Method for synthesizing highly ordered super-microporous silicon dioxide

A silica, highly ordered technology, applied in the field of synthesizing ultra-microporous silica, can solve the problems of low degree of commercialization, difficult to buy, high economical and environmental costs, and achieve high pore order and cost. Inexpensive, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

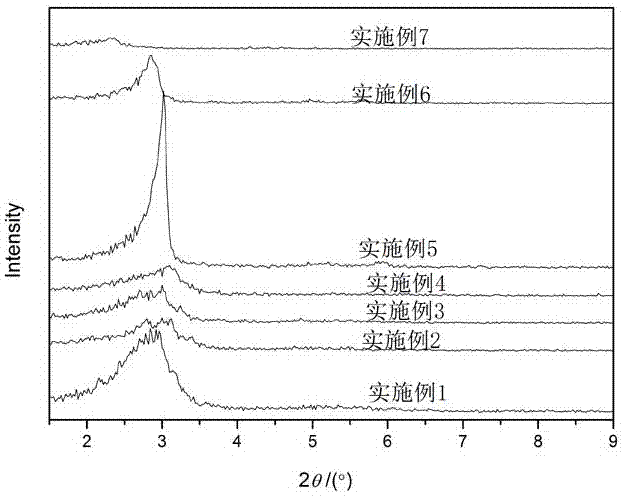

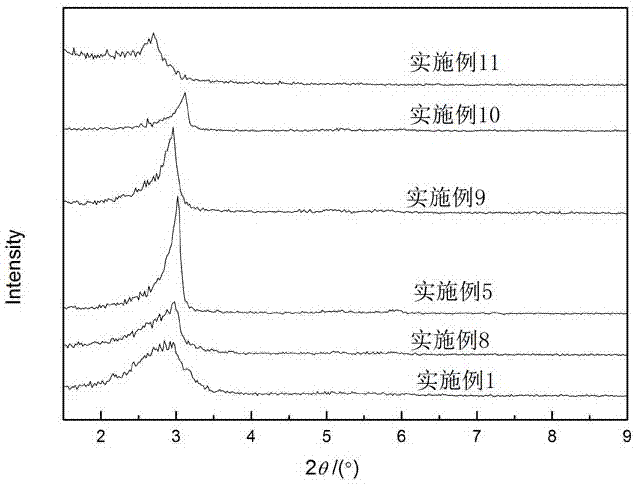

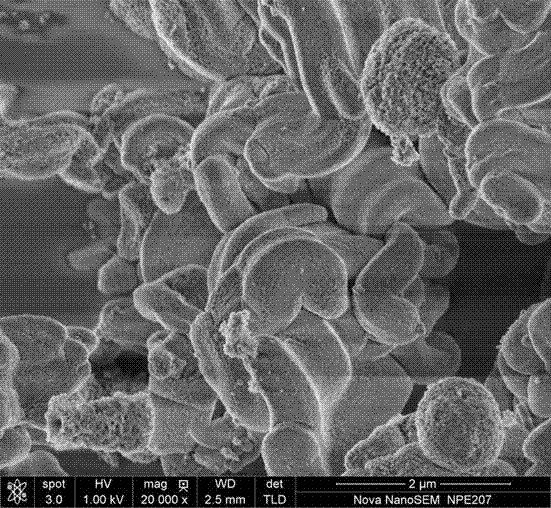

Embodiment 1

[0018] At room temperature, dissolve 1.12g of dedecyltrimethylammonium bromide in 29ml of water, stir for 0.5h to obtain solution A, and take another 1.72g of Na 2 SiO 3 9H 2 Dissolve O in 29ml of water to obtain solution B; quickly mix solutions A and B, and add 2M sulfuric acid solution drop by drop to the above mixture under vigorous stirring until the pH is between 9 and 10; After 72 hours, filter, wash with water, dry in air, and roast at 560°C for 4-5 hours to obtain the product.

Embodiment 2

[0020] At room temperature, get 1.12g dedecyltrimethylammonium bromide (C 10 TAB) and 0.098g sodium acetate were dissolved in 29ml water, stirred for 0.5h to obtain solution A, and another 1.72g Na 2 SiO 3 9H 2 Dissolve O in 29ml of water to obtain solution B; quickly mix solutions A and B, and add 2M sulfuric acid solution drop by drop to the above mixture under vigorous stirring until the pH is between 9 and 10; After 72 hours, filter, wash with water, dry in air, and roast at 560°C for 4-5 hours to obtain the product.

Embodiment 3

[0022] The preparation method is the same as in Example 2, except that "0.098g sodium acetate" in Example 2 is replaced with "0.13g sodium butyrate".

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com