A kind of preparation method of temperature buffer type polyvinyl alcohol film

A technology of polyvinyl alcohol film and polyvinyl alcohol, applied in the field of packaging materials, to achieve the effect of reducing loss, small thickness, and reducing food quality changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

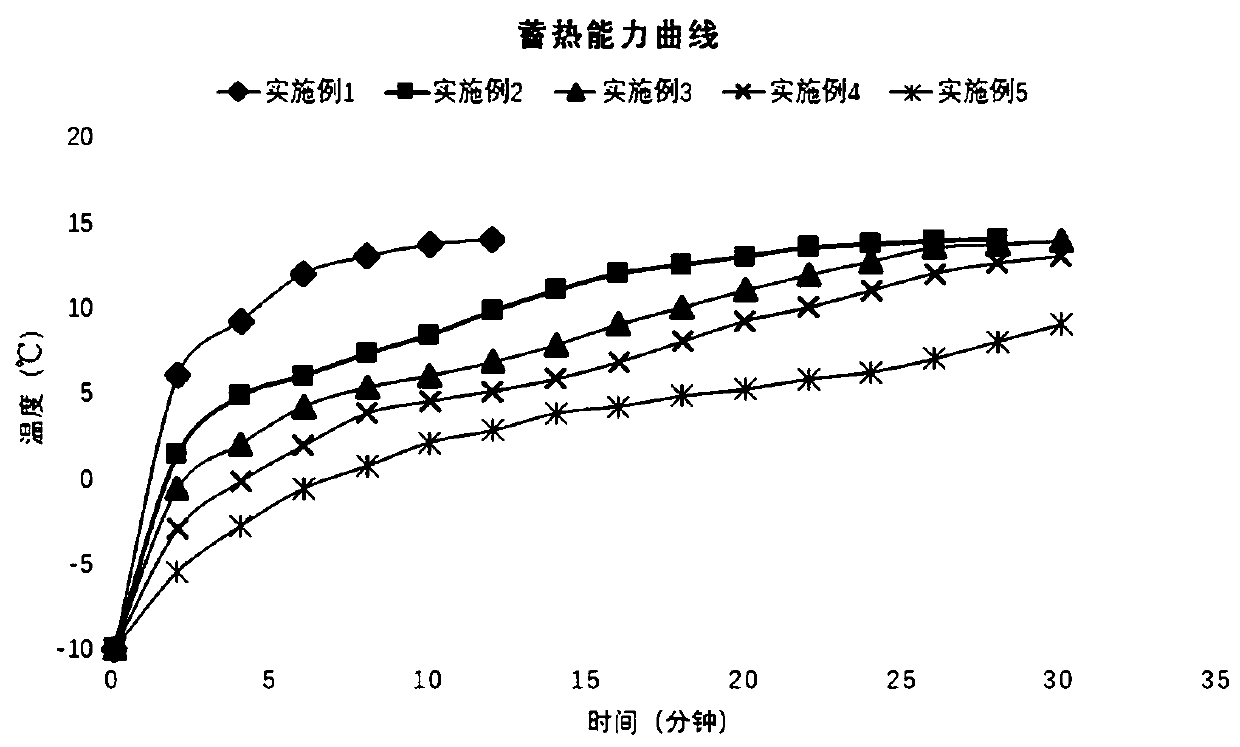

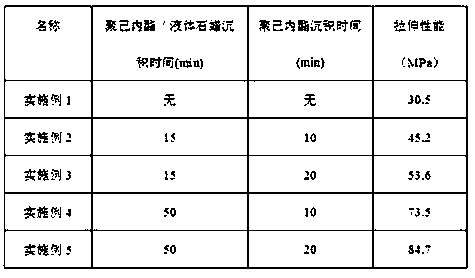

Examples

preparation example Construction

[0029] (1) Preparation of polyvinyl alcohol sticky film:

[0030] Weigh 24g of PVA and place it in a beaker, add 200ml of deionized water into the beaker and place it in a high-temperature cooking pot under high pressure at 121°C for 50 minutes. After the temperature in the cooking pot drops to 90°C, take out the beaker and stir it with a glass rod for 5 minutes. , placed in a heat-collecting constant temperature heating magnetic stirrer at 90°C, adjust the rotation speed to 50rpm and stir for 30 minutes, add 1ml glycerin as a plasticizer with a pipette gun while magnetically stirring in a water bath, and continue stirring for 30 minutes to finally obtain PVA Mother liquor, the PVA mother liquor solution is cast on a glass plate, the size of the glass plate is 30×30cm, the temperature of the glass plate is 60°C, keep the temperature of the glass plate constant, and obtain a viscous polyvinyl alcohol film after standing for 20 minutes, which is ready for use;

[0031] (2) Prepa...

Embodiment 1

[0040] Weigh 24g of PVA and place it in a beaker, add 200ml of deionized water into the beaker and place it in a high-temperature cooking pot under high pressure at 121°C for 50 minutes. After the temperature in the cooking pot drops to 90°C, take out the beaker and stir it with a glass rod for 5 minutes. , placed in a heat-collecting constant temperature heating magnetic stirrer at 90°C, adjust the rotation speed to 50rpm and stir for 30 minutes, add 1ml glycerin as a plasticizer with a pipette gun while magnetically stirring in a water bath, and continue stirring for 30 minutes to finally obtain PVA Mother liquor, cast the PVA mother liquor solution on a glass plate, the size of the glass plate is 30×30cm, the temperature of the glass plate is 60°C, keep the temperature of the glass plate constant, and obtain a polyvinyl alcohol film after standing for 50 minutes, peel off the film and put it in Store in a vacuum-sealed high-barrier bag at 4°C.

[0041] The mechanical proper...

Embodiment 2

[0043] Weigh 24g of PVA and place it in a beaker, add 200ml of deionized water into the beaker and place it in a high-temperature cooking pot under high pressure at 121°C for 50 minutes. After the temperature in the cooking pot drops to 90°C, take out the beaker and stir it with a glass rod for 5 minutes. , placed in a heat-collecting constant temperature heating magnetic stirrer at 90°C, adjust the rotation speed to 50rpm and stir for 30 minutes, add 1ml glycerin as a plasticizer with a pipette gun while magnetically stirring in a water bath, and continue stirring for 30 minutes to finally obtain PVA Mother liquor, the PVA mother liquor solution is cast on a glass plate, the size of the glass plate is 30×30cm, the temperature of the glass plate is 60°C, keep the temperature of the glass plate constant, and after standing for 20 minutes, a viscous polyvinyl alcohol film is obtained, which is ready for use.

[0044] Weigh 75ml of chloroform and place it in a beaker, then add 25m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com