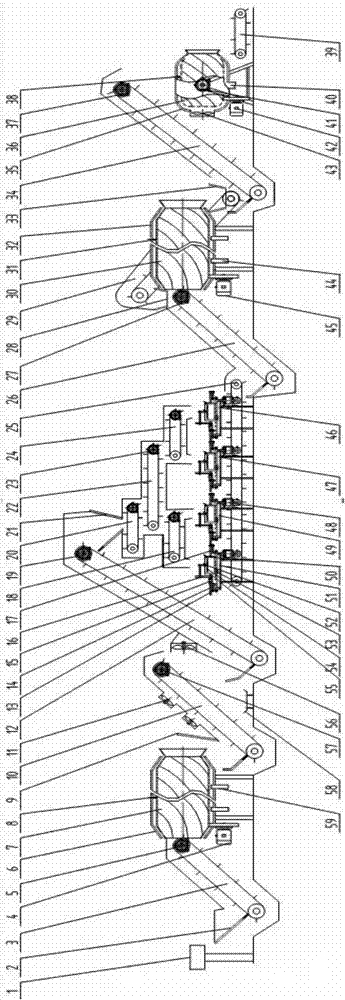

[0029] The intelligent tea production line will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] See attached figure 1 , the tea first enters the finalizing link. Before production and processing, the gas furnace control valve of the green fixing machine is opened first, and the hot gas passes through the heating port 59 of the green fixing machine and enters between the fixed outer cylinder 6 of the green fixing machine and the rotating inner cylinder 7 of the green fixing machine, and the rotating inner cylinder 7 of the green fixing machine Carry out preheating; Put the tea leaves that need to be produced and processed into the feeding conveyor belt 3 of the fixing machine, the feeding conveyor belt drive motor 5 of the fixing machine drives the feeding conveyor belt 3 of the fixing machine, and put the tea leaves into the feeding conveyor hopper 2 of the fixing machine . The green-fixing machine drive motor 4 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com