Ventilation cooling crystallization tower

A ventilation cooling and crystallization tower technology, applied in the direction of heat exchange cooling crystallization, solution crystallization, crystallization separation, etc., can solve problems such as insufficient gas-liquid mixing and contact, affect production operations, and restrict heat exchange effects, etc., to increase the contact surface area, High production efficiency and good product crystallization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, the present invention will be described in further detail through the description of specific embodiments in conjunction with the accompanying drawings, but this is not a limitation of the present invention. Those skilled in the art can make various modifications or improvements according to the basic idea of the present invention, but as long as they do not depart from The basic idea of the present invention is within the scope of the present invention.

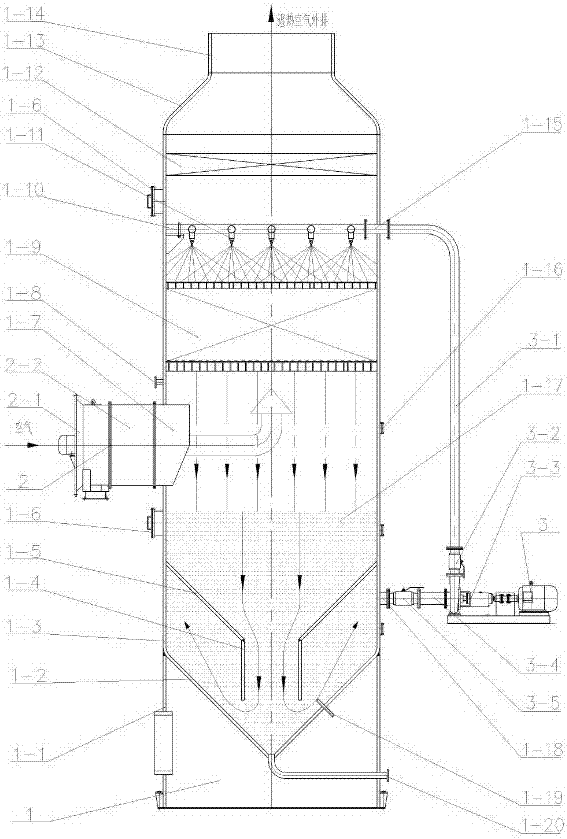

[0024] The invention provides a ventilation cooling crystallization tower. Such as figure 1 As shown, it consists of tower equipment 1, fan equipment 2 and circulating pump equipment 3.

[0025] The tower equipment 1 includes a skirt 1-1, a cone body 1-2, a tower body 1-3, an exhaust cone 1-13, and an exhaust body 1-14; the tower body 1-3 is provided with manholes 1-6, air inlet pipe 1-7, liquid inlet pipe 1-8, circulation liquid inlet pipe 1-15, circulation liquid outlet pipe 1-18, observation mirror 1-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com