Thermal package device of lithium battery cover cap

A lithium battery and thermal packaging technology, which is applied in non-aqueous electrolyte storage battery, electrolyte storage battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of over-voltage and down-voltage, inconsistent height, not in place, etc., to achieve precise positioning of feeding, The effect of preventing offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

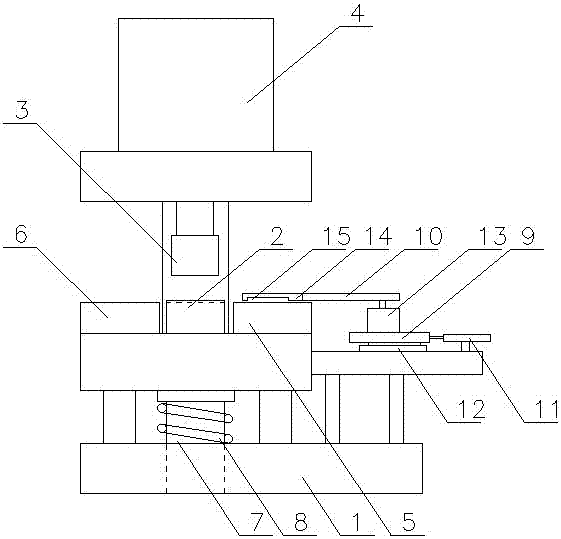

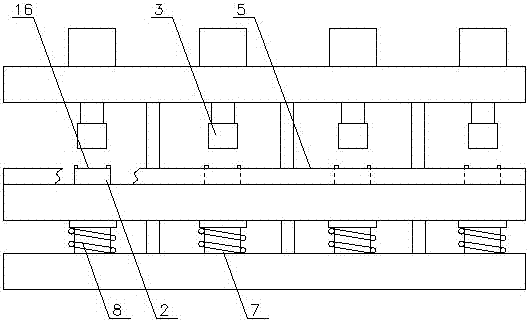

[0016] As shown in the figure, the lithium battery cap heat sealing device includes a workbench 1. A row of press seats 2 arranged at equal intervals are installed on the workbench 1. A thermal pressing head 3 is arranged directly above each press seat 2. The hot press The head 3 is pressed down and reset driven by the vertical cylinder 4. The front and rear sides of the press seat 2 are respectively equipped with a loading line 5 and an unloading line 6. Arranged close to each other, the distance between each press seat 2 is an integer multiple of the diameter of the cap part. The press seat 2 is sleeved on the vertical guide post 7, and the guide post 7 is fixedly installed on the workbench. A spring 8 is squeezed between the bottom of the press seat 2 and the workbench 1, and the spring 8 is sleeved on the guide post 7. The press seat 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com