Microfluidic liquid film chiral separation method

A chiral separation and microfluidic technology, applied in the field of membrane separation, can solve problems such as poor stability, product contamination, and reduced efficiency, and achieve the effects of low cost, simple operation, and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

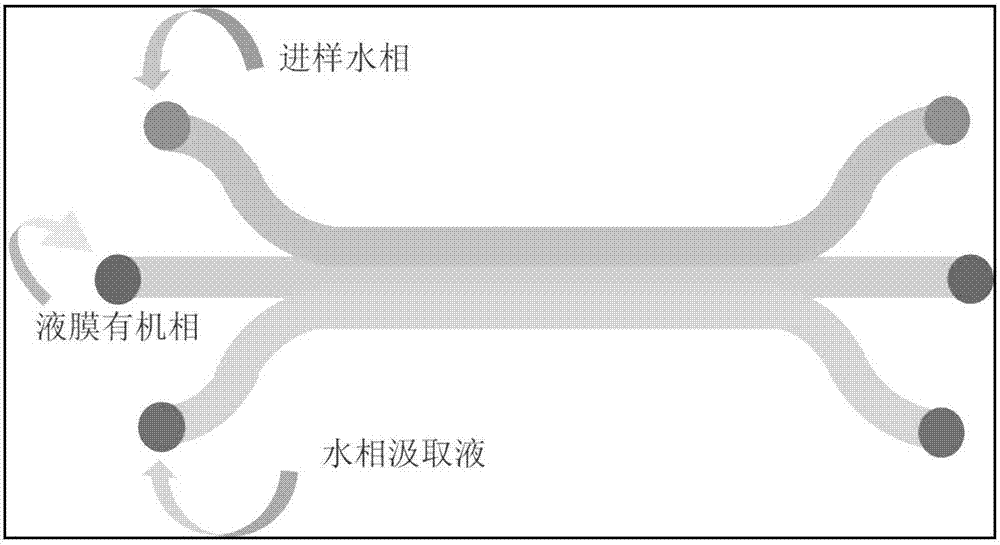

[0023] This embodiment includes the following steps: as shown in the figure 1, (1) prepare a microfluidic liquid membrane separation channel with PDMS polymer material, adopt α-cyclodextrin as chiral selector, its concentration is 0.1mM, Aliquat 336 is used as For the transfer of molecules, diesel oil is used as the organic phase liquid membrane, deionized water is used as the drawing solution, and the concentration of L,D-tryptophan racemate is 0.1mM. At the beginning of the experiment, the flow rate of the middle laminar flow, that is, the diesel liquid film, was controlled to be 5 μL / m, the flow rate of the outer layer of laminar flow, that is, deionized water, was 20 μL / m, and the flow rate of the other outer layer, that is, L, D-tryptophan, was 20 μL / m.

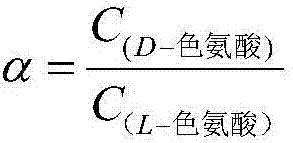

[0024] (2) Determination of the concentration of L-tryptophan and D-tryptophan in the draw solution by liquid chromatography, thereby calculating the size of the chiral separation selectivity coefficient, the test result...

Embodiment 2

[0026] This embodiment includes the following steps: as shown in the figure 1, (1) prepare a microfluidic liquid membrane separation channel with PDMS polymer material, adopt β-cyclodextrin as chiral selector, its concentration is 0.5mM, Aliquat 336 is used as For the transfer of molecules, diesel oil is used as the organic phase liquid membrane, deionized water is used as the drawing solution, and the concentration of L,D-tryptophan racemate is 0.1mM. At the beginning of the experiment, the flow rate of the middle laminar flow, that is, the diesel liquid film, was controlled to be 5 μL / m, the flow rate of the outer layer of laminar flow, that is, deionized water, was 20 μL / m, and the flow rate of the other outer layer, that is, L, D-tryptophan, was 20 μL / m.

[0027] (2) Determination of the concentration of L-tryptophan and D-tryptophan in the drawing solution, thereby calculating the size of the chiral separation selectivity coefficient, the test results are shown in Table 1...

Embodiment 3

[0029] This embodiment includes the following steps: as shown in the figure 1, (1) Prepare a microfluidic liquid membrane separation channel with PDMS polymer material, using γ-cyclodextrin as a chiral selector at a concentration of 0.1mM, and Aliquat336 as a delivery Molecules, diesel oil as the organic phase liquid film, deionized water as the draw solution, the concentration of L, D-tryptophan racemate is 0.1mM. At the beginning of the experiment, the flow rate of the middle laminar flow, that is, the diesel liquid film, was controlled to be 5 μL / m, the flow rate of the outer layer of laminar flow, that is, deionized water, was 20 μL / m, and the flow rate of the other outer layer, that is, L, D-tryptophan, was 20 μL / m.

[0030] (2) Determination of the content of L-tryptophan and D-tryptophan in the drawing solution, thereby calculating the size of the chiral separation selectivity coefficient, the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com