Aqueous epoxy emulsion prepared from emulsifying agent containing isocyanate diepoxy functional groups

A water-based epoxy emulsion and diepoxy functional technology, used in epoxy resin coatings, coatings, etc., can solve the problems affecting the water resistance and salt spray resistance of the coating film, weak epoxy group activity, and insufficient emulsifier reaction. and other problems, to achieve the effect of good emulsification effect, good stability, improved water resistance and salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Monoisocyanate polyoxyethylene monomethyl ether is made of the following raw materials in mass percentage:

[0029] 2,4-Toluene diisocyanate 20%

[0030] Polyethylene glycol monomethyl ether 80%

[0031] Mix 2,4-toluene diisocyanate and polyethylene glycol monomethyl ether, heat up to 100°C for 5 hours, and cool down to room temperature naturally to obtain monoisocyanate polyoxyethylene monomethyl ether.

[0032] (2) The emulsifier is made of the following raw materials in mass percentage:

[0033] Epoxy resin E51 25%

[0034] Monoisocyanate polyoxyethylene monomethyl ether 75%

[0035] Its preparation method is: mix epoxy resin E51 and monoisocyanate polyoxyethylene monomethyl ether, heat up to 80°C and react for 6 hours, and wait for natural cooling to room temperature to obtain the emulsifier.

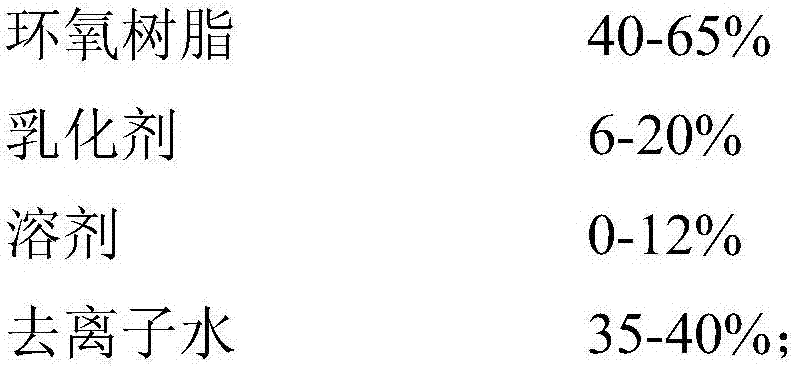

[0036] (3) The water-based epoxy emulsion is made of the following raw materials in mass percentage:

[0037]

[0038] Mix epoxy resin E51, emulsifier, and propyl...

Embodiment 2

[0040] (1) Monoisocyanate polyoxyethylene monomethyl ether is made of the following raw materials in mass percentage:

[0041] 2,4-Toluene diisocyanate 25%

[0042] Polyethylene glycol monomethyl ether 75%

[0043] Mix 2,4-toluene diisocyanate and polyethylene glycol monomethyl ether, heat up to 80°C for 6 hours, and cool down to room temperature naturally to obtain monoisocyanate polyoxyethylene monomethyl ether.

[0044] (2) The emulsifier is made of the following raw materials in mass percentage:

[0045] Epoxy 144 30%

[0046] Monoisocyanate polyoxyethylene monomethyl ether 70%

[0047] Its preparation method is: mix epoxy resin 144 and monoisocyanate polyoxyethylene monomethyl ether, heat up to 100°C and react for 5 hours, and wait for natural cooling to room temperature to obtain the emulsifier.

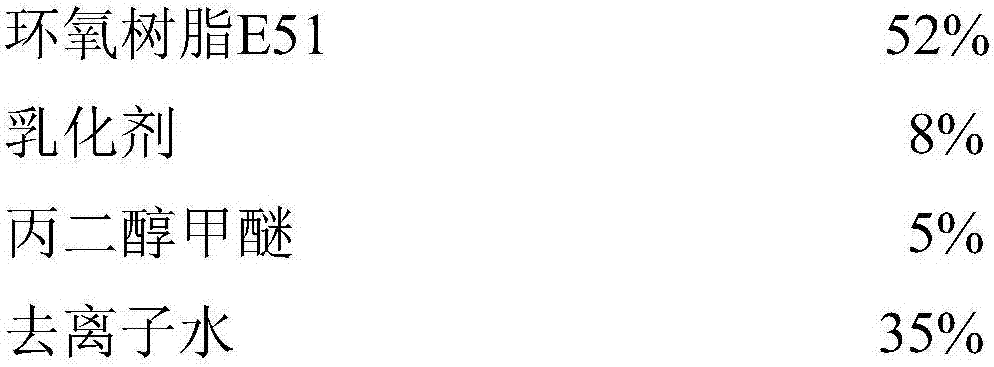

[0048] (3) The water-based epoxy emulsion is made of the following raw materials in mass percentage:

[0049]

[0050] Mix epoxy resin 144, emulsifier, and propylene gl...

Embodiment 3

[0052] (1) Monoisocyanate polyoxyethylene monomethyl ether is made of the following raw materials in mass percentage:

[0053] 2,4-Toluene diisocyanate 15%

[0054] Polyethylene glycol monomethyl ether 85%

[0055] Mix 2,4-toluene diisocyanate and polyethylene glycol monomethyl ether, heat up to 70°C for 6 hours, and cool down to room temperature naturally to obtain monoisocyanate polyoxyethylene monomethyl ether.

[0056] (2) The emulsifier is made of the following raw materials in mass percentage:

[0057] Epoxy resin E20 20%

[0058] Monoisocyanate polyoxyethylene monomethyl ether 80%

[0059] The preparation method is as follows: mix epoxy resin E20 and polyoxyethylene monomethyl ether monoisocyanate, heat up to 90°C and react for 4 hours, and cool naturally to room temperature to obtain the emulsifier.

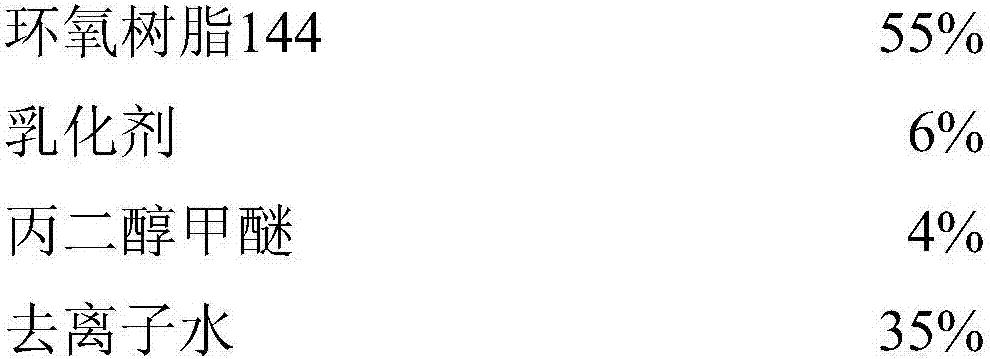

[0060] (3) The water-based epoxy emulsion is made of the following raw materials in mass percentage:

[0061]

[0062] Mix epoxy resin E20, emulsifier, and propyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com