Water swelling forming machine for special-shaped pipes

A technology for forming machines and pipe fittings, which is applied in the field of water-swelling forming machines for special-shaped pipe fittings. It can solve the problems of cumbersome adjustment methods and increase the difficulty of adjusting the feeding side cylinder, and achieves the advantages of convenient angle adjustment, small footprint and strong applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings and embodiments.

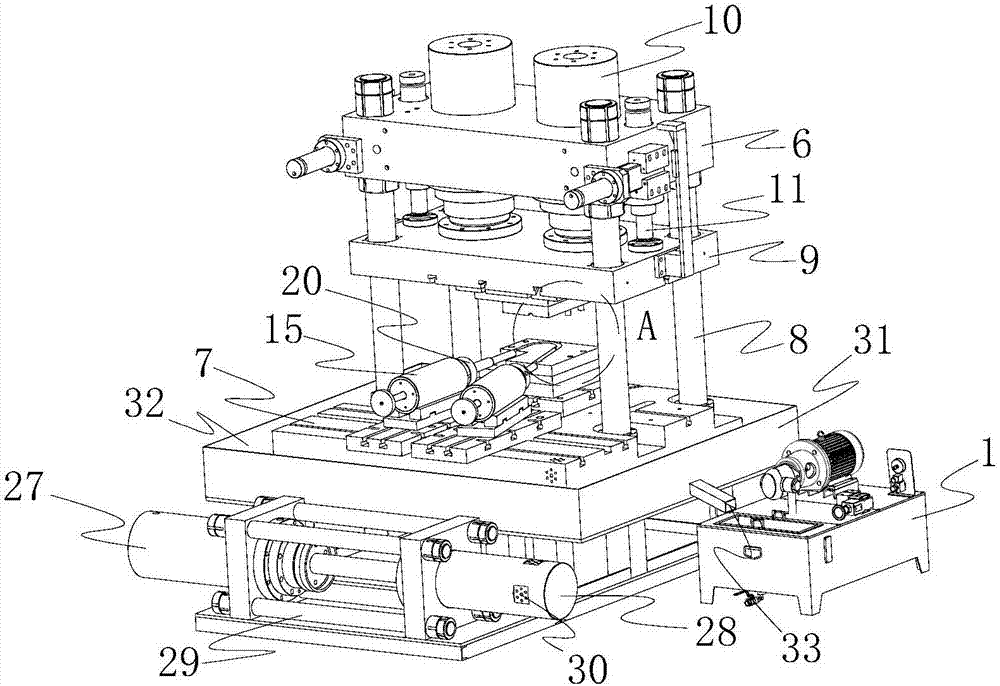

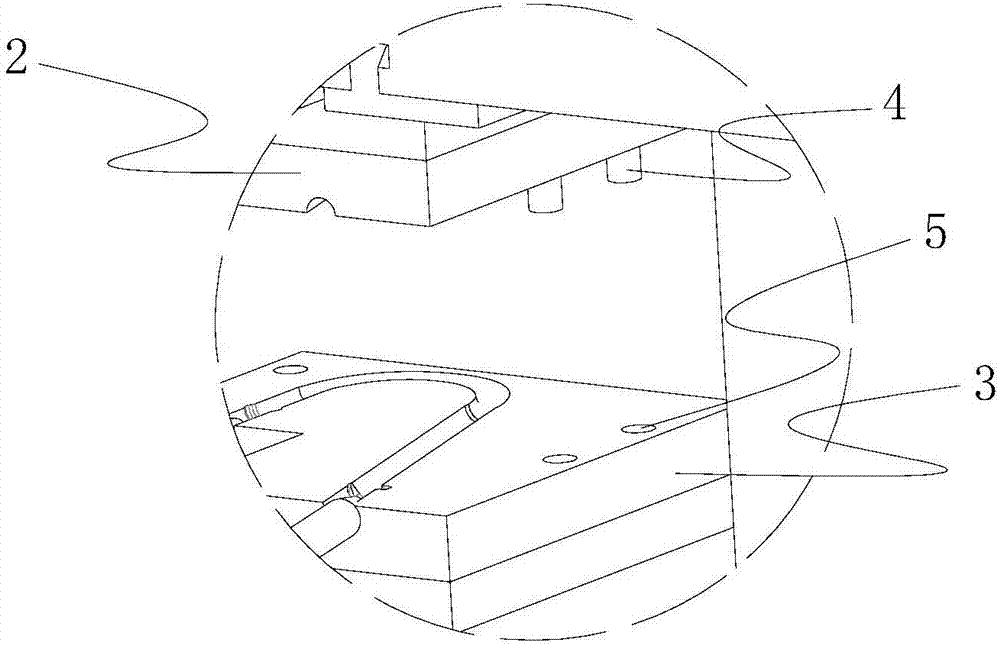

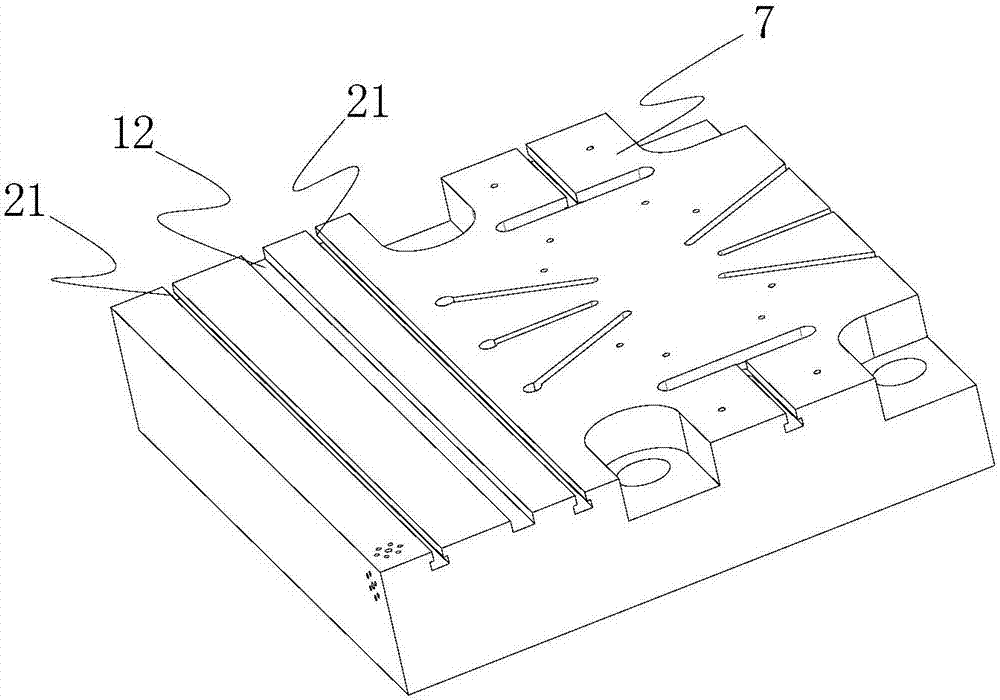

[0025] like Figures 1 to 6 The water swelling forming machine for special-shaped pipe fittings shown includes a frame, a forming liquid storage device, a pressurized injection device and a mold, wherein, in this embodiment, the forming liquid storage device selects the water tank 1, and the water tank 1 stores the workpiece water swelling forming device. Emulsion used; the mold is composed of a forming upper mold 2 and a forming lower mold 3 that cooperate with each other, wherein, the forming upper mold 2 is provided with a plurality of positioning columns 4 for calibrating the forming upper mold 2 and the forming lower mold 3 The lower forming die 3 is provided with a plurality of positioning holes 5 matched with the positioning columns 4 . After the upper forming mold 2 and the lower forming mold 3 are closed, two openings are formed on the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com