Mechanical microseism source, and microseism monitoring system and using method thereof

A technology for microseismic monitoring and seismic source, applied in seismology, measuring device, geophysical measurement, etc., can solve the problems of costing a lot of manpower, material and financial resources, low accuracy of manual picking, mixed blasting events, etc. Safe and fast process with little impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

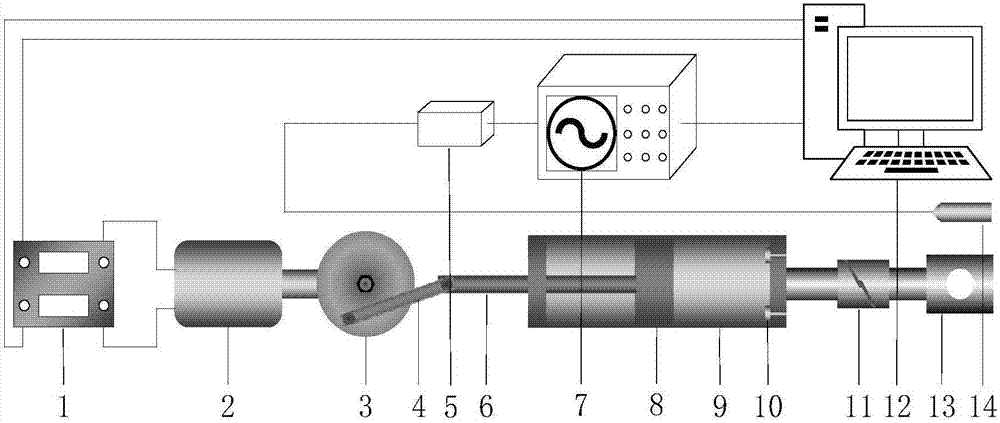

[0040]A mechanical microseismic source, the microseismic source includes a driving power, a pressure accumulator cavity, a safety valve, and an energy projecting head; the driving power includes a motor (2), a flywheel (3), and a crankshaft (4); the pressure accumulating The cavity includes a piston (8) and a cylinder (9); the motor (2) is electrically connected to the electronic switch (1), and the electronic switch (1) controls the on-off of the power supply of the motor (2), and the output of the motor (2) The flywheel (3) is driven, and the flywheel (3) is connected to one end of the crankshaft (4); the other end of the crankshaft (4) is connected to the connecting rod (6) arranged on the piston (8), and the driving piston (8) is connected to the cylinder ( 9) reciprocating motion; on the cylinder (9), there is also 1 air outlet and 2 air inlets; the air outlet is connected with a safety valve (11) and an energy shooter (13) in sequence; the 2 Air intake valves (10) are re...

Embodiment 2

[0043] A mechanical microseismic source, the difference from Embodiment 1 is:

[0044] An electronic switch (1) is connected to three driving powers at the same time, and a network is formed to realize simultaneous triggering of multiple seismic sources; the driving power is consistent with the number of pressure storage chambers.

Embodiment 3

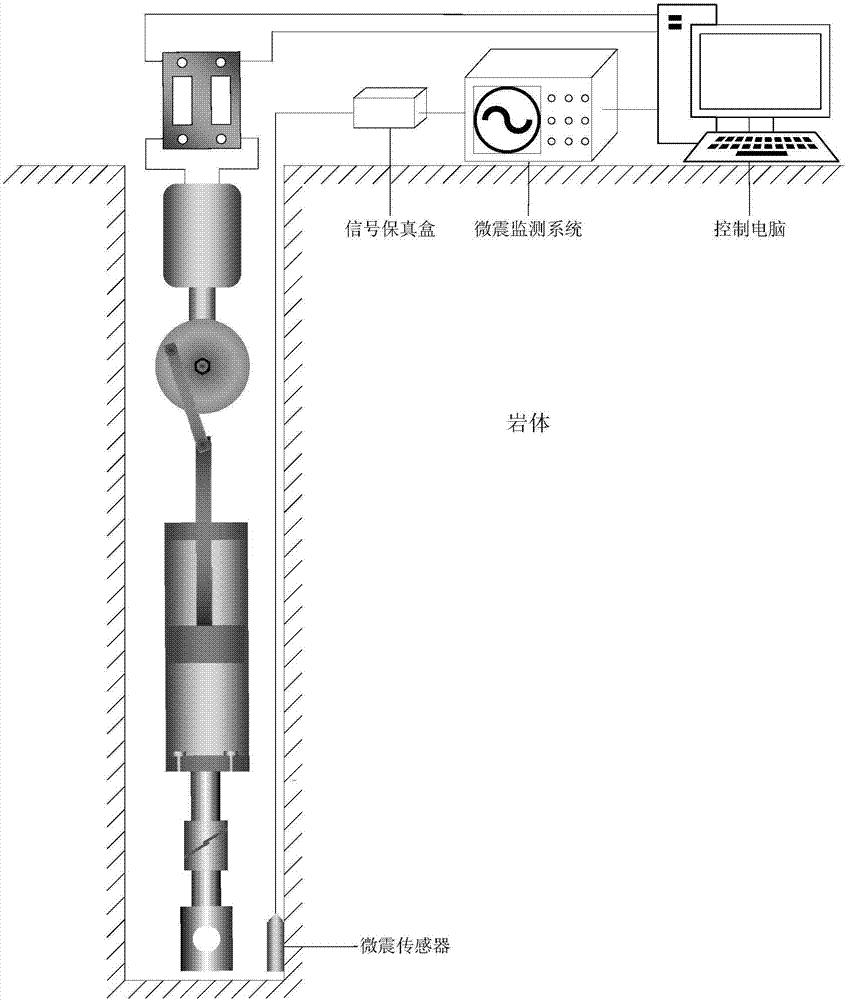

[0046] A microseismic monitoring system comprising a mechanical microseismic source, comprising a microseismic source, a signal fidelity box (5), a microseismic signal monitoring device (7), a control computer (12), and a microseismic sensor (14), characterized in that: the microseismic source The electronic switch (1) is electrically connected to the control computer (12); one end of the microseismic signal monitoring device (7) is electrically connected to the control computer (12), and the other end is electrically connected to the signal preservation box (5) and the microseismic sensor (14) successively. Connected, the microseismic sensor (14) is arranged on the periphery of the energy-emitting head in the micro-seismic source, with an average distance of 50 meters from the energy-emitting head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com