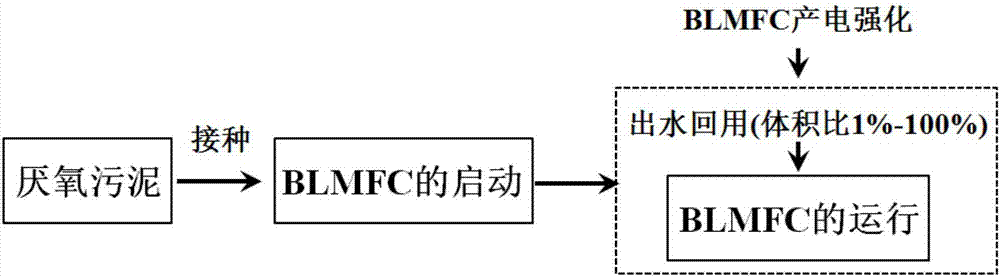

Method for improving power generation performance of buffer-less microbial fuel cell (BLMFC)

A fuel cell and electrical performance technology, applied in the field of environmental biology, can solve the problems of limited buffer capacity and low concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0014] Place the graphite felt anode and the activated carbon air cathode in a 28mL MFC reactor, use the sludge from the anaerobic pool of the sewage treatment plant as the inoculum, add PBS buffer solution (50mM) containing 1g / L sodium acetate, and connect an external resistance of 500Ω , inoculate at room temperature, and the reactor starts up successfully when the power generation of the MFC system is greater than 100mV. Suck out the sludge, add NaCl solution (50mM) containing 1g / L sodium acetate as anolyte, connect external resistance of 500Ω, and inoculate at room temperature. The anolyte is reused at a volume ratio of 30%, that is, at the end of each power generation cycle, 30% of the volume of the anolyte is taken out and re-added to the MFC reactor, followed by adding a high-concentration sodium acetate solution and using NaCl solution (50mM) Fill the MFC reactor fully and connect the external circuit to generate electricity. After 5 cycles of reuse, the pH value of t...

example 2

[0016] Place the graphite felt anode and the activated carbon air cathode in a 1L MFC reactor, use the sludge from the anaerobic pool of the sewage treatment plant as the inoculum, add PBS buffer solution (50mM) containing 1g / L sodium acetate, and connect an external resistance of 500Ω , inoculate at room temperature, and the reactor starts up successfully when the power generation of the MFC system is greater than 100mV. The sludge was sucked out, and a NaCl solution (50mM) containing 1g / L glucose was pumped in by a peristaltic pump as the anolyte, connected to an external resistance of 500Ω, and operated continuously at room temperature. The effluent is directly pumped into the reactor with a peristaltic pump so that the volume of recycled anolyte in the reactor accounts for 50% of the total volume of the reactor, and an external circuit is connected to generate electricity. After 6 days of operation, the pH value of the anolyte fluctuates around 7.6, and the HCO 3 - The c...

example 3

[0018] The carbon fiber brush anode and the Pt / C modified carbon cloth air cathode were placed in a 5L MFC reactor, and the anaerobic pool sludge of the sewage treatment plant was used as the inoculum, and a phosphate buffer solution (50mM) containing 1g / L sodium acetate was added , an external 500Ω external resistance, inoculation at room temperature, when the power generation of the MFC system is greater than 100mV, the reactor starts successfully. Suck out the sludge and pump it into domestic sewage with a peristaltic pump (COD is 400mg·L -1 ) as the anolyte, connected to an external resistance of 500Ω, and operated continuously at room temperature. The effluent is directly pumped into the reactor with a peristaltic pump so that the volume of recycled anolyte in the reactor accounts for 40% of the total volume of the reactor, and an external circuit is connected to generate electricity. After 8 days of operation, the pH value of the anolyte fluctuated around 8.3, and the H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com