Automatic clamping and fixing device for building pipelines

A fixing device and clamping technology, applied in the direction of positioning device, clamping device, clamping, etc., can solve the problem of inconvenient clamping and fixing of pipelines, and achieve the effects of easy popularization and application, convenient operation and simple overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

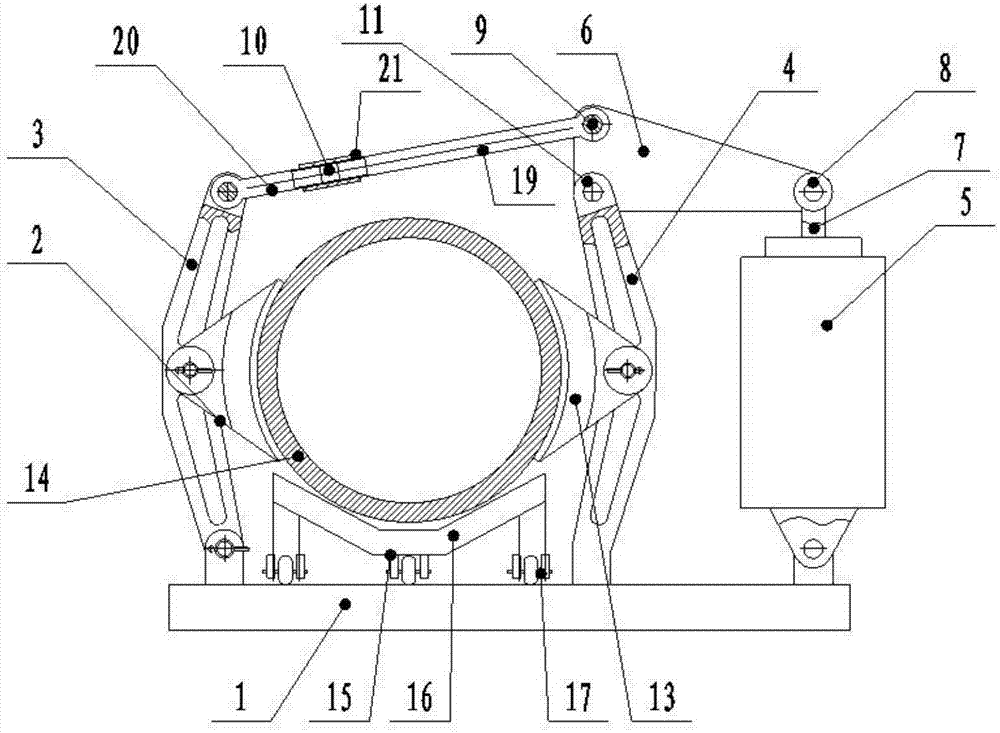

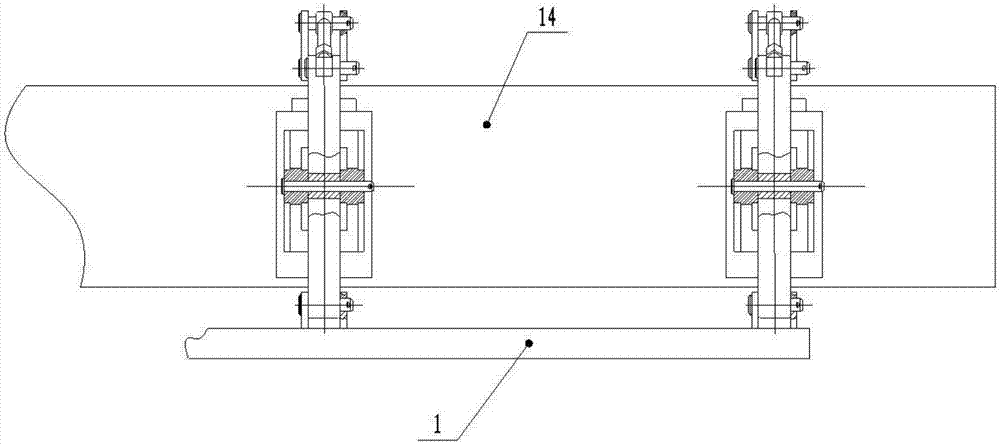

[0025] like figure 1 and 3 As shown, the present invention is an automatic clamping and fixing device for construction pipelines. In this embodiment, the triangular lever 6 is rotated and supported by a support rod 12, which includes a clamping platform 1 and a clamping assembly 2. The clamping platform 1 is evenly distributed. There are multiple sets of clamping components 2, and the number of sets of clamping components 2 depends on the length of the pipeline 14 and the clamping table 1. Generally, the distance between two sets of clamping components 2 is 1m-1.5m. The clamping components 2 include The first clamping arm 3, the second clamping arm 4, the pneumatic pusher 5 and the triangle lever 6, the first clamping arm 3 and the second clamping arm 4 adopt hollow casting, the first clamping arm 3 and the second clamping arm The bottom end of the loading arm 4 is symmetrically hinged on both sides of the clamping table 1, and the outside of the second clamping arm 4 is prov...

Embodiment 2

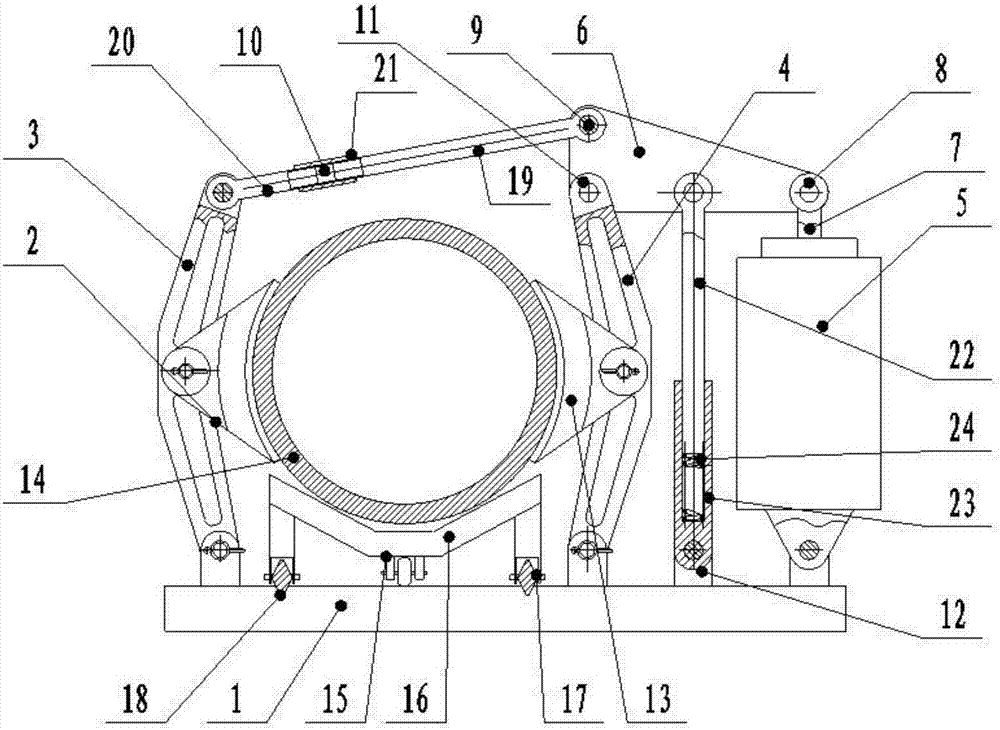

[0031] like figure 2 and 3 As shown, the present invention is an automatic clamping and fixing device for construction pipelines. In this embodiment, the triangular lever 6 is rotated and supported by the second clamping arm 4. Compared with Embodiment 1, the support rod 12 is omitted, and the clamping platform is included. 1 and the clamping assembly 2, multiple sets of clamping assemblies 2 are evenly distributed on the clamping table 1, the number of sets of clamping assemblies 2 depends on the length of the pipeline 14 and the clamping table 1, generally two sets of clamping assemblies 2 The distance between them is 1m-1.5m. The clamping assembly 2 includes a first clamping arm 3, a second clamping arm 4, a pneumatic pusher 5 and a triangular lever 6. The first clamping arm 3 and the second clamping arm 4 adopts hollow casting, the bottom end of the first clamping arm 3 is hingedly installed on the clamping platform 1, and the bottom end of the first clamping arm 4 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com