Lipstick container

A lipstick and container technology, applied in the field of lipstick containers, can solve the problems of pollution, loss of cover, inconvenient use, etc., and achieve the effects of convenient use, compact structure and small appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

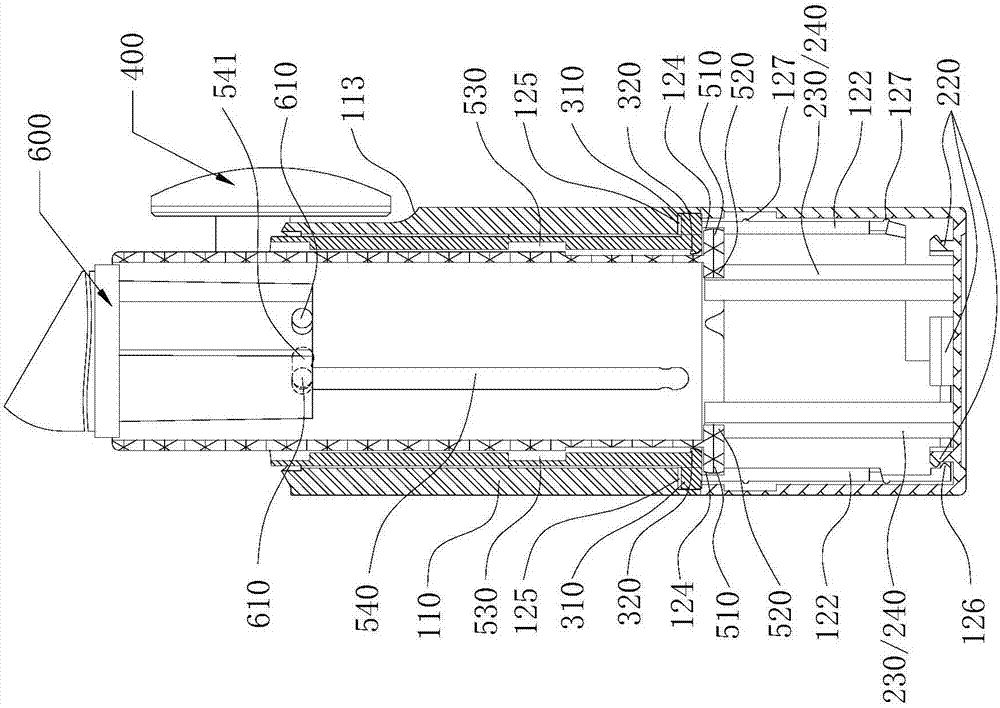

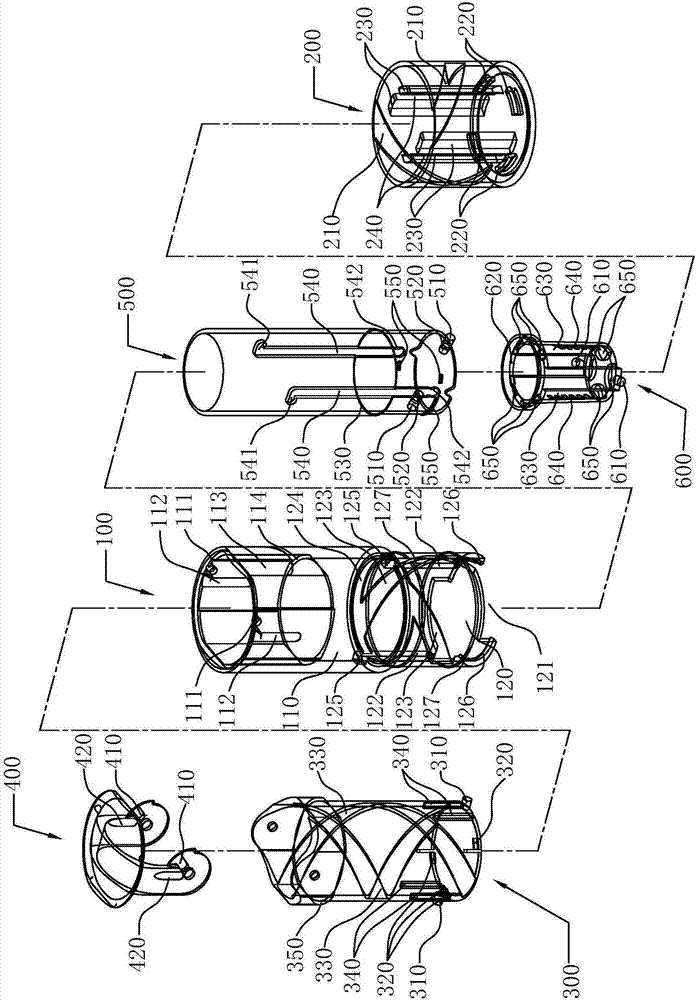

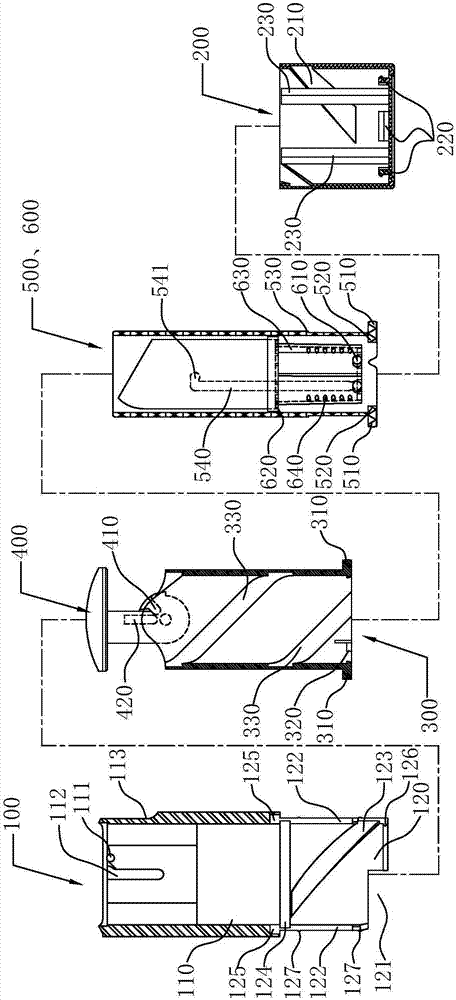

[0042] Such as Figure 1 to Figure 7 The shown lipstick container includes a container outer cylinder 100, a container base 200, a lifting seat 300, a lifting cover 400 capable of covering the top opening of the container outer cylinder, a guide tube 500 and a lipstick transport cup 600;

[0043] The container outer cylinder 100 includes a guide cylinder 110 and a base installation cylinder 120 located below the guide cylinder. The inner wall of the guide cylinder 110 is provided with flip guide nails 111. The bottom of the base installation cylinder 120 is provided with an assembly gap 121. The base The mounting cylinder 120 is symmetrically provided with two lifting seat guide grooves 122 along the axial direction, and the inner wall is provided with two guide cylinder helical guide grooves 123 staggered by 180 degrees. The direction and pitch of the two guide cylinder helical guide grooves 123 are the same. The inner wall of the base mounting cylinder 120 is provided with a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap